-

WhatsApp

-

Email

Vacuum drying is also called analytical drying and decompression drying. It is a method of placing the material under vacuum negative pressure, and appropriately heating it to reach the boiling point under negative pressure or cooling the material to solidify the material and then drying the material through the melting point (that is, vacuum drying). Freeze drying, a type of vacuum drying) drying method. From the point of view of environmental protection, a vacuum drying oven for flammable solvents is also called "green drying". It can play a certain role in the disinfection and sterilization of medicines, food and biological products, and can reduce the chance of contamination of materials or inhibit the growth of certain bacteria.

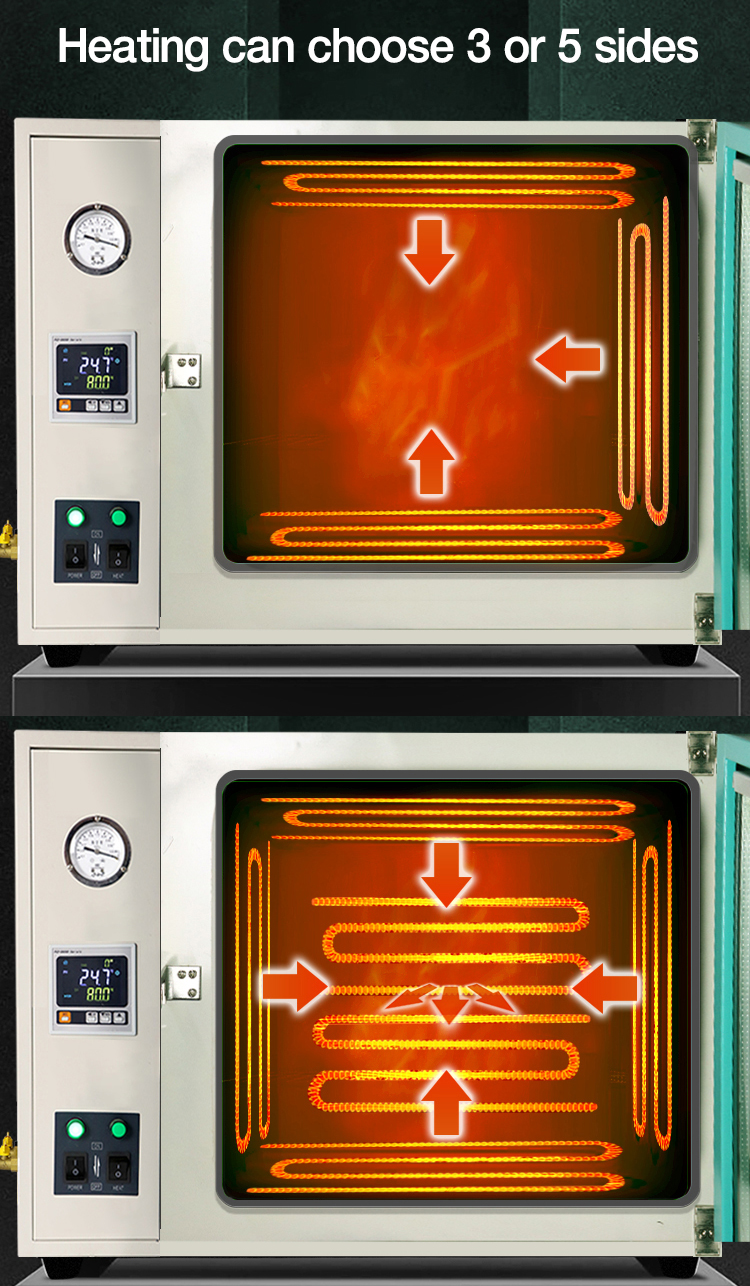

The shell of the electric heating vacuum oven for sale is punched, folded and welded by steel plate. The interior of the studio is provided with a sample shelf for placing various test items, and mica heaters are installed around the outer wall of the studio. The front panel of the electrical box is equipped with vacuum gauges, temperature control instruments and control switches. The electrical components are installed in the electrical box.

Operating procedures:

1. Tightly close the box door and the air release valve. There are bolts on the box door so that the box door can be tightly combined with the silicone sealing strip.

2. Connect the vacuum pump to the vacuum valve, open the vacuum valve, and evacuate

3. According to the performance of the vacuum pump, the limit value of the vacuum pump when the pressure gauge is pumped shall prevail.

4. The drying cycle of the materials in our institute should be observed at regular intervals, and the calorimeter, the thermometer, and the changes in the box will be processed.

5. After the drying is completed, first open the air release valve to release the gas inside, and then open the door of the dzf 6050 vacuum oven to take out the material.

Precautions for use:

1. The shell of the vacuum box must be effectively grounded to ensure safe use.

2. There is no explosion-proof and anti-corrosion treatment in the vacuum drying oven for flammable solvents studio, and items that are inflammable, explosive, and prone to corrosive gases are not allowed to be dried.

3. The vacuum pump cannot work for a long time. Therefore, when the vacuum degree reaches the requirements of the dry goods, the vacuum valve should be closed first, and then the power of the vacuum pump should be turned off. When the vacuum degree is less than the requirements of the dry goods, the vacuum valve and the power of the vacuum pump should be turned on, and the vacuum should be continued. This extends the life of the vacuum pump.

4. If the dry items are wet, it is best to add a filter between the vacuum oven for sale and the vacuum pump to prevent the wet gas from entering the vacuum pump and causing the vacuum pump to malfunction.

5. If the dry items are changed to be light in weight and small in size (small particles) after drying, a barrier net should be added to the vacuum port in the workroom to prevent the vacuum pump (or solenoid valve) from being damaged by the inhalation of dry matter.

6. After the dzf 6050 vacuum oven is used many times, the phenomenon that it cannot be vacuumed will occur. At this time, the door seal should be replaced or the extension distance of the door buckle on the box should be adjusted to solve it. At this time, remove the back cover of the box and use an Allen wrench to loosen the heater base and replace the seal. Ring or tighten the heater base to fix it.

7. If the rubber stopper of the air release valve is difficult to rotate, it can be lubricated with an appropriate amount of grease inside. (like Vaseline)

8. The vacuum drying oven should be kept clean frequently.

9. If the dzf 6050 vacuum oven is not used for a long time, wipe the exposed electroplating parts and apply neutral grease to prevent corrosion.