-

WhatsApp

-

Email

DZF series vacuum drying oven adds vacuum conditions on the basis of high temperature drying, which greatly reduces the boiling point and vapor pressure, provides a dust-free, vortex-free drying process and a mild environment for the test and heating process, and also makes the solvent vapor Easy to collect, discharge or reuse. In addition, storage, heating, testing and drying are carried out in an environment without oxygen or filled with inert gas, so the experimental samples are not easily oxidized.

The vacuum pump used in the vacuum drying oven is a rotary vane vacuum pump, and most of the rotary vane vacuum pumps are small and medium-sized vacuum pumps. There are two types of rotary vane vacuum pumps: single-stage rotary vane vacuum pumps and two-stage vacuum pumps. The so-called two-stage rotary vane vacuum pump is to connect two single-stage pumps in series structurally. Generally, it is made into two stages to obtain a higher vacuum degree. Rotary vane vacuum pumps can be used alone, or as backing pumps for booster pumps, diffusion pumps, molecular pumps and titanium pumps.

The vacuum pump used in the vacuum drying oven is a rotary vane vacuum pump, and most of the rotary vane vacuum pumps are small and medium-sized vacuum pumps. There are two types of rotary vane vacuum pumps: single-stage rotary vane vacuum pumps and two-stage vacuum pumps. The so-called two-stage rotary vane vacuum pump is to connect two single-stage pumps in series structurally. Generally, it is made into two stages to obtain a higher vacuum degree. Rotary vane vacuum pumps can be used alone, or as backing pumps for booster pumps, diffusion pumps, molecular pumps and titanium pumps.

DZF-6090 vacuum drying oven with pump features:

1. The cuboid studio maximizes the effective volume, and the microcomputer temperature controller ensures accurate and reliable temperature control.

2. Toughened, bulletproof double-layer glass door can observe the objects in the working room clearly at a glance, and can fill the interior with inert gas.

3. The closed tightness of the box door can be adjusted, and the integrally formed synthetic silicon door seal ensures high vacuum inside the box.

4. The studio is made of stainless steel plate material to ensure that the product is durable and easy to clean.

5. Storage, heating, testing and drying can be carried out in an environment without oxygen or filled with inert gas, which will not cause oxidation.

6. High temperature resistant silicone rubber door seal formed by one-time casting

7. Lightly touch the interlocking double solenoid valve to realize vacuum pumping and pressure relief

8. The vacuum drying oven with pump has the functions of LED display, temperature correction, over-temperature alarm, etc.

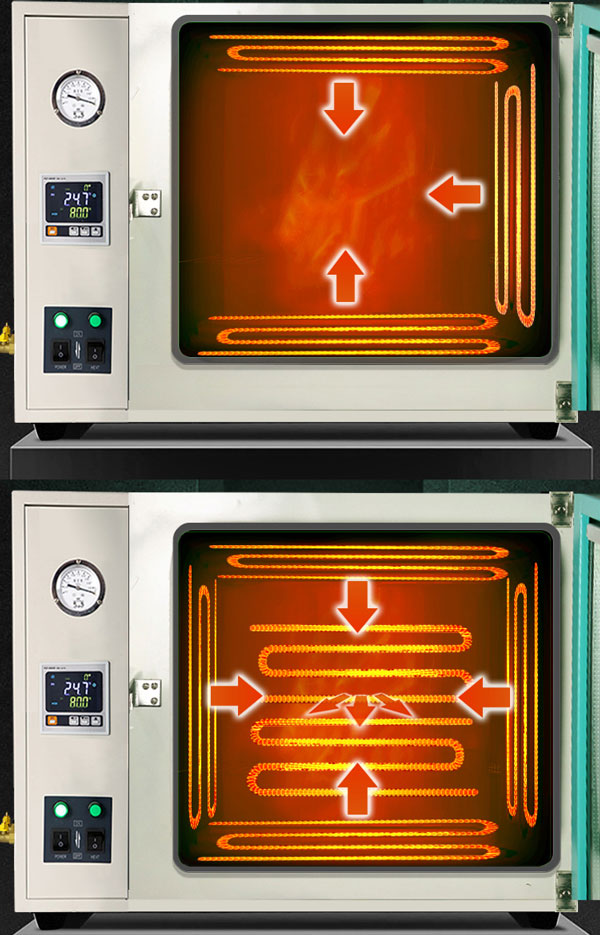

9. The heating element is located on the inner partition of the box, and the heating time is shortened by 50% compared with the traditional vacuum drying box (except 6050).

10. Large-screen LCD display, multiple sets of data displayed on one screen, menu-style operation interface, easy to understand and easy to operate.

11. The aluminum shelf stamped by special process has high temperature non-oxidation and fast heat conduction. Minimize heat loss

Main features of DZF-6090 vacuum drying oven with pump:

1. The vacuum drying oven with pump is specially designed for drying heat-sensitive, easily decomposed and easily oxidized substances. It can be filled with inert gas inside, especially for some items with complex components, which can also be dried quickly.

2. Upgraded version of sound and light alarm environment scanning microcomputer chip, with more powerful data processing function

3. The shortest heating time, compared with the traditional vacuum drying oven, the heating time is reduced by more than 50%, and it will not cause oxidation.

4. Upgraded version of vacuum drying oven with pump, sound and light alarm environment scanning microcomputer chip, with more powerful data processing function

5. LCD large screen backlit liquid crystal display shows the set parameters and measured parameters

6. High-performance constant temperature function to avoid evaporation and drying of samples

7. Consider the safety protection design to achieve triple safety protection for personnel, samples and equipment

8. Safety functions: power failure alarm, sensor failure alarm, over-temperature alarm, independent overheating preventer, independent over-temperature protector (adjustable), independent leakage and over-current tripping protection. Subsidiary functions: automatic shutdown, automatic startup, self-monitoring timer, call recovery, parameter encryption, parameter memory, temperature display correction, RS-232 interface and embedded micro-printer data output, etc. (Auxiliary functions are optional)

9. It has the function of power failure recovery. After the external power supply suddenly loses power and is powered on again, the device can automatically resume operation according to the original setting program

10. The vacuum drying oven with pump adopts a microcomputer P.I.D temperature controller with over-temperature deviation protection and digital display, with a timing function, and the temperature control is accurate and reliable.

11. Using a new type of synthetic silicon sealing strip, it can run at high temperature for a long time, has a long service life and is easy to replace.

12. It can be equipped with a printer or RS485 interface for continuous printing or computer, which can record the change of temperature parameters.

Please read the following precautions before purchasing:

1. In actual work, if the vacuum drying oven with pump is used for corrosive materials such as volatile glue, chemical thinner, acidic, alkaline liquid or solid, please inform the technical department of the unit in time; (vacuum pump, sensor, filter, Liner material, pressure valve, solenoid valve, sealing ring and other accessories for selection)

2. If the vacuum box degasses or deoxidizes liquid or pasty liquid in actual work, it should inform the technical department of the unit before purchasing the equipment (vacuum pumps, sensors, and filters are selected)

3. If the vacuum drying oven with pump is used for long-term drying of materials with a lot of moisture in actual work, the technical department of the unit should be informed before purchasing the equipment; (vacuum pump, sensor, and filter are selected)

4. In the actual work, if the vacuum box is working continuously above 230°C and the pressure is below 100Pa, it should inform the technical department of the unit before purchasing the equipment; (vacuum pump, sensor, filter, liner material, sealing ring, pressure valve, solenoid valve and other accessories for selection)

5. In the actual work, if the material to be processed in the vacuum drying oven with pump is in contact with oil stains and the material is damaged or reacted, the technical department of the unit should be informed before purchasing the equipment; (vacuum pump and other accessories are optional)

| Model | DZF-6090 |

| Power Supply | 220V/50HZ |

| Shell Material | Spray-paint Anti-corrosion |

| Liner Material | 304 Stainless Steel |

| Temp. Range | RT+10~200°C |

| Max. Vacuum Degree | 0.098 Mpa |

| Temp. Stability | ±1.0°C |

| Input Power (W) | 2000 |

| Shelves (Pcs) | 2 |

| Chamber capacity | 90L |

| Optional Configuration | Explosion-proof |

1.Which type of vacuum pump can I choose for the electric drying oven?

The laboratory drying oven produced by our company can be equipped with a rotary vane vacuum pump, a diaphragm pump and a circulating water vacuum pump. Please contact us for specific specifications.

2.Why can't the laboratory vacuum pump be vacuumed?

-The vacuum pump is not the correct model specification.

- Various connecting pipes (heads) are loose, and the inner diameter is too fine

- Vacuum gauge damage

-The drying box door is not closed

- Vacuum drying oven door seal rubber aging loses elasticity

-The bleed valve and vacuum valve are connected incorrectly

3.How will you deliver these goods?

It will be decided based on your quantity. Usually we will choose international express, air and sea.

4.Can I monitor the temperature inside the instrument in real time?

Of course, you can observe the real-time temperature through the LED display for your convenience.