-

WhatsApp

-

Email

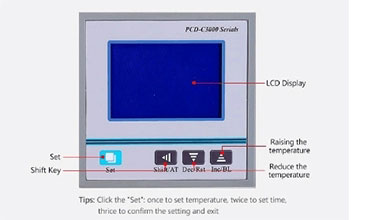

The manufacturer of the laboratory drying oven uses a PID temperature controller with a temperature error of ±1 °C, which allows precise temperature control.With a timing digital microcomputer temperature controller to ensure the quality of the material being dried.

Features

- Timing digital microcomputer temperature controller.

- Cuboid chamber,achieve the maximum of effective volume.

- Observe the object in the working chamber at a glance.

- Adjust the tightness of the door is closed, ensure the high vacuum degree in the cabinet.

- The working chamber is made of stainless steel plate ensures durability.

- We can observe indoor objects through toughened and bullet-proof glass doors and can fill the workroom with inert gas.

- The studio is made of stainless steel plate(or wire-drawing sheet), ensure durability.

Detail

|

- Built in Chip(Chip Temperature Control):

Intelligence Timing Accurate Temperature control

|

|

|

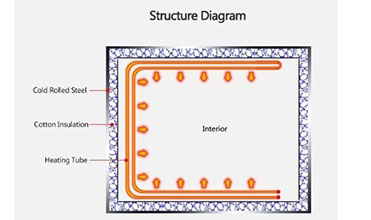

- Cold Rolled Steel Sheet:

Cold rolled steel sheet makes the chamber not deform in the vacuum condition and extends service life. The cotton insulation not only prevents heat loss inside, but also ensures the shell is not hot

|

|

- Heating Tube:

Heating around the inwall, more uniform, no overshoot, nonflammable, anti-explosion and more dafe stainless steel material, non deformation and long service life

|

|

|

- Microcomputer Temperature Control: Temperature controller with timer fuction to ensure precise and reliable temperature control Built in chip, precise temperature control(Accuracy±0.1℃ easy operation reliable performance display direactly and easy operation |

|

|

|

| Switch | Double Layer Explosion-proof Glass | Silicon Rubber Strip |

For the perfect use of the entire vacuum drying oven system, you may need the following equipment

- Circulating water type multi-function vacuum pump

- Diaphragm vacuum pump

- Rotary vane vacuum pump

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | DZF-6050 | ||

| Overal Size(W×D×H) | 730*560*550mm | ||

| Chamber size(W×D×H) | 415*370*345mm | ||

| Volume | 52L | ||

| Temperature | Range | Ambient+10°C ~ 250°C /Ambient+5°C ~ 200°C | |

| Resolution | 0.1°C | ||

| Fluctuation | ±1°C | ||

| controller | PID controller | ||

| Vacuum Degree | 133Pa | ||

| Safety device |

Electric leakage breaker (ELB), overheating protection system |

||

| Material | interior | Stainless steel plate | |

| exterior | Steel plate with powder coated finish | ||

| Net Weight /Gross Weight | 80 /85kg | ||

1.How is your oven heated?

There are many heating electric pipes surround the chamber inside, to keep the high temperature.

2.Can I monitor the temperature inside the instrument in real time?

Of course, you can observe the real-time temperature through the LED display for your convenience.

3.What is the temperature range of the DZF series vacuum drying oven?

Temperature setting range: -RT+10~200.0°C;

Basic error of temperature measurement: < 0.3%;

4.What is the time setting for the drying oven?

Time setting range: 0 to 9999 minutes (hours);

Timing error: < 1%;