-

WhatsApp

-

Email

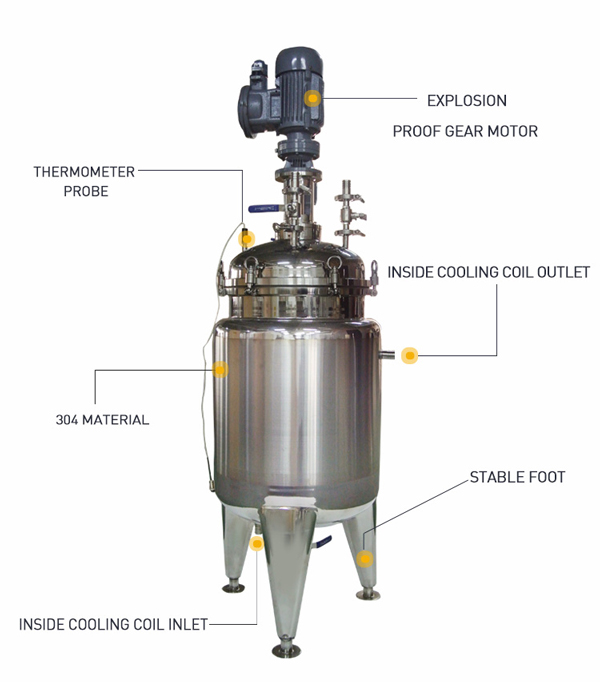

The stainless steel jacketed reactor is generally divided into three major components: the kettle body, the jacket, and the stirring system. In addition, the kettle cover (head), jacket or coil (heating and cooling cycle), agitator (anchor type, paddle type, Turbine type, etc.), transmission device (motor reducer), shaft seal device (mechanical seal), heat preservation medium, support (legs, platform) and other components. Most of the main equipment of the reactor is made of SUS304/316L stainless steel. The inner cylinder wall adopts mechanical polishing or electrolytic mirror polishing, the outer cylinder wall adopts 304 fully welded structure for heat preservation, and the outer surface adopts mirror or matte treatment; the external connection of the cylinder adopts sanitary quick-opening joints, which are safe and hygienic without dead ends; Temperature monitoring device, temperature measuring hole, CIP automatic rotating spray washing ball quick-opening material inlet and outlet, temperature sensor, sight mirror spotlight, liquid level gauge and other devices are convenient for manual operation, simple and reliable.

The composition and structure of stainless steel jacketed reactor:

The stainless steel jacketed reaction kettle is composed of kettle body, kettle cover, jacket, agitator, transmission device, shaft seal device, support and so on. It can also be referred to simply as consisting of three parts: tank body, jacket and stirring system.

1. Materials of stainless steel jacketed reactor:

Stainless steel jacketed reactors are generally made of carbon-manganese steel, stainless steel, zirconium, nickel-based (Hastelloy, Monel) alloys and other composite materials; parts in contact with materials are made of high-quality stainless steel such as 304 or 316L, which meets GMP standards.

2. Accessories for stainless steel jacketed reactor:

· Multiple frame stirring is used to ensure that the materials are evenly blended in a short time; at the same time, frame, anchor, paddle, etc. can be selected according to needs

· The seal adopts a sanitary mechanical seal, which can ensure the pressure in the tank and prevent unnecessary pollution caused by leakage of the material in the tank;

· The interface adopts the ISO standard quick-installation clamp type, which is convenient and hygienic;

· Sterile respirator, CIP cleaning nozzle, sight glass, flange, sanitary quick opening manhole, etc.

3. Surface treatment of stainless steel jacketed reactor:

· The inner surface is mirror-polished to ensure no hygienic dead corners. The fully enclosed design ensures that the material is always in a sterile state. The outer surface can be sandblasted, frosted, or cold-rolled and matte.

· Heating and cooling: steam, electric heating and heat conduction oil can be selected as heating methods to meet the technological needs of different working environments such as acid resistance, alkali resistance, high temperature resistance, abrasion resistance and corrosion resistance.

· Stainless steel jacketed reactors are widely used in petroleum, chemical, rubber, pesticides, dyes, medicines, food, pressure vessels used to complete vulcanization, hydrogenation, alkylation, polymerization, condensation and other processes, such as reactors, reactors, Decomposition pot, polymerization kettle, etc.

Stainless steel jacketed reactor use and maintenance:

1. It should be operated and used strictly in accordance with the working pressure and working temperature calibrated on the operating instructions to avoid danger;

2. The agitator is the main part of the reactor, and it is necessary to strictly abide by the regulations on cooling and oiling in the product instruction manual, and do a good job in the maintenance and maintenance of the equipment;

3. The reactor reducer is installed vertically, requiring good lubrication, no vibration, no leakage, and long-term stable operation;

4. When using all valves, the valve stem should be turned slowly to press the sealing surface to achieve the sealing effect. It is not easy to use too much force when closing, so as not to damage the sealing surface:

5. Regularly check the corrosion of the reactor shell and take appropriate measures to repair it;

The stainless steel jacketed reactor has the characteristics of no leakage, fully enclosed, corrosion resistance, and energy saving. Due to its non-contact transmission of torque, the static seal replaces the dynamic seal, which solves the problem that other shaft seals cannot overcome the leakage. The entire medium and stirring parts operate in a sterile and hygienic state. It is suitable for pharmaceuticals, fine chemicals, cosmetics, biological engineering, etc. The ideal replacement product for the industry. The stainless steel jacketed reactor is mainly composed of three parts: the tank body, the jacket, and the stirring system. It is suitable for mechanical stirring of flammable, explosive, toxic, and odorous materials and other materials for dissolution and sterilization under a certain pressure. The fermentation process requires Equipment that operates at constant pressure for more than 24 hours for a long time. It is more suitable for the equipment that does not allow any trace leakage and pollution in the production process of bioengineering. The stainless steel jacketed reactor can be made of carbon steel, stainless steel and other materials according to the user's process requirements for the product, and heating and cooling devices can be set to meet different process and production needs. The heating type has jacket electric heating and coil heating. The stainless steel jacket reactor has reasonable structure design, advanced technology, durability, and has the characteristics of simple operation and convenient use. It is an ideal chemical industry with less investment, quick production and high profit equipment.

1. Composition of stainless steel reactor.

-Material of stainless steel reactor◆ The parts in contact with the material are made of high-quality stainless steel such as 304 or 316L, which conform to the GMP standard.

-Accessories for stainless steel chemical reactors

◆ Multi-frame mixing is used to ensure that the materials are evenly mixed in a short period of time; at the same time, frame, anchor, and slurry types can be selected according to needs.

◆ The seal adopts a sanitary mechanical seal, which can ensure the pressure in the tank and prevent unnecessary pollution caused by leakage of materials in the tank;

◆ The interface adopts ISO standard quick-release clamp type, which is convenient and hygienic;

◆ Aseptic respirator, CIP cleaning nozzle, sight glass, flange, sanitary quick-opening manhole, etc.

-Surface treatment of stainless steel batch reactor

◆ The inner surface is mirror-polished to ensure no sanitary dead corners. The fully closed design ensures that the material is always in a sterile state. The outer surface can be sandblasted, matte, and cold-rolled primary color matte.