-

WhatsApp

-

Email

Spray dryer machine is a critical equipment in the chemical, pharmaceutical, food, and beverage industries. It is used to produce high-quality powders, granules, and other dry forms of liquid products, such as milk, coffee, and pharmaceutical drugs. The machine utilizes the principle of evaporation, which involves the conversion of a liquid material into a solid form by removing its moisture content. In this article, we will explore the working principle, components, types, applications, advantages, and disadvantages of a spray dryer machine.

Spray dryer machine working principle

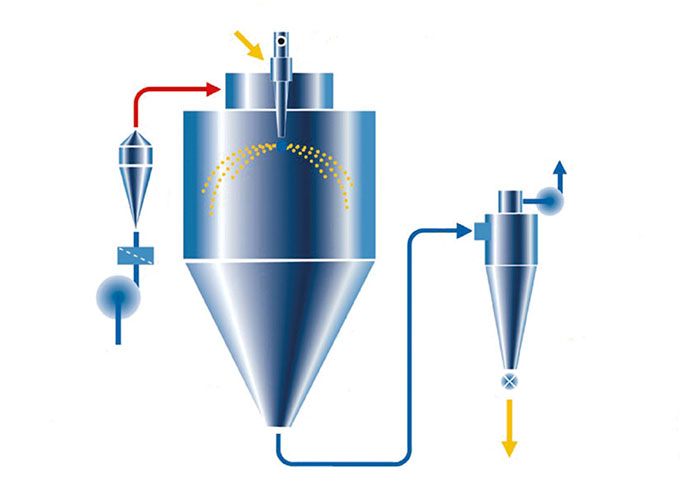

The spray dryer machine works by atomizing a liquid feedstock into fine droplets and introducing them into a hot air chamber. The hot air heats up the droplets, causing the moisture to evaporate rapidly. As a result, the droplets transform into dry particles, which are collected at the bottom of the drying chamber. The drying chamber has an exhaust system that removes the evaporated moisture and other volatile substances. The final product is a dry, free-flowing powder or granule.

Components of spray dryer machine

The spray dryer machine has four main components: a liquid atomization system, a drying chamber, an air heating system, and a product collection system. The liquid atomization system consists of a high-pressure nozzle or disk that produces a fine mist of liquid droplets. The drying chamber is a cylindrical vessel that provides a hot air stream to evaporate the moisture from the droplets. The air heating system comprises a heater or a furnace that heats up the air before it enters the drying chamber. The product collection system is a hopper or a cyclone separator that collects the dry particles and separates them from the exhaust air.

Types of spray dryer machine

Spray dryer machines come in different types, In terms of capacity, it can be divided into lab spray dryer and large spray dryer, depending on their design and application. The three most common types are single-stage, two-stage, and closed-loop spray dryer machines. Single-stage spray dryer machines have one drying chamber and one exhaust system. They are suitable for drying heat-sensitive and non-sticky materials. Two-stage spray dryer machines have two drying chambers and two exhaust systems. They are suitable for drying high-viscosity and high-moisture materials. Closed-loop spray dryer machines are designed for drying toxic and hazardous materials. They have a closed-loop system that recirculates the exhaust air, preventing the release of harmful substances into the environment.

Applications of spray dryer machine

Spray dryer machines are used in a wide range of industries, including the chemical, pharmaceutical, food, and beverage industries. In the chemical industry, they are used to produce catalysts, pigments, and resins. In the pharmaceutical industry, they are used to produce antibiotics, vitamins, and inhalable powders. In the food and beverage industry, they are used to produce milk powders, coffee powders, and fruit juice powders. They are also used in the environmental and energy industries to produce catalysts and fuel additives.

Advantages of spray dryer machine

Spray dryer machines offer several advantages over other drying methods, such as freeze drying and drum drying. Firstly, they can produce a large quantity of dry product in a short amount of time, making them suitable for industrial-scale production. Secondly, they can produce a fine powder with a narrow particle size distribution, making them suitable for applications that require consistent product quality. Thirdly, they can preserve the product's original flavor and aroma, making them suitable for producing food and beverage powders. Lastly, they can be customized to meet specific product and process requirements, making them versatile and flexible.

Spray dryer machines also have some disadvantages, such as high energy consumption, high capital and maintenance costs, and limited application to certain materials. Firstly, they require a significant amount of energy to heat up the air and maintain the drying chamber's temperature. Secondly, they require a considerable initial investment, and their maintenance costs can be high due to the complexity of the equipment. Thirdly, they may not be suitable for some materials, such as those that are heat-sensitive or those that contain volatile compounds that can be lost during the drying process.

Spray dryer machines are a vital piece of equipment in many industries that require the production of dry powders and granules. They work by atomizing liquid feedstock into fine droplets and then evaporating the moisture through the hot air stream. They have several advantages, such as high production capacity, consistent product quality, and versatility in customization, but also some disadvantages, such as high energy consumption and high capital and maintenance costs. Nonetheless, their benefits far outweigh their limitations, making them an indispensable tool for modern industrial manufacturing. As technology continues to advance, it is expected that spray dryer machines will become even more efficient and versatile, opening up new possibilities for the production of innovative products in a wide range of industries.