-

WhatsApp

-

Email

The small spray dryer has a highly intelligent full-automatic control system, which is suitable for research and development and production of trace particle powders in universities, research institutes and laboratories of food, biological, beverage, chemical, material, pharmaceutical and other enterprises.

Features

- Special for lab research, Min 20-30ml liquid to finish one test

- All borosilicate glass for easy visual monitoring of process status.

- Spray chamber, cyclone separator, receiving tank are all made of Borosilicate glass which can resist strong acid/alkali, high temperature. It can work in a no-pollution and stable environment.

- Easy to clean and very simple to assemble and break down.

- The air compressor is oil-free and does not contaminate the compressed air. The sound is below 50db.

- inlet/outlet temperature is accurate controlled by PID

- Use the touch screen to display operation, control temperature, air flow, air pressure, pump speed and deblocking frequency.

- Feeding with RS2559605 rotary pump with adjustable capacity.

- The automatic de-blocking device prevents the nozzle from becoming blocked and variably controlled.

Detail

We provide quality accessory accessories for spray dryers:

-High-quality borosilicate heat-resistant glass drying room.

-High quality borosilicate heat resistant glass cyclone separator.

-High-quality borosilicate heat-resistant glass sample collection bottle.

-High-quality borosilicate heat-resistant glass sample collection tube, feeding silicone tube, clip.

-High quality borosilicate heat resistant glass cyclone separator.

-High-quality borosilicate heat-resistant glass sample collection bottle.

-High-quality borosilicate heat-resistant glass sample collection tube, feeding silicone tube, clip.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. What system control is used in the laboratory spray dryer?

The spray dryer adopts the double control mode of automatic control and manual control. The whole experiment process uses LCD large LCD touch screen dynamic display (animation) air inlet temperature/air outlet temperature / peristaltic pump speed/air volume/needle frequency.Fully automatic control: After one-button start-up, after setting the spray process parameters, the temperature reaches the predetermined temperature and starts up automatically. The running animation is displayed on the touch screen, and the running process is clearly displayed; when the machine is shut down, just press the stop button and the machine automatically shuts down safely.

Manual control: If the process parameters need to be adjusted during the experiment, it is convenient to switch to the manual state. The color touch screen is dynamically displayed (animation) throughout the experiment.

Shutdown protection function: After the instrument is finished, the working state of the fan should be kept, so that the glass is partially cooled. The machine is set by an intelligent program. When the inlet temperature is lower than 50 degrees, the fan is automatically turned off, no manual shutdown of the fan is required; The heating element is over-burned due to misoperation (forced shutdown of the fan).

2. Which industries is the spray dryer machine suitable for?

It is mainly used in research and development and production of micro-particle powders in universities, research institutes and food, biological, beverage, chemical, materials, pharmaceutical and other enterprise laboratories. It has broad-spectrum applicability to all solutions such as emulsions and suspensions and is suitable for heat. The drying of sensitive substances such as biological products, biological pesticides, enzyme preparations, etc., because the materials ejected are only subjected to high temperature when sprayed into mist-sized particles, so they are only heated instantaneously, and the active materials can be maintained after drying. Its active ingredients are not destroyed.

3. What are the characteristics of the laboratory small spray dryer?

The laboratory spray dryer has a built-in oil-free air compressor. The air compressor is equipped with a stainless steel gas storage tank. The diameter of the powder spray is normally distributed, the fluidity is good, and the noise is very low.The atomization structure of the two-fluid spray, the whole machine is made of high-quality stainless steel material, never rust and corrosion, high-quality high borosilicate heat-resistant drying chamber, high-quality high borosilicate heat-resistant cyclone separator, high-quality high borosilicate heat-resistant sample collection bottle The high-quality borosilicate heat-resistant sample collection tube enables the drying process to be carried out in a non-polluting environment; and the entire spray drying experiment process is transparent and intuitive, and all the original glass parts are easily removable.

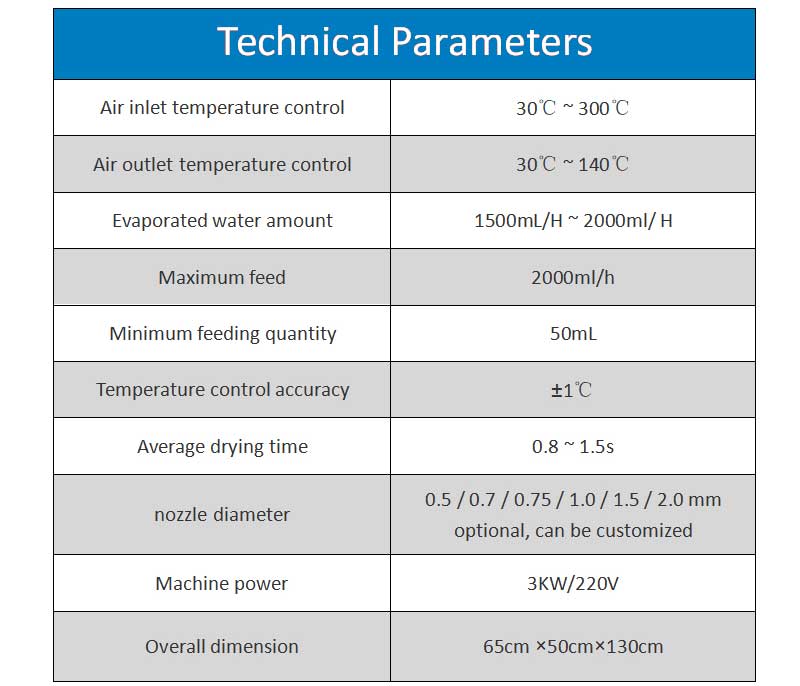

In order to meet the requirements of the user to adjust various parameters in the experimental range, the real-time regulation PID constant temperature control technology is adopted in the design of the drying temperature control, so that the temperature control in the full temperature zone is accurate, and the heating temperature control precision is ±1 °C.