-

WhatsApp

-

Email

In the realm of laboratory equipment for chemical and biological pharmaceutical processes, the rotary evaporator has emerged as a pivotal tool, particularly in the extraction of aromatic compounds. Aromatic compounds, known for their distinct odors and diverse applications, are essential components in industries ranging from perfumery to pharmaceuticals. The rotary evaporator extraction technique has proven to be indispensable in isolating and concentrating these valuable aromatic compounds efficiently and effectively. In this article, we delve into the world of rotary evaporator extraction, exploring its principles, applications, and advantages.

Understanding Rotary Evaporator Extraction

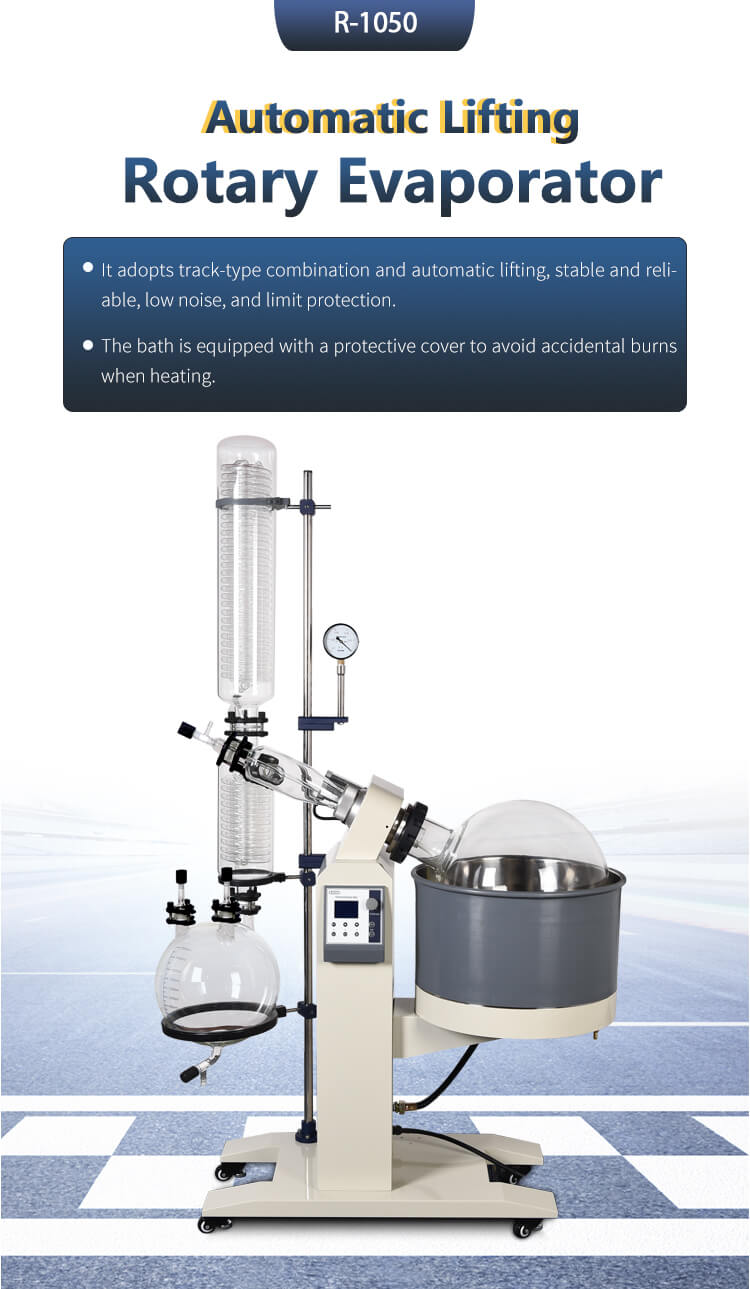

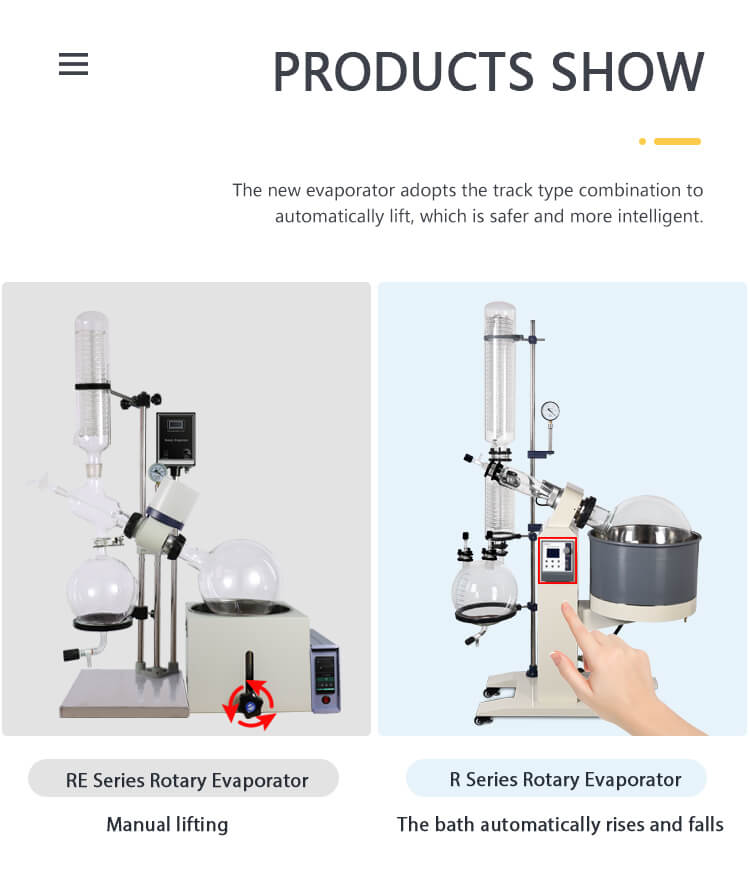

The rotary evaporator, also known as a rotovap, is a sophisticated apparatus used in laboratories for separating solvents from solutions through evaporation. This technique is particularly adept at handling heat-sensitive materials like aromatic compounds. The process involves subjecting a solution containing the desired aromatic compounds to reduced pressure and controlled temperature, causing the solvent to evaporate while leaving behind the concentrated aromatic extract.

Principles of Aromatic Compound Extraction

Aromatic compounds, due to their unique chemical structures, require a method that preserves their delicate nature during extraction. The rotary evaporator's principle of operation aligns well with this requirement. By lowering the boiling point of the solvent through reduced pressure, the process minimizes the chances of thermal degradation of aromatic compounds. This gentle evaporation process ensures that the aromatic compounds retain their integrity and potency.

Applications of Rotary Evaporator Extraction for Aromatic Compounds

The applications of rotary evaporator extraction in dealing with aromatic compounds are wide-ranging. From the production of essential oils with distinct fragrances to the isolation of medicinal compounds for pharmaceutical research, the versatility of this technique is evident. Perfumery industries utilize rotary evaporators to capture the essence of flowers and plants, preserving their aromatic profiles for use in perfumes and cosmetics.

Advantages of Rotary Evaporator Extraction

The utilization of rotary evaporator extraction for aromatic compounds offers several key advantages. Firstly, the controlled evaporation process minimizes the risk of degradation, ensuring the quality and purity of the extracted compounds. Additionally, the ability to recover and reuse the solvent presents economic benefits. The technique's scalability makes it suitable for both small-scale laboratory research and large-scale industrial production.

Factors Influencing Extraction Efficiency

Several factors play a crucial role in determining the efficiency of rotary evaporator extraction for aromatic compounds. Temperature control is paramount, as different aromatic compounds have distinct boiling points. Maintaining the right balance between reduced pressure and controlled temperature ensures optimal evaporation while avoiding excessive heat that could damage the compounds.

Optimization of Extraction Parameters

Achieving the best results in rotary evaporator extraction requires a comprehensive understanding of the process parameters. Fine-tuning variables such as rotation speed, bath temperature, and vacuum level can significantly impact the yield and quality of the aromatic compounds. Moreover, the choice of solvent and the concentration of the initial solution are critical factors that demand meticulous consideration.

Safety Considerations in Rotary Evaporator Extraction

While rotary evaporator extraction is a powerful technique, it is not without its safety considerations. The process involves working with potentially volatile and flammable solvents. Proper ventilation, adherence to safety protocols, and the use of protective equipment are imperative to mitigate any risks associated with the extraction process.

Conclusion

In the dynamic landscape of laboratory equipment and techniques, rotary evaporator extraction stands out as a cornerstone method for obtaining aromatic compounds of the highest quality. Its gentle yet efficient process, coupled with its wide-ranging applications, has solidified its place in industries spanning from perfumery to pharmaceuticals. By understanding the principles, advantages, and optimization strategies of rotary evaporator extraction, researchers and manufacturers can harness the power of this technique to unlock the aromatic wonders found in nature's compounds.