-

WhatsApp

-

Email

Vacuum ovens utilize heating radiation to warmth, no wind heating treatment will ensure the sleek surface of samples. The warmth therapy like an oven and applies vacuum approach to make a vacuum-sealed chamber. Adopting the aviation technology bushing therapy process, the lifetime of the exhaust valve piece reaches 10 billion times. The touch display screen kind commonplace with a USB interface, which may record the change standing of the temperature parameters. Lab vacuum drying oven with No Oxidation are very versatile pieces of kit with functions in laboratory analysis, engineering, and trade. A vacuum drying oven quotes is most frequently used for delicate drying processes, corresponding to drying tiny elements or removing flammable solvents. The low stress surroundings also minimizes oxidation throughout drying.

Lab vacuum drying oven:

Vacuum ovens can function at excessive temperatures from round 200 to 250 levels Celsius. In a vacuum drying oven quotes, the thermal processes happen in an hermetic chamber where a desired vacuum stage is about using an external vacuum pump. With industrial vacuum drying oven factory, entire functions can happen beneath vacuum or in a controlled atmosphere via the introduction of an inert gas. Vacuum ovens may help within the prevention of surface reactions , decontaminating samples as nicely as for dashing up the out gassing process.

During the vacuum drying oven quotes process, the floor temperatures of the object being dried want to stay near-constant. If the temps go up, this will damage the item, if they get too low, condensate types, permitting the newly converted water vapour to coalesce into liquid. Drying ovens are suitable for supplies which are inclined to damage when heated high temperatures. Vacuum ovens are oven designed to function at comparatively low temperatures with an exhaust port that vents moisture away from the vegetation being dried. The oven also creates a low-pressure space inside, which reduces the temperature at which liquid water transforms to a fuel. Heating component is located within the inside partitions of the field. BHO vacuum oven ' This sort of oven is used primarily inside the cannabis trade to take away the butane hash oils. Lab vacuum drying oven with No Oxidation for BHO are additionally referred to as vacuum purge ovens. In the case of a low-pressure ambiance, the boiling temperature of water reduces from a hundred C down. The larger the warmth, the more the bonds open and the more liquid water can turn into water vapour.

Vacuum drying oven quotes:

To keep vacuum states within the chamber, can fll working chamber with inert gasoline (infation strain ɗ 0.1 MPa). 3.Tempered, bullet-proof double glass door ensure the security of operator and clear remark of the chamber. The warnings are meant to help california shoppers make informed choices about their exposures to those chemical compounds from the products they use. The California Office of Environmental Health Hazard Assessment administers the Proposition 65 program and publishes the listed chemical compounds, which incorporates more that 850 chemicals.

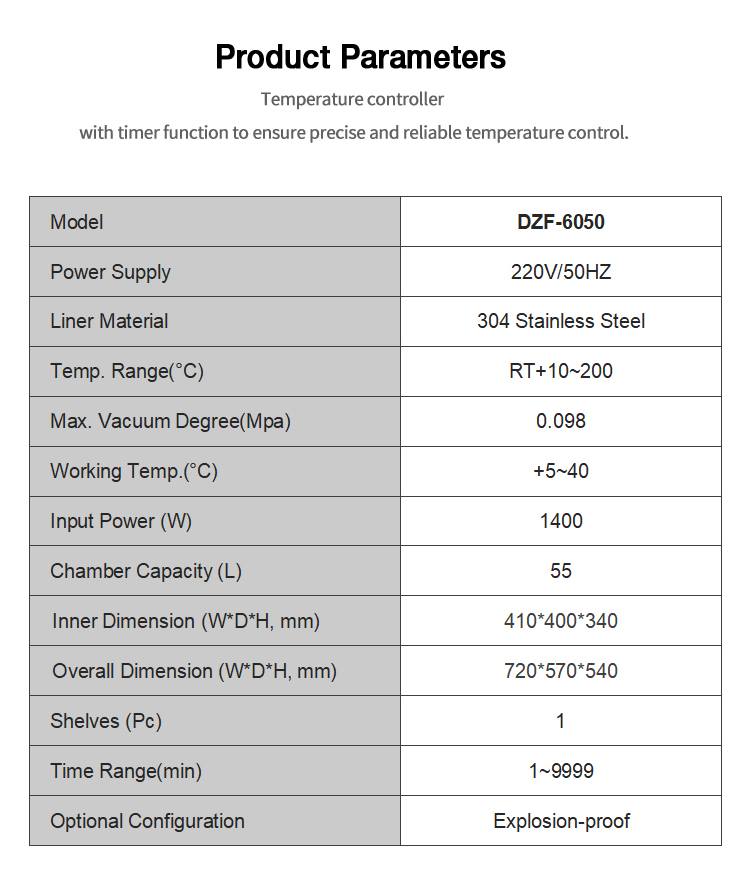

As the air moves across the item, the item heats up from the power of the water transferring from a liquid to a gaseous state. This slows down the drying because the temperature distinction between the air and the surface shrinks. And we manufacture business greatest industrial vacuum drying oven factory designed to make your corporation more profitable. Plus, to ensure your drying oven matches your calls for and lab situations. You can select your drying oven model according to its inner capacity, operating temperature and energy supply. Aluminum shelf stamped by particular techniques, capable of conduct warmth fast and resist excessive temperature oxidation, providing maximum discount of heat loss. High performance MCU-based temperature controller with advanced PID algorithm to maintain temperature uniformity (+/- 1°F) from low temperature to 480°F (250°C). The vacuum Control Module makes it potential for a strain to extend. The oven should have the power to assist computerized will increase and reduces anxiety. This versatility contributes to a faster, non-aggressive setpoint response interval, letting further evaluations collectively utilizing varying climatic issues.

At lower pressures, it is simpler for the slower shifting particles to escape without collisions that create waste heat. Less waste warmth retains the response occurring at decrease vitality and so forth. As stress increases, warmth will increase and the surplus power of the atoms gets transformed into faster motion. You might have heard of the ‘excited’ particles in this context. Particles transferring quicker collide extra typically and with more drive, creating waste heat. At a high sufficient stress, most substances compact, becoming defacto solids. The internal stress of the solar is such that it converts the gas into superheated plasma, for example. Humid air is already saturated with water vapour, so it has much less pull to assemble extra. The digital controller of PID single chip microprocessor has the functions of timing and over temperature safety. We can observe indoor objects via the solid bulletproof glass door and fill the studio with inert gasoline. The maximum efficient quantity of the cuboid cavity, microcomputer temperature controller, accurate and dependable temperature management. We can observe indoor objects by way of toughened and bullet-proof glass door, and can fill the workroom with inert fuel.

Industrial vacuum drying oven factory:

Drying gadgets in a vacuum oven reduces oxidation, gently dries delicate merchandise, and reduces your danger of being exposed to dangerous chemical compounds. To purchase a higher-excellent vacuum drying oven quotes test chamber, some features you should seek for, in addition to appropriate, programmable controllers and in addition a keyboard port. Vacuum toaster ovens can be obtainable with technical features like mold restoration or residual petrol investigation to cease additional drying. For drying rancid solvents, discover a safe vacuum drying oven that was permitted for these explicit products. Lab vacuum drying oven with No Oxidation are appropriate for off-gassing solvents in hashish manufacturing. Using a vacuum drying oven to purge solvents is cost-effective because it removes steps from your extraction course of.

Once cleaning, the vacuum cleansing procedure is used correctly, leaving no leftover material in the slightest. Second, when working with organic or bioactive substances, a precise stage of management is needed to copy samples. Other drying methods leave extra open variables than vacuum drying which controls the pressure, temperature, and airflow, all of whichlimit contamination and error margins. Case in level, a vacuum oven finds use where drying is required but heating is out of the question. Likewise for conditions where friction from transferring air will damage a pattern or a course of. Yamato drying industrial vacuum drying oven factory are among the most well-engineered in the world.