-

WhatsApp

-

Email

Spray dryers play a pivotal role in various industries, including the chemical, pharmaceutical, and food sectors. They are essential for converting liquid or slurry substances into dried powders or granules. In this article, we'll delve into the fascinating world of spray dryer machine, exploring their working principles, components, and applications.

The Basics of Spray Drying

Spray drying is a widely-used industrial process that involves the conversion of a liquid feed into a dried powder or granular form. The primary objective is to remove moisture content while preserving the product's properties. Here's how a spray dryer achieves this:

Atomization of Liquid Feed

The process begins with the liquid feed being atomized into tiny droplets. This is typically accomplished by using a high-pressure nozzle or rotary atomizer. The goal is to create a large surface area for efficient drying.

Hot Air Introduction

Simultaneously, hot air is introduced into the drying chamber. This hot air serves two crucial functions: it evaporates the moisture from the droplets, and it carries the moisture-laden air out of the chamber.

Drying and Formation of Powder

As the atomized droplets move through the drying chamber, they lose moisture and transform into solid particles. These particles are collected at the bottom of the chamber as dried powder or granules.

Components of a Spray Dryer

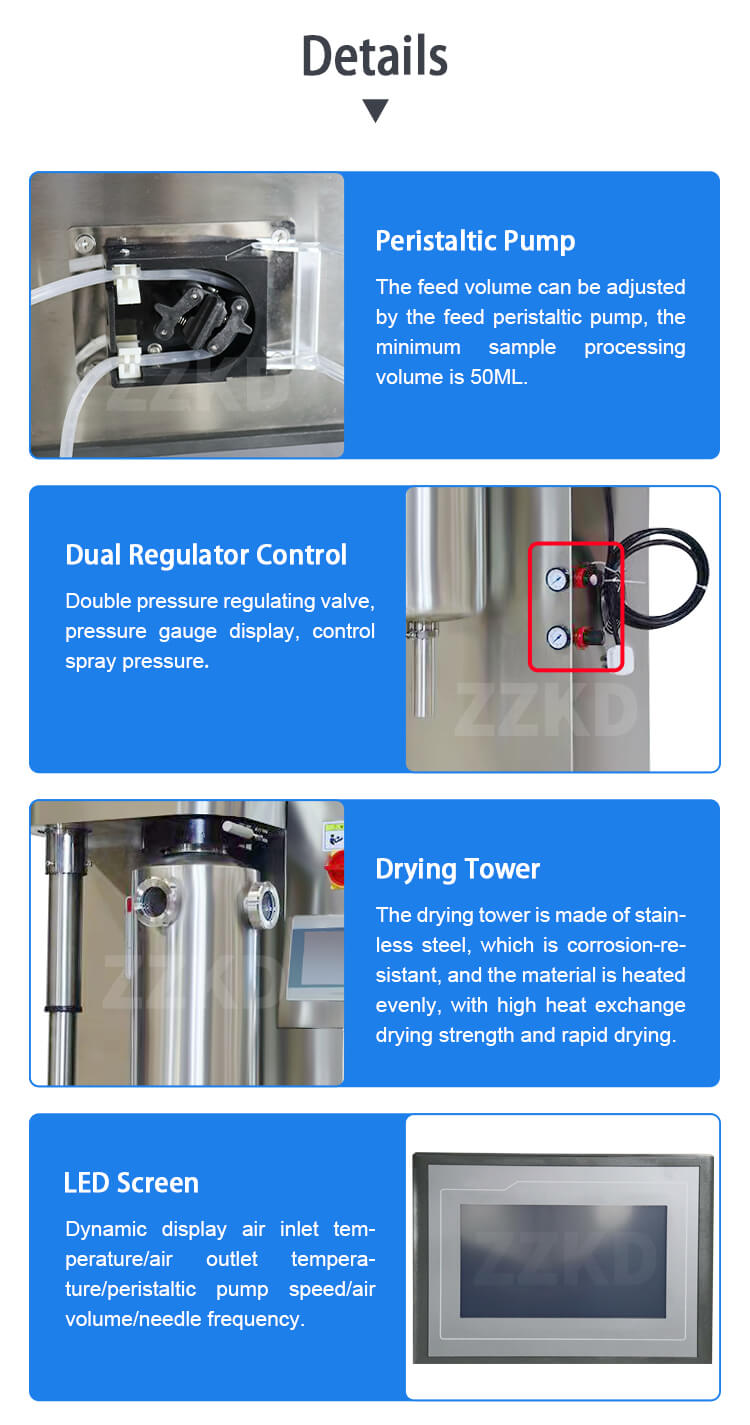

Understanding the key components of a spray dryer is essential to grasp its functioning. A typical spray dryer consists of several crucial elements:

Drying Chamber

The heart of the spray dryer is the drying chamber, where atomization, drying, and powder formation occur. The design of this chamber is critical to achieving desired drying outcomes.

Atomization System

The atomization system, which includes nozzles or atomizer wheels, is responsible for breaking down the liquid feed into droplets. The type of atomization method used can impact the quality of the final product.

Hot Air Source

A reliable source of hot air, often generated by heaters or gas burners, is necessary to facilitate the drying process. The temperature and humidity of the hot air can be adjusted to suit the specific product requirements.

The Role of Process Control

Achieving consistent and high-quality results in spray drying relies on precise process control. Here's how it works:

Monitoring and Regulation

Sophisticated sensors continuously monitor parameters such as inlet air temperature, outlet air temperature, and feed flow rate. These measurements are used to regulate the drying process in real-time.

Feedback Loops

Feedback loops are integrated into the control system to make immediate adjustments based on the monitored data. This ensures that the drying conditions remain optimal throughout the process.

Quality Assurance

Process control not only enhances efficiency but also helps maintain product quality and uniformity. It minimizes variations in particle size, moisture content, and other critical attributes.

Applications of Spray Dryers

Spray drying finds extensive use in various industries due to its versatility. Here are some notable applications:

Food Industry

In the food industry, spray drying is used to create instant coffee, powdered milk, and flavorings. It helps preserve the taste and aroma of the original product.

Pharmaceutical Industry

Pharmaceutical companies use spray dryers to produce medications in powdered form, making them easier to package and administer.

Chemical Industry

The chemical sector utilizes spray drying for the production of catalysts, pigments, and various chemical compounds. The process enables precise control over particle size and composition.

Advantages and Limitations

While spray dryers offer numerous benefits, they also come with certain limitations:

Advantages

- Rapid drying process

- Preservation of product properties

- Enhanced shelf life

- Reduced transportation costs for powders

Limitations

- High energy consumption

- Challenges with heat-sensitive materials

- Potential for agglomeration in the final product

- Equipment costs and maintenance requirements

Future Trends and Innovations

The field of spray drying continues to evolve, driven by technological advancements and industry demands. Some future trends and innovations include:

Energy Efficiency

Efforts are being made to develop more energy-efficient spray drying processes through improved heat recovery and insulation.

Sustainable Practices

Manufacturers are exploring eco-friendly alternatives to reduce environmental impact, such as using renewable energy sources and optimizing waste management.

Nanoparticle Production

Spray drying is being adapted for the production of nanoparticles, opening up new possibilities in drug delivery and advanced materials.

In conclusion, spray drying is a versatile and essential process that plays a vital role in various industries. Understanding how spray dryers work and their components is crucial for achieving efficient and consistent drying results, ultimately impacting the quality and cost-effectiveness of the final product. As technology continues to advance, we can expect further innovations that will enhance the efficiency and sustainability of spray drying processes across industries.