-

WhatsApp

-

Email

Introduction to Explosion Proof Rotary Evaporators

In laboratories worldwide, managing volatile substances safely and efficiently is a constant challenge. The Explosion Proof rotary evaporator emerges as a solution, ingeniously designed to handle sensitive chemical processes with utmost safety. This device, an advanced version of the standard laboratory rotary evaporator, integrates Explosion Proof features, making it indispensable for labs dealing with flammable substances.

Initially, rotary evaporators were simply used for solvent removal. However, with the advent of Explosion Proof technology, they have become vital in preventing lab accidents. These enhanced evaporators are equipped with features that prevent the ignition of explosive atmospheres, a common hazard when working with volatile solvents like ethanol or acetone.

The Need for Explosion Proof Equipment in Laboratories

Laboratories are often fraught with hazards, particularly when working with volatile organic compounds (VOCs). The introduction of Explosion Proof Rotary Evaporators has been a game-changer in such settings. These devices are specifically designed to contain and prevent explosions, a critical safety measure when dealing with flammable gases, vapors, or liquids.

For example, during the distillation of ethanol, standard equipment might spark, igniting vapors. Explosion Proof models, however, are built to prevent such incidents. They achieve this through specialized construction materials and design features that isolate and contain any potential ignition sources, making them a necessary investment for any lab handling combustible materials.

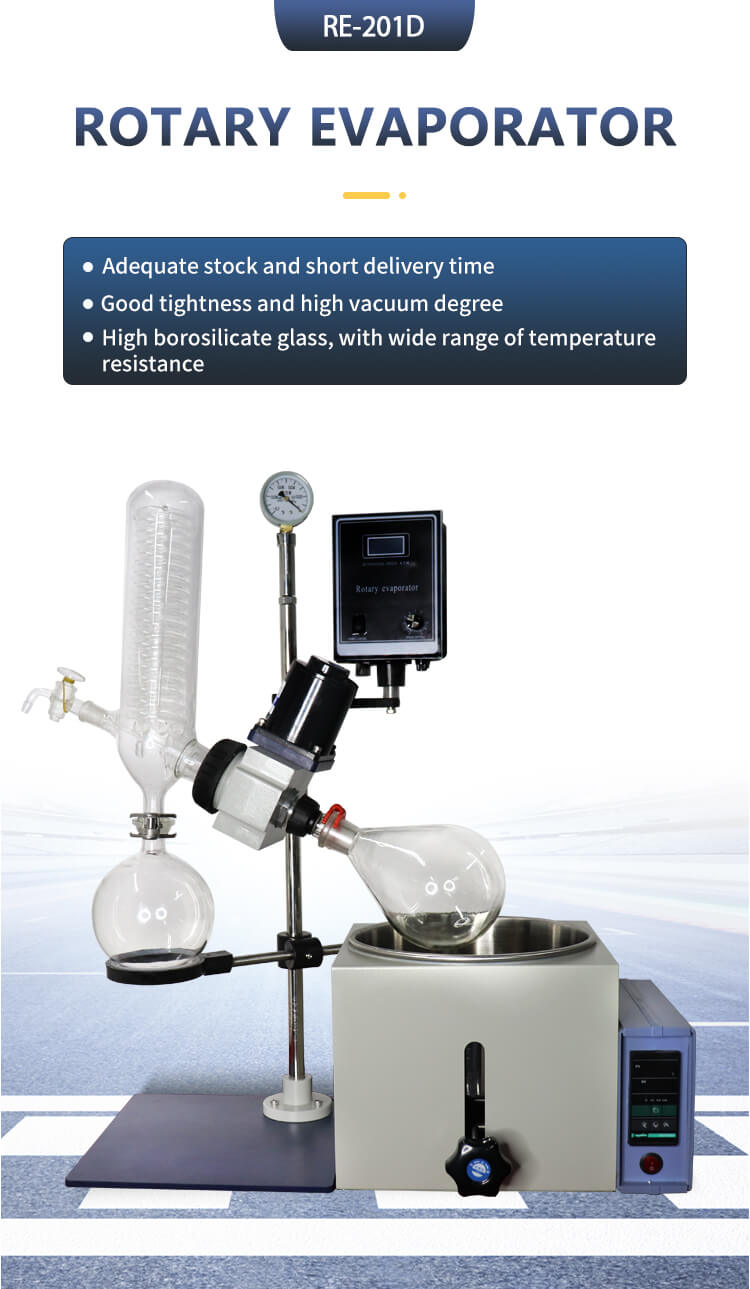

Key Features of Explosion Proof Rotary Evaporators

ZZKD Machinery and Instrument Equipment Co., Ltd., a leader in lab equipment, manufactures top-tier Explosion Proof Rotary Evaporators. These devices boast several key features, such as advanced cooling systems for efficient condensation of vapors, digital temperature controls for precise heating, and inert gas purging mechanisms to replace flammable atmospheres with non-reactive gases.

Additionally, these evaporators are constructed with flameproof motors and electrical components, ensuring that no spark can escape the equipment. The glass parts are often coated with a safety film to contain glass shards in case of an implosion, adding an extra layer of safety to the process.

Understanding the Technology Behind Explosion Proof Design

The technology behind Explosion Proof design is intricate and essential for safety. The primary aim is to remove any ignition sources and contain potential explosions within the apparatus. This is achieved through several methods, such as using non-sparking materials like brass or stainless steel for all moving parts and enclosing electrical components in flameproof enclosures.

The wiring and controls of these evaporators are also designed to minimize electrical hazards. They often feature intrinsically safe circuits, where the energy levels are kept too low to cause ignition, ensuring that even in the event of a fault, the risk of sparking is negligible.

Applications in Various Industries

Beyond academic research, Explosion Proof Rotary Evaporators are extensively used in industries like pharmaceuticals, petrochemicals, and perfumery. In these sectors, the handling of volatile chemicals is a routine task. For instance, in the pharmaceutical industry, these evaporators are used for the concentration of drug formulations, where controlling the temperature and preventing contamination are crucial.

Similarly, in the petrochemical industry, they are used for purifying oils and other hydrocarbons. The Explosion Proof design is vital here due to the highly flammable nature of the materials being processed. In the perfume industry, these devices are used to extract and concentrate fragrances from natural sources, a process often involving a range of volatile organic solvents.

The Role of Explosion Proof Rotary Evaporators in Safety

The role of Explosion Proof Rotary Evaporators in maintaining safety in laboratories and industrial settings is undeniable. These devices significantly lower the risk of accidents, ensuring a safer working environment. They are not just a piece of equipment but a crucial part of a comprehensive safety strategy in any laboratory or facility dealing with hazardous materials.

Incorporating these evaporators into regular laboratory procedures not only aligns with regulatory compliance but also fosters a culture of safety. They are a testament to the industry's commitment to protecting personnel and property from the inherent risks associated with handling volatile substances.

Conclusion

In conclusion, the Explosion Proof rotary evaporator is an indispensable tool for ensuring safety and efficiency in any laboratory or industry dealing with volatile substances. Its importance in maintaining operational standards and preventing accidents is unparalleled. ZZKD Machinery and Instrument Equipment Co., Ltd. offers a range of these sophisticated devices, each tailored to meet specific industry needs.

For those looking to enhance their laboratory's safety and operational capabilities, exploring the range of Explosion Proof Rotary Evaporators offered by ZZKD is a crucial step. Visit ZZKD's website to learn more about their products, understand the technical specifications, and make an informed decision on how to safeguard your laboratory environment while boosting efficiency.