-

WhatsApp

-

Email

In the realm of chemical and biological pharmaceutical equipment, safety is paramount. This is especially true when it comes to processes involving volatile solvents and potentially explosive substances. One piece of equipment that plays a critical role in such scenarios is the explosion-proof rotary evaporator. In this article, we delve into this essential apparatus, exploring its significance, applications, and key considerations. Join us on a journey through the world of Laboratory Rotary Evaporator.

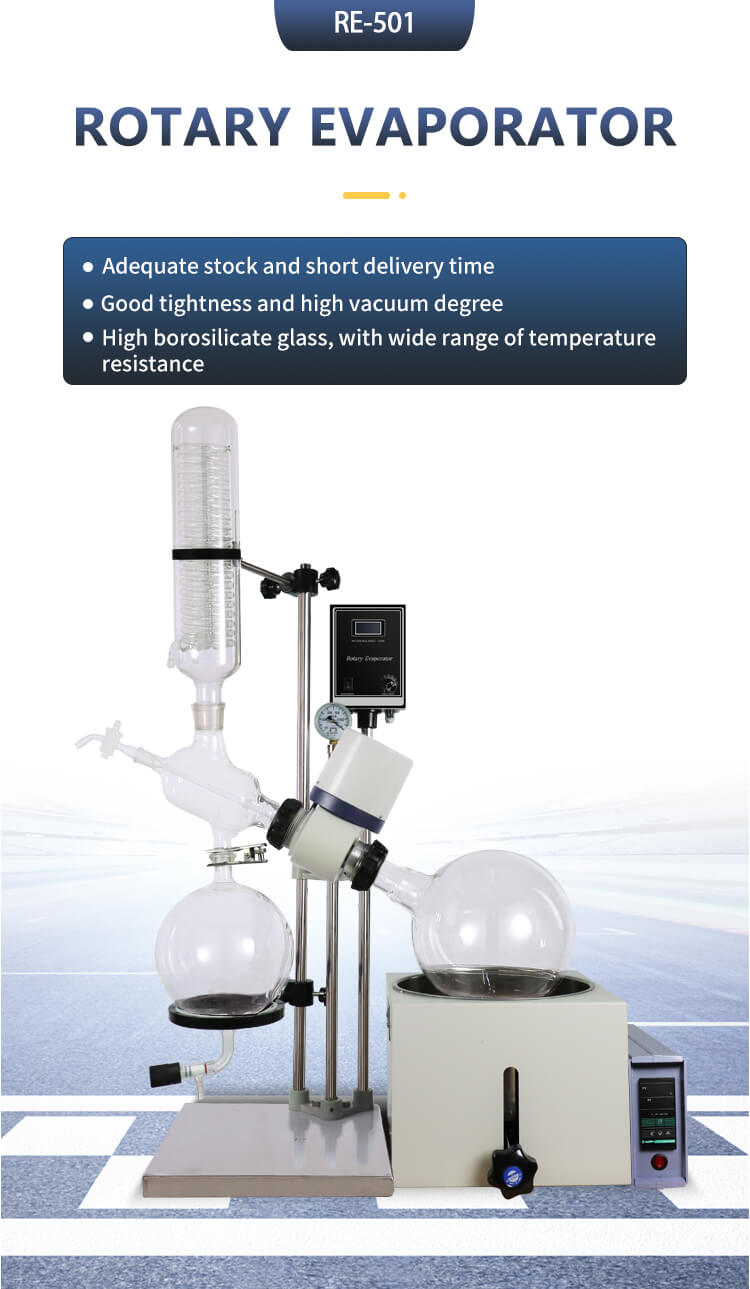

Before we delve into the specifics, it's crucial to understand the fundamentals. A rotary evaporator, often referred to as a rotovap, is a laboratory apparatus used for efficient and gentle removal of solvents from samples by evaporation. It consists of a vacuum system, a rotating flask, and a heating bath. This design allows for the controlled evaporation of solvents, leaving behind the desired substances, such as concentrated extracts or isolated compounds.

The Significance of Explosion-Proof Design

1. Enhanced Safety Measures:

When dealing with volatile and potentially explosive solvents, safety should always be the top priority. Explosion-proof rotary evaporators are designed to minimize the risks associated with these substances. They are equipped with features that prevent sparks, arcs, or any other potential ignition sources from coming into contact with the surrounding atmosphere.

2. Compliance with Regulations:

In the chemical and pharmaceutical industries, strict regulations govern the handling of hazardous materials. Explosion-proof equipment ensures compliance with these regulations, offering peace of mind to operators and facility managers.

3. Versatility in Application:

Explosion-proof rotary evaporators find application in a wide range of industries, from petrochemicals to pharmaceuticals. Their versatility makes them indispensable for processes involving flammable or explosive substances.

Key Components and Operation

1. The Rotating Flask:

At the heart of the rotary evaporator is the rotating flask. This flask holds the sample and solvent to be evaporated. The rotation of the flask creates a thin film of the solvent on the inner surface, promoting efficient evaporation.

2. The Heating Bath:

The heating bath provides the necessary heat for evaporation. It's essential to control the bath's temperature carefully, ensuring that the process is both efficient and safe.

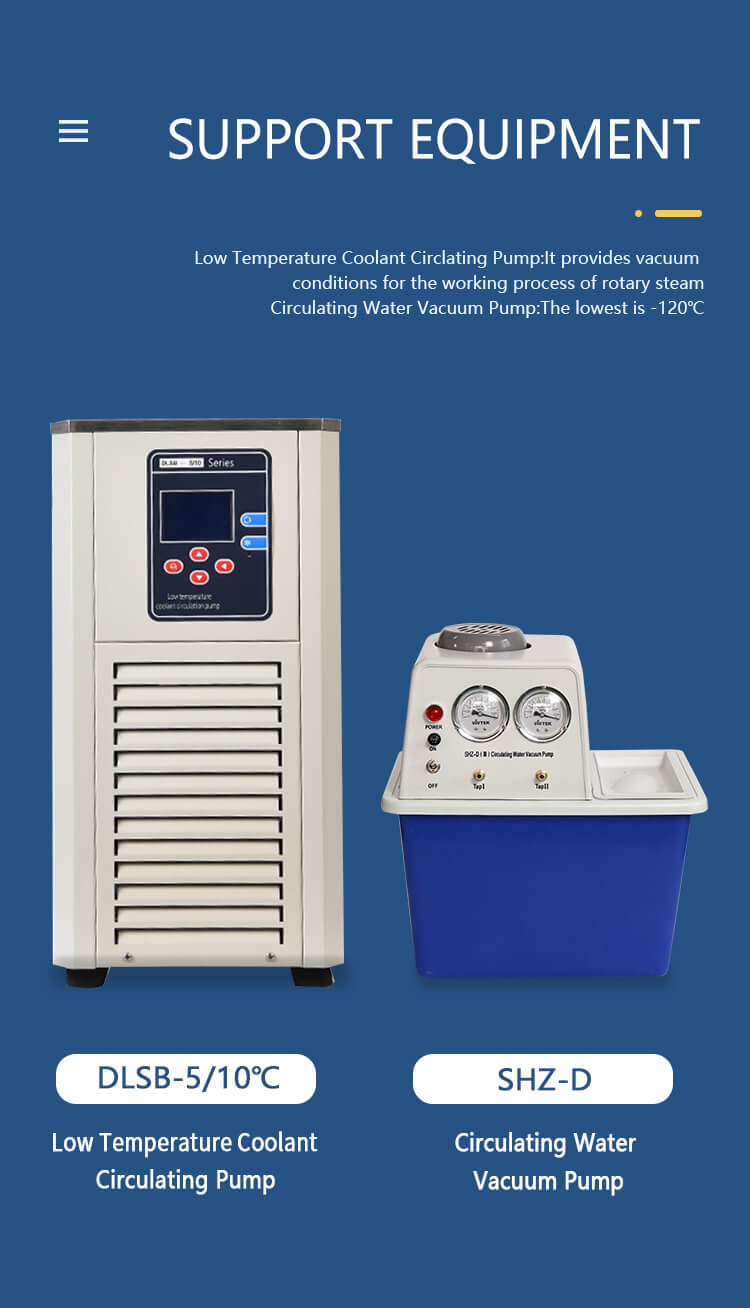

3. Vacuum System:

The vacuum system lowers the pressure in the system, reducing the boiling point of the solvent. This accelerates the evaporation process while minimizing the risk of overheating.

Applications in Various Industries

Explosion-proof rotary evaporators are employed in a wide array of industries. Here are a few examples:

1. Pharmaceuticals:

In pharmaceutical research and production, these rotary evaporators are used to concentrate or isolate active pharmaceutical ingredients (APIs) from solvents. The explosion-proof design ensures the safety of valuable and potentially hazardous compounds.

2. Petrochemicals:

The petrochemical industry often deals with flammable and explosive substances. Explosion-proof rotary evaporators are vital for processing these materials safely, such as refining crude oil or extracting volatile components.

3. Chemical Synthesis:

In chemical synthesis laboratories, these devices assist in solvent removal, enabling researchers to obtain pure compounds with minimal contamination.

Ensuring Operational Safety

1. Regular Maintenance:

To ensure the continued safety and efficiency of explosion-proof rotary evaporators, regular maintenance is crucial. This includes checking for any signs of wear and tear, testing safety features, and keeping a maintenance log.

2. Proper Training:

Operators should be well-trained in the use of explosion-proof equipment. Understanding the principles and safety protocols is essential to prevent accidents.

3. Emergency Response:

In the event of an unexpected incident, having a well-defined emergency response plan is essential. This plan should include procedures for evacuating the area and addressing potential hazards.

Conclusion

In the world of chemical and biological pharmaceutical equipment, the explosion-proof rotary evaporator stands as a sentinel of safety. Its design and applications make it a critical tool in industries dealing with volatile and potentially explosive substances. Understanding its significance and the measures for safe operation is key to harnessing its potential without compromise. Remember, when it comes to safety in chemical processes, the explosion-proof rotary evaporator is a guardian you can rely on.