-

WhatsApp

-

Email

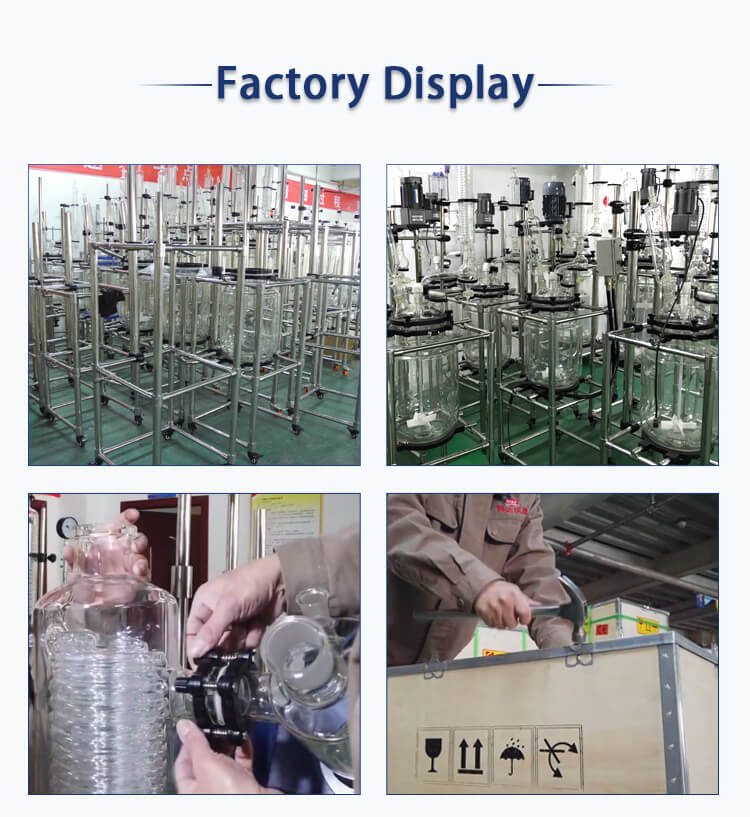

The world of laboratory equipment is witnessing a significant transformation with the advent of the electric glass reactor kettle. A standout in this realm is the 10L jacketed glass reactors vessel, which has become a staple in labs across various industries. These kettles are designed to facilitate a wide range of chemical reactions under controlled conditions, making them indispensable for researchers and scientists.

The Design and Features of Modern Reactor Kettles

Modern electric glass reactor kettles are a marvel of engineering. They incorporate robust glass construction with precise electric heating systems. This design allows for clear observation of reactions while ensuring even heat distribution. Features such as variable speed stirring, temperature control, and inert gas introduction contribute to their versatility and efficiency in the lab.

The Role of Electric Glass Reactor Kettles in Research

In research environments, electric glass reactor kettles are crucial. They provide a controlled environment for conducting experiments, which is vital for replicating results. Their precision in temperature and stirring speed control allows for detailed exploration of reaction kinetics and pathways, essential for groundbreaking research.

Safety Features in Electric Glass Reactor Kettles

Safety is paramount in laboratory settings, and electric glass reactor kettles are designed with this in mind. They come equipped with features like over-temperature shut-off, pressure relief mechanisms, and shatter-resistant glass. These features ensure the safety of laboratory personnel and the integrity of experiments.

Electric Glass Reactor Kettles in Industrial Applications

Industries ranging from pharmaceuticals to petrochemicals rely on electric glass reactor kettles. Their ability to handle a variety of chemical reactions, from polymerization to crystallization, makes them invaluable. They offer scalability and consistency, key factors in industrial processes.

The Environmental Impact of Using Electric Glass Reactor Kettles

Electric glass reactor kettles also contribute positively to environmental sustainability. Their efficient energy use reduces the carbon footprint of laboratories. Additionally, their precision in chemical handling minimizes waste generation, aligning with eco-friendly practices.

The Future of Electric Glass Reactor Kettles

The future of electric glass reactor kettles is promising, with continuous innovations enhancing their capabilities. Developments in automation and integration with digital monitoring systems are set to elevate their efficiency and ease of use further.

Conclusion: Embracing the Advancements in Electric Glass Reactor Kettles

In conclusion, electric glass reactor kettles, like the 10L jacketed glass reactors vessel from ZZKD Machinery and Instrument Equipment Co., Ltd., are transforming laboratory operations. They offer a blend of safety, efficiency, and versatility, making them an essential component in modern scientific research and industrial applications. For more information and to explore a range of high-quality distillation and extraction equipment, visit ZZKD’s website and discover how they can contribute to your laboratory’s success.