-

WhatsApp

-

Email

The supercritical extraction equipment produced by ZZKD laboratory equipment manufacturer is highly intelligent and multi-modular. High intelligence will be reflected in the operation, which can make it easier for users to get started. Multi-module means that the modular functional unit of the device can be expanded at any time. Below we will give a brief introduction to supercritical fluid technology and supercritical extraction unit. Friendly reminder, there is a little egg at the end of the article!

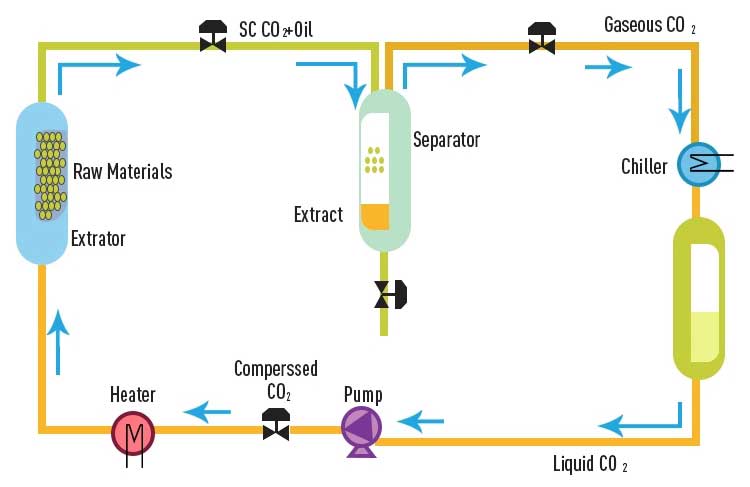

Supercritical extraction principle

Supercritical fluid extraction technology is currently the most advanced physical separation technology in the world.

In common supercritical fluids, due to the stable chemical properties of CO2, non-toxic and non-corrosive, non-flammable and non-explosive, the critical state is easy to achieve, and its critical temperature (31.1 ℃) is close to normal temperature. Rich in aroma components, physiologically active substances, enzymes or proteins and other heat-sensitive substances have no destructive effect, so currently in practical applications, CO2 is often used as the extraction medium for supercritical extraction.

Since the density of supercritical CO2 is very sensitive to changes in temperature and pressure, adjusting the pressure or temperature of CO2 can adjust the density of CO2, and then the ability to dissolve the target extract in the raw material.

During the supercritical extraction process, the extracts obtained at various pressures or temperature ranges are not single. The conditions can be controlled to obtain the optimal proportion of the mixed components. Then, the supercritical fluid is turned into an ordinary gas by means of pressure reduction and temperature rise. The extracted substances are completely or basically separated, so as to achieve the purpose of separation and purification-this is a conventional supercritical CO2 extraction process.

Supercritical extraction device

Supercritical extraction equipment is a device (instrument) that uses the characteristics of supercritical fluid to extract and separate target components in raw materials under suitable operating conditions.

Conventional supercritical extraction devices generally include extraction systems, separation systems, pressurization systems, heat exchange systems, safety systems, and control systems. On this basis, according to different materials, different target components, and different use scenarios, the device needs to be configured with various other functional auxiliary systems, and the design parameters, configuration, equipment composition, key equipment structure and style are also different. Not the same. Therefore, in addition to teaching-use instruments, most supercritical extraction devices need to be designed and customized differently according to customer needs.

Supercritical extraction devices commonly use CO2, but there are also other fluids such as ethanol, methanol, propane, butane, and pentane as medium for the design of supercritical extraction equipment.

What is supercritical fluid extraction technology?

Supercritical fluid (SCF) refers to fluids above the critical temperature and pressure. A state close to a critical point above a critical temperature and a critical pressure is called a supercritical state. The principle of supercritical fluid extraction and separation process is based on the relationship between the solubility of supercritical fluid and its density, that is, the effect of pressure and temperature on the solubility of supercritical fluid. In the supercritical state, the supercritical fluid has good fluidity and permeability. The supercritical fluid is in contact with the substance to be separated, so that it can selectively extract the components of polar size, high and low boiling point, and molecular weight in order. come out. Of course, the extracts obtained for each pressure range cannot be single, but the conditions can be controlled to obtain the optimal proportion of the mixed components, and then the supercritical fluid is turned into an ordinary gas by means of pressure reduction and temperature rise. Complete or basic precipitation, so as to achieve the purpose of separation and purification, so in the supercritical fluid extraction process is a combination of extraction and separation.

Supercritical CO2 fluid characteristics

1.Low critical temperature, suitable for extraction and purification of heat sensitive compounds

2. Can provide an inert environment, avoid product oxidation, and do not affect the effective ingredients of the extract.

3.No solvent residues, no nitrates and heavy metal ions

4. Fast extraction speed, non-toxic, non-flammable, safe to use and not polluting the environment.

Above we have introduced the core technology of supercritical CO2 extraction equipment, supercritical CO2 fluid technology, and below we will discuss what are the characteristics of supercritical CO2 extraction equipment, work flow, and use.

Structure of supercritical CO2 extraction device

The device is mainly composed of extraction kettle, separation kettle, rectification column, C ○ 2 high pressure pump, carrier pump, refrigeration system, heat exchange system, purification system, extraction tank voltage stabilization system, C ○ 2 storage tank, flow meter, temperature , Pressure control protection, computer acquisition system and other components.

The main technical parameters

1. Extraction kettle: 05L, 1, 2L, 5L / 50Mpa, 10L, 24L / 4OMpa, 50-200L / 32Mpa, dual-use solid and liquid. The water distribution jacket can be used cyclically and the temperature can be adjusted.

2. Separation kettle: 03-10L / 30Mpa, 50-200L / 16-22Mpa. The water distribution jacket can be used cyclically and the temperature can be adjusted.

3.Inner diameter of distillation column ①25 × 2-3m / 30Mpa, ①35 × 2-3m / 3OMpa, Φ48X4-6m / 30Mpa, ①78x4-6m30Mpa can also be divided into 4 sections, 6 sections, 8 sections gradient temperature control according to process requirements ; The user can choose related packing in the column according to the process requirements

4.Co2 high pressure pump: 20L / 40Mpa · h three plunger frequency modulation, 50L / 50Mpa · h three plunger frequency modulation, 400L / 40Mpa · h three plunger frequency modulation, 800L / 40Mpa · h three plunger frequency modulation, pump head with cooling system.

5. The carrier pump is used in the extraction process to carry the solvent to change the polarity of CO2 and expand the scope of application.

6. Refrigeration system: equipped with semi-hermetic and hermetic compressors, the refrigeration capacity meets the process requirements

7.Heat exchange and temperature control system: According to the process requirements, the extraction kettle, separation kettle, and distillation column are equipped with heat exchange and temperature control systems respectively. Double screen control water bath temperature, test CO2 fluid temperature, temperature control accuracy ± 1 ℃.

8. Pressure control (protection): high pressure pump outlet distribution contact pressure gauge, set working pressure, over-pressure protection automatically stops the pump. The high-pressure pump, extraction kettle, separation kettle, and distillation column are equipped with safety valves according to the highest working pressure, and automatic pressure relief protection for overpressure. The outlet of the extraction kettle is equipped with a back pressure valve system. Ensure the pressure is stable, easy to adjust, and the pressure control accuracy is ± 0.1Mpa.

9.Flow display: metal rotor flowmeter, digital display remote transmission, showing instantaneous flow and accumulated flow respectively

10. Pipeline: Containers, valves, fittings and pipelines in contact with fluid are made of stainless steel

11. Others: Power supply three-phase four-wire system 380V / 50Hz, CO2 food grade ≥99.5%, user-supplied.

Features of supercritical CO2 extraction device

1. Extraction can be performed at near room temperature (35-40 ° C) and under the cover of CO2 gas, which effectively prevents the oxidation and escape of heat-sensitive substances, retains biological activity intact, and has high boiling point, low volatility and easy pyrolysis The substance is extracted below its boiling temperature.

2. Because no organic solvent is used in the whole process, the extract has no residual solvent, and it also prevents the poisoning of the human body and the pollution of the environment during the extraction process. Pursuit of high taste.

3. Controlling process parameters can separate different products, which can be used to extract a variety of products, which is particularly beneficial to the extraction of pure natural products from natural plants and animals and the extraction of Chinese herbal medicine.

4. Heavy metals, inorganics, dust, etc. in the raw materials will not be carried out by CO2 dissolution.

5. The CO2 carried out when the product is discharged is automatically dissipated or some CO2 is retained after the product enters the packaging container, which is sealed with a cap and used as a preservative to extend the shelf life.

6. Integration of extraction and separation, the process is very simple.

7. Easy to use computer monitoring to ensure safety and realize unattended workshop.

8. In a closed high-pressure system, all bacteria are killed, and the product is discharged directly from the separator under pressure to the packaging container, which is easily certified by GMP.

9. Low energy consumption; hot water and cold water are all circulated in a closed circuit, and no waste water or waste residue is discharged. CO2 is also a closed circuit, which only brings out a small amount during discharge, which will not pollute the environment.

10. Due to less energy consumption, less labor, and less material consumption, the operating costs are very low.

Basic process and combined form of supercritical C02 extraction device

Basic process

1. Separation of CO2 benzene from the kettle

2.CO2-extraction kettle one separation | one separation‖ one distillation column one circuit

3.CO2—extraction kettle—distillation column—separation | separation‖loop

4.CO2-extraction kettle one separation | rectification column one separation‖primary circuit

Process can be increased according to process requirements

1. CO2-rectification column at the bottom of a separation | separation | a loop. Simultaneous raw material (liquid)-continuous extraction of liquid raw material in the middle of the distillation column (countercurrent)

2. Separation | or separation | (separation) a pair of pumps-the middle of the distillation column.

Combination

Extract one-fraction, one-extract dichotomy, one-extract dichotomy and one-column, two-extract dichotomy, two-extract dichotomy and one-column, four-extract dichotomy, four-extract dichotomy and one-column, or according to the user's special combination process.

Application area

For university teaching, and extraction of natural products, effective ingredients of Chinese herbal medicine, edible oils and fats for health benefits, pesticide residues, heat sensitivity, biologically active ingredients, natural flavors, spices, low-boiling volatile ingredients, and separation and purification of mixtures in chemicals, etc. Research, pilot test and industrial production in the field.

Some little secrets

Extraction of precious spices in plants-will not change the essence of spices, high yield and good quality.

Extraction of natural medicines-Extraction of whole extracts and essential oils of natural medicinal materials.

Extraction of natural health products from natural materials-such as seabuckthorn oil, wheat germ oil, lecithin, etc.

Caffeine removal and production of caffeine from coffee and tea.

Extraction and purification of DHA and EPA from fish oil.

Removal and extraction of nicotine in tobacco.

Others-such as separation and refining of oil products, high-pressure polymerization environmental protection engineering, fine ceramics and printing and dyeing.