-

WhatsApp

-

Email

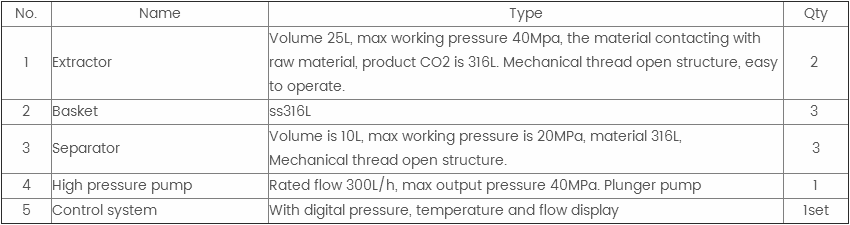

The extraction kettle and the separation kettle of the supercritical extraction equipment have the dual functions of heating and cooling. And the use of alloy material as the screw head of the extraction kettle not only reduces the strength, but also reduces the weight of the head, making it more convenient to operate;

Features

- It can be extracted in the presence of CO2 near room temperature (35- 40 ℃), effectively preventing the oxidation and overflow of heat sensitive substances.

- Using SFE is the cleanest extraction method, because the entire process does not use organic solvents, so the extract has no residual solvents, and it can also prevent human poisoning and environmental pollution.

- CO2 is cheap, high purity, and easy to obtain and circulate during the production process, thereby reducing costs.

- Fast extraction speed and strong liquid extraction ability, especially suitable for solid material separation and extraction.

- Because its energy consumption is lower than that of ordinary distillation, it is suitable for separating heat- sensitive substances from oxidizable substances.

- Fast heat transfer and easy temperature control.

- Suitable for separation of volatile substances.

Detail

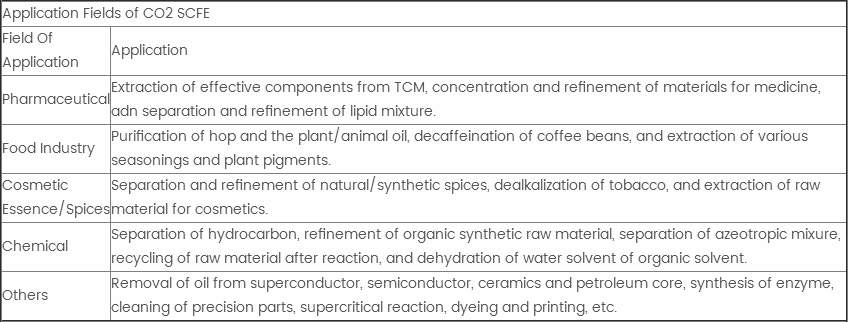

Application of supercritical CO2 extraction machine:

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

Accessories for supercritical extraction equipment:

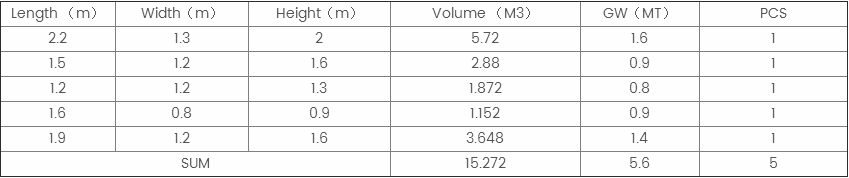

Packaging parameters of supercritical extraction system:

1. The advantages of co2 supercritical extraction equipment:

-Convenient and reliable operation and control methods, two modes of instrument semi-automatic and PLC automatic control can be selected;-Industrial design mode can meet the needs of continuous production;

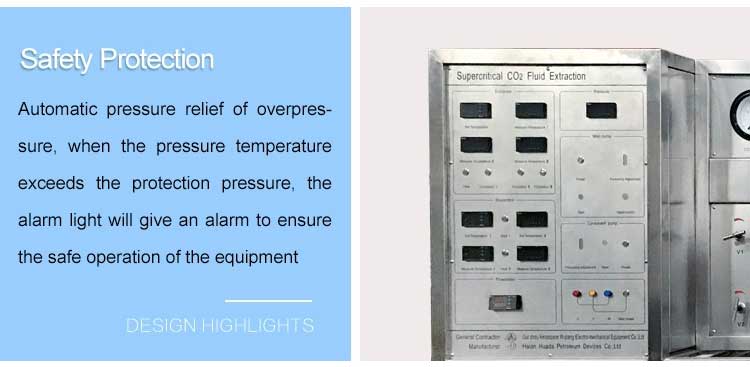

-Double security protection, specifically:

1)The high pressure pump is equipped with a pressure gauge and the overpressure stops the pump.

2)Pressure vessels such as high-pressure pumps, extraction kettles, and separation kettles are equipped with safety pressure relief valves. Overpressure is automatically released by pressure. When the pressure and temperature exceed the protective pressure, the alarm lamp will issue an alarm and prompt to ensure the safe operation of the equipment;

--It can be customized design and production to meet your special needs;

-All stainless steel containers and pipeline valves are made of sanitary SS304 or SS316;

2. Technology application of supercritical extraction equipment:

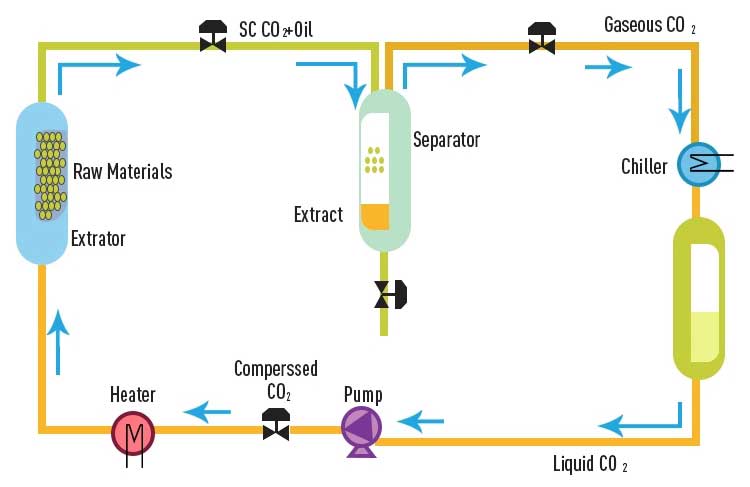

Extraction of sea buckthorn oil, caffeine in coffee beans, removal of nicotine from tobacco, extraction of coffee flavors, extraction of useful ingredients in hops, extraction of high-purity oil, cholesterol in soybean oil and egg yolk, and extraction of allicin.Supercritical CO2 extraction technology is the most advanced, green and environmentally friendly extraction and separation technology. It uses supercritical CO2 fluid to have special dissolving properties at critical pressure and temperature for separation and purification.