-

WhatsApp

-

Email

Molecular distillation is a more precise distillation device than the short-path distillation kit. Many things it can do cannot be done by short path distillation equipment. Many people do not know what molecular distillation is, what molecular distillation equipment can do, how short path molecular distillation works, what are the characteristics of vacuum molecular distillation, and so on. These questions will be answered in this article.

What is molecular distillation?

Molecular distillation equipment is a German company specializing in distillation equipment design and manufacturing company in 1950 produced the first generation of molecular distillation equipment, after various improvements and research and development now has the current molecular distillation equipment. Although molecular distillation has been around for a long time, many people still don't understand it. So what is molecular distillation?

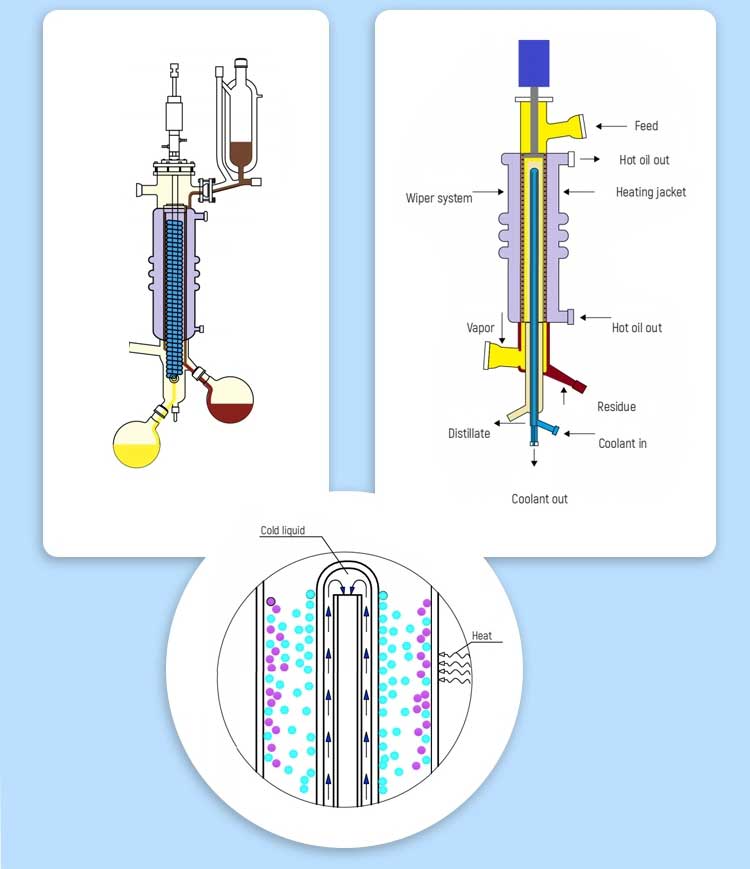

Molecular distillation is a distillation method operated under high vacuum. At this time, the average free path of the vapor molecules is greater than the distance between the evaporation surface and the condensation surface, so that the difference in evaporation rate of each component in the liquid can be used for liquid mixtures. Perform separation. It differs from the traditional distillation by the principle of boiling point difference separation, but by the difference in the average free path of the molecular motion of different substances to achieve separation.

The main component of molecular distillation is a short-path evaporator. All work is done by this short-path evaporator, so we usually call it short-path molecular distillation.

What are the uses of molecular distillation equipment?

Molecular distillation equipment can be used in food industry, fine chemical industry, pharmaceutical industry and other industries.

The food industry can carry out the production of monoglycerides, the refining of fish oil, the deacidification of fats and oils, the refining of high-carbon alcohols, and the extraction of CBD oil.

In fine chemicals, it can be used for the purification of aromatic oils, the purification of high polymer intermediates, and the extraction of lanolin.

In the pharmaceutical industry, natural vitamin A and vitamin E can be extracted, and amino acid and glucose derivatives can be produced, as well as carrots and carotenoids.

As a special new separation technology, molecular distillation technology is mainly applied to the purification and separation of high boiling point and heat sensitive materials. Practice has proved that this technology not only has high scientific and technological content, but also has a wide range of applications. It is a high and new technology with broad industrial application prospects.

How does short-path molecular distillation work?

The main working element in the molecular distillation system is the short-path evaporator. The short-path still performs liquid-liquid separation, which is achieved by the difference in the average free path of the molecular motion of different substances.

When the liquid mixture flows along the heating plate and is heated, light and heavy molecules will escape from the liquid surface and enter the gas phase. Due to the different free paths of light and heavy molecules, the molecules of different substances will move at different distances after they escape from the liquid surface. If a condensing plate can be properly set, light molecules reach the condensing plate and are condensed and discharged, while heavy molecules cannot reach the condensing plate and are discharged along the mixed liquid. In this way, the purpose of material separation is achieved.

The pressure difference between the boiling film and the condensing surface is the driving force of the steam flow direction, and a small pressure drop will cause the steam flow. Operating at 1 mbar requires a very short distance between the boiling surface and the condensing surface. A distiller made based on this principle is called a short path distiller. The short-path evaporator (molecular distillation) has a built-in condenser opposite the heating surface and reduces the operating pressure to 0.001 mbar.

Short-path evaporator is a thermal separation technology process that operates at a pressure of 1 to 0.001 mbar. Its low boiling temperature is very suitable for heat-sensitive and high-boiling substances. Its basic composition: a cylindrical barrel with a heating jacket, a rotor and a built-in condenser; a fixed frame of the rotor is precisely equipped with a scraper and an anti-splash device. The built-in condenser is located in the center of the evaporator, and the rotor rotates between the cylindrical barrel and the condenser.

The short path distiller consists of an externally heated vertical cylinder, a central condenser located at it, and a scraper rotating between the distiller and the condenser.

The distillation process is: the material is added from the top of the evaporator, and it is continuously and evenly distributed on the heating surface through the material liquid distributor on the rotor, and then the film scraper scrapes the material liquid into a thin, turbulent liquid film And advance downwards in a spiral. In this process, light molecules that escape from the heating surface condense into liquid on the built-in condenser after a short route and almost without collision, and flow down the condenser tube through the discharge tube at the bottom of the evaporator. Drain; the residual liquid is the heavy molecules collected in a circular channel under the heating zone, and then flows out through the side discharge tube.

What are the advantages of vacuum molecular distillation?

1. The distillation temperature is low. The molecular distillation is operated at a temperature far below the boiling point. As long as there is a temperature difference, the separation can be achieved. This is the essential difference between molecular distillation and conventional distillation.

2. The vacuum degree of distillation is high, and the inside of the molecular distillation device can obtain a high degree of vacuum. Usually, molecular distillation is operated at a very low pressure, so the material is not easy to be damaged by oxidation.

3. Thin distillate film, high heat transfer efficiency.

4. The material is heated for a short time, and the distance between the heated liquid surface and the condensing surface is less than the average free path of the light molecules, so the light molecules escaping from the liquid surface reach the condensation surface almost without collision. Therefore, the heating time of the distillation material is short, and the residence time at the distillation temperature is generally between several seconds and tens of seconds, which reduces the chance of thermal decomposition of the material.

5. Higher degree of separation, molecular distillation can separate conventionally difficult to separate materials

6. There is no boiling and bubbling. Molecular distillation is free evaporation on the surface of the liquid layer. It is carried out under low pressure. There is no dissolved air in the liquid. Therefore, the entire liquid cannot be boiled during the distillation process and there is no bubbling.

7. Non-toxic, harmless, pollution-free, no residue, pure and safe products can be obtained, the operation process is simple, and the equipment is few. Molecular distillation technology can separate substances that are not easily separated by conventional distillation.

8. Molecular distillation equipment is expensive. The molecular distillation device must ensure a high degree of vacuum in the system pressure. It requires high material sealing. The distance between the evaporation surface and the condensation surface must be moderate. The equipment is difficult to process and the cost is high.

9. The product consumes less energy, because the molecular distillation has a small overheating loss due to the entire separation, and because of the unique structure of the molecular distillation device, the internal pressure is extremely low and the internal resistance is much smaller than conventional distillation, which can greatly save energy consumption.

Molecular distillation equipment has the following obvious advantages.

From the above characteristics of molecular distillation technology, it is known that it has the following obvious advantages over conventional distillation technology in practical industrial applications:

● For the separation of high boiling point, heat sensitive and easy oxide materials, molecular distillation provides the best separation method. Because molecular distillation is operated at a temperature far below the boiling point of the material, and the material residence time is short;

● Molecular distillation can very effectively remove substances in liquids such as organic solvents, odors, etc., which is a very effective method for liquid dissolution after solvent extraction;

● Molecular distillation can selectively evaporate the target product, remove other impurities, and can separate more than two substances at the same time through multi-stage separation;

● The molecular distillation fractionation process is a physical process, so it can well protect the separated materials from pollution and damage.

Classification of molecular distillation equipment.

There have been three types of molecular distillation from the birth to the present after a long period of development and renewal. 1. Falling film molecular distillation. 2. Scrap film molecular distillation. 3. Centrifugal molecular distillation.

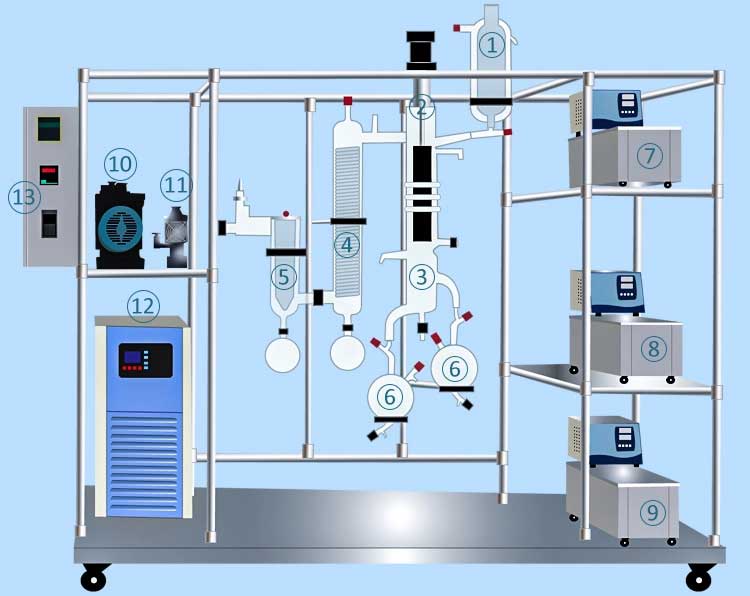

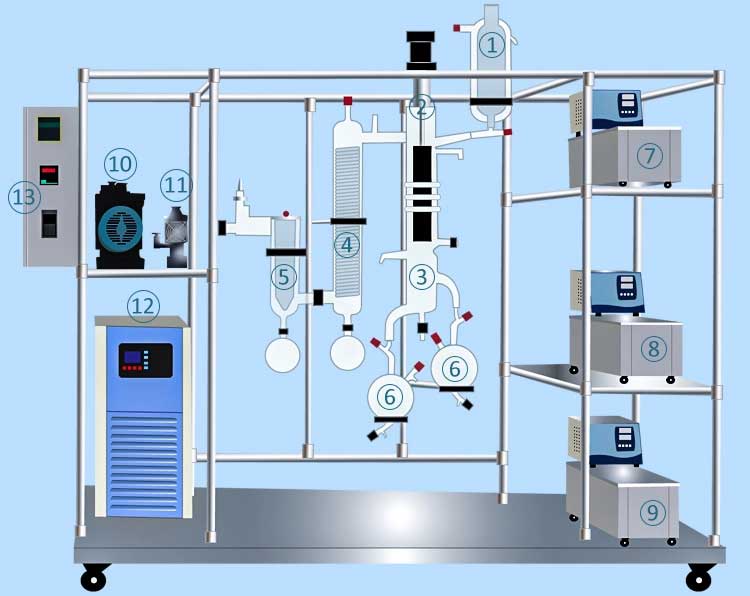

A complete set of molecular distillation equipment mainly includes: molecular evaporator, degassing system, feeding system, heating system, cooling vacuum system and control system. Due to the different molecular evaporators of the core components of the molecular distillation device, the molecular distillation equipment is divided into three different types. What are the advantages and disadvantages of these three molecular distillation equipment?

Falling film type: It is an early form and has a simple structure. However, due to the thick liquid film and poor efficiency, it is rarely used in countries around the world today.

Wiped film type: the liquid film formed is thin and the separation efficiency is high, but the structure is more complicated than the falling film type.

Centrifugal type: film formation by centrifugal force, thin film, high evaporation efficiency, but complex structure, difficult vacuum sealing, and high equipment manufacturing cost. In order to improve the separation efficiency, it is often necessary to use multiple stages in series to achieve the multi-stage separation of different substances.

In summary, the short-path evaporator device is the core component of molecular distillation equipment, and its changes will affect the operation mode and working efficiency of the entire molecular distillation equipment.