-

WhatsApp

-

Email

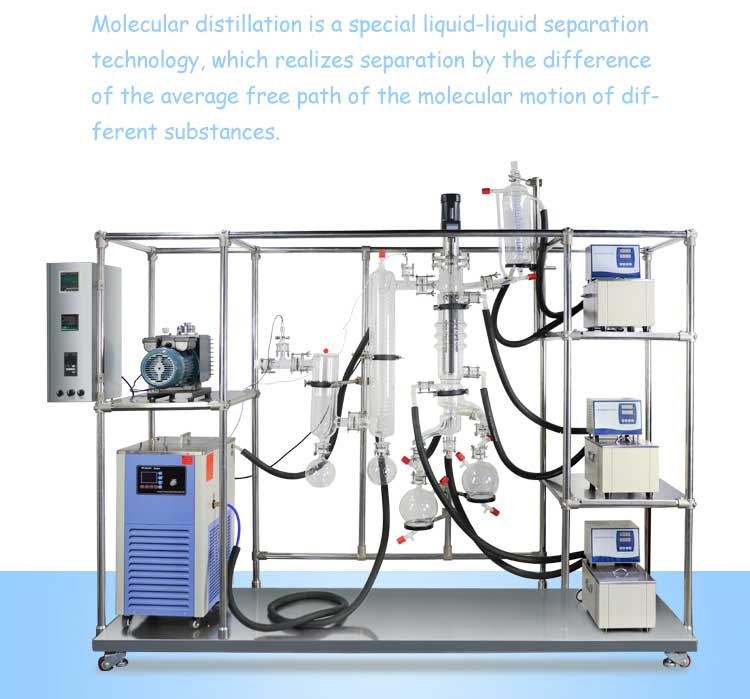

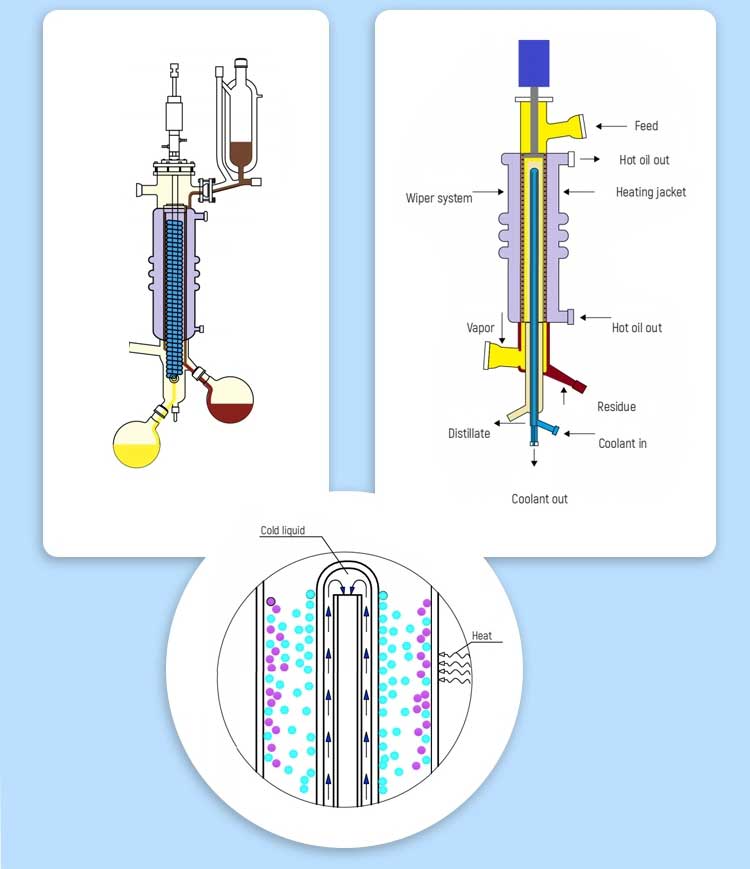

Molecular distillation equipment is a distillation method operated under high vacuum. At this time, the average free path of the vapor molecules is greater than the distance between the evaporation surface and the condensation surface, so that the difference in evaporation rate of each component in the liquid can be used. The mixture was separated.

The molecular distillation system at a certain temperature, the lower the pressure, the greater the average free path of the gas molecules. When the pressure of the evaporation space is very low (10-2 to 10-4 mmHg), and the condensation surface is close to the evaporation surface, and the vertical distance between them is smaller than the average free path of the gas molecules, the vapor molecules vaporized from the evaporation surface may not be related to Other molecules collide and directly reach the condensation surface to condense.

Features

- Very high evaporation efficiency, which reduces retention time with minimal time delay.

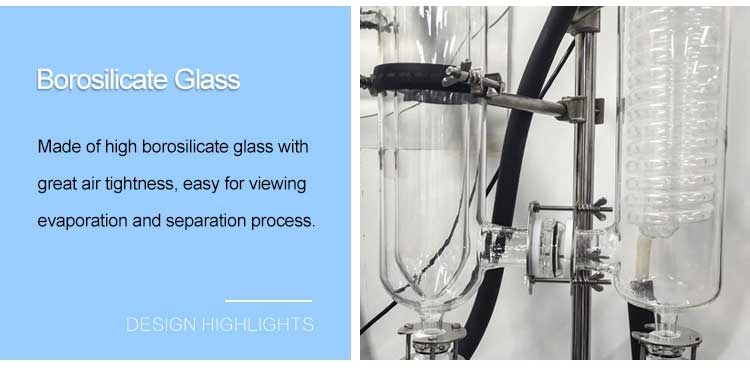

- The molecular distillation system is composed of high borosilicate glass, stainless steel and PTFE, so it has excellent corrosion resistance.

- The main body of the molecular distillation system is made of high borosilicate glass, which can well observe the operation of the entire process.

- The high-precision still body makes the liquid form a complete integrated film on the heated surface. The inner wall of the barrel is smooth and clean, the inner wall is smooth and bright, and it is not easy to stick and scale.

- Inverter geared motor, safe and reliable operation; with self-cooling fan, it can work continuously for a long time.

- The entire molecular distillation system has good sealing performance, and the minimum vacuum pressure can reach 0.1Pa.

- The maximum temperature of the system can reach 230 ° C / 300 ° C.

- The maximum theoretical vacuum can reach 5Pa or 0.1Pa.

- Squeegee film forming system and self-cleaning roller film forming system available.

Detail

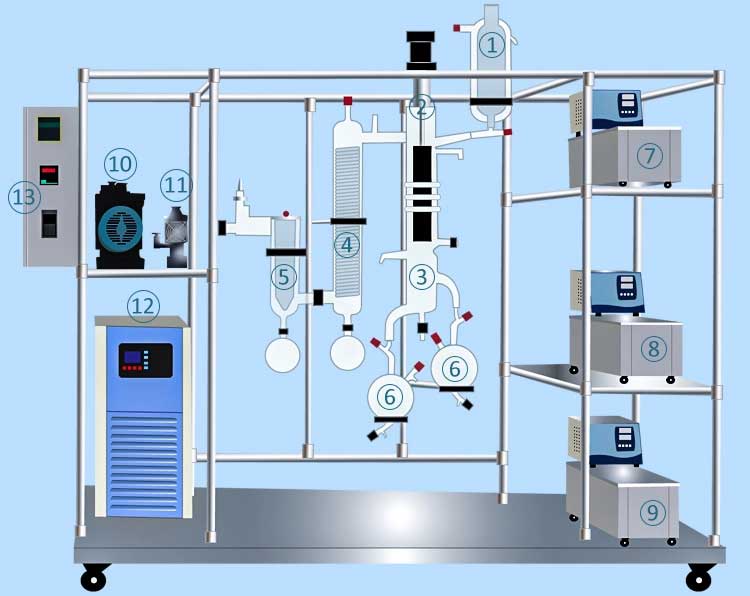

Vacuum equipment and condensation equipment for molecular distillation:

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. What is the capacity of your molecular distillation equipment?

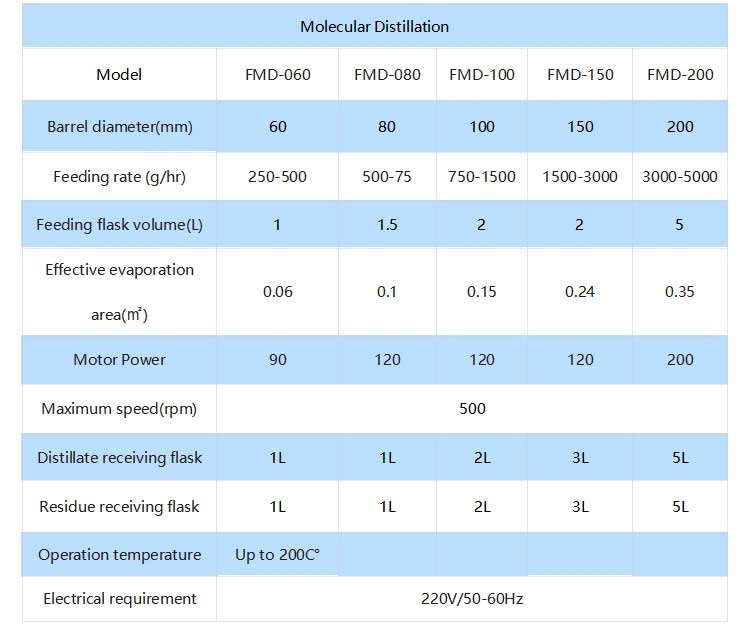

The molecular distillation equipment produced by our company has a capacity of 1L, 2L, 5L. When choosing to buy, choose to buy according to your actual needs.

2. What materials are used to make up the components of a molecular distillation system?

The molecular distillation system is composed of 3.3 high borosilicate glass, 316L stainless steel, and PTFE, so it has excellent corrosion resistance. The maximum theoretical vacuum can reach 5Pa or 0.1Pa.

3. The operation process of molecular distillation.

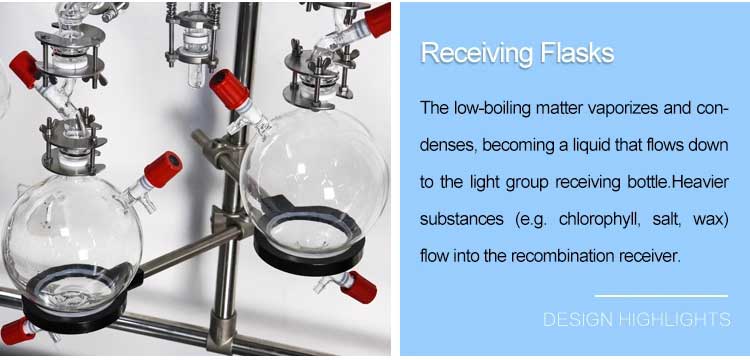

The distillation process is: the material is added from the top of the evaporator, and it is continuously and evenly distributed on the heating surface through the material liquid distributor on the rotor, and then the material scraper scrapes the material liquid into a thin, turbulent liquid film And advance downwards in a spiral. In this process, light molecules that escape from the heating surface condense into liquid on the built-in condenser after a short route and almost without collision, and flow down the condenser tube through the discharge tube at the bottom of the evaporator. Drain; the residual liquid is the heavy molecules collected in a circular channel under the heating zone, and then flows out through the side discharge tube.