-

WhatsApp

-

Email

What is molecularly distillation monoglyceride?

Molecularly distilled monoglyceride is a glyceryl monostearate produced from natural vegetable oils and fats, referred to as monoglyceride, which is purified by molecular distillation technology to reach more than 90% of active ingredients. It is also called molecularly distilled monoglyceride. A wide range of food additives are safely used in the production and processing of food, medicine, plastics, etc., accounting for more than half of the amount of emulsifier in the market.

In molecularly distilled monoglycerides, glycerol monostearate with emulsifier content is higher, eliminating impurities that reduce efficiency, so the emulsifying ability is 3-4 times higher than crude esters, and it can generally be achieved by adding 0.05-2%. Food and other products need to be processed. They are white in color, odorless, and stable in performance.

Monoacylglyceride(MAC)

Monoglyceride uses molecular distillation technology to increase the content of monoglyceride to more than 90%. The product produced by this method is called molecularly distilled monoglyceride. Its production equipment mostly adopts rotary wiped film molecular distillation equipment, and its basic structure is an outer layer evaporator and an inner layer condenser and its moving wiper mechanism.

Molecularly distilled monoglyceride is a white waxy flake, bead, or powdery solid that is soluble in organic solvents such as chloroform, ethanol, acetone, or ether, as well as in mineral and nonvolatile oils. It is insoluble in water and can be dispersed in hot water by mixing with hot water. The molecularly distilled monoglyceride HLB value is between 3 and 4, and it belongs to the water-in-oil (W / O) type emulsifier. Due to its unique emulsification, it can also be used as an oil-in-water (O / W) type emulsifier. It is one of the "few food additives" recognized by the US Food and Drug Administration (FDA) and the Food and Drug Administration and the World Health Organization (FAO / WHO) as "generally recognized as safe" (GRAS), which are used without restrictions. , Is currently the world's most consumed food emulsifier.

Application fields of molecular distillation monoglyceride:

As people have higher and higher requirements for green, environmental protection, hygiene and safety, molecularly distilled monoglycerides are derived from natural raw materials. They have safe, effective and stable food additives and are more and more widely used in people's lives field. such as:

1. Food field: cake oil, cream, cold food, liquid solid beverage, dairy products, toffee, caramel, fruit candy, chocolate, bread, biscuits, peanut / walnut / bean / sesame / coconut butter (milk), sausage, ham Intestines, rice products, noodles, starch, etc.

2. Cosmetics field: cream

3. Medical field: plasters, nutrient solutions, etc.

4. Plastic additives: food packaging film, electrical packaging, sanitary materials, etc.

Method and dosage of molecular distillation monoglyceride:

Dosage: 0.1% -0.5% (based on the weight of the raw materials of the product formula). If the product contains more oil, protein and other ingredients, or contains raw materials that are not easily emulsified, the amount of molecularly distilled monoglyceride should be increased to 1% -5%.

1. Using the self-emulsifying feature of molecularly distilled monoglyceride, add one part of monoester to 10-20 parts of water, heat to 60-75 ° C, stir to dissolve, and make hydrated glyceride. Increased water solubility, stable and uniform emulsion after cooling, put it into raw materials, and carry out other process operations. It is recommended to choose this method, which can best exert the effect of molecular distillation of monoglyceride. Suitable for cold food, liquid drinks, solid drinks, cake oil, steamed bread, noodles, instant noodles, sausages and other products with low oil content.

2. As it is a lipid derivative, it has complete compatibility with fat injection and is easily soluble in oil. The distilled glycerol monoester is heated together with oil (≥65 ° C in a liquid state) and then mixed with water.

Suitable for producing cake oil, shortening, biscuits, cakes, pastries, ham sausages, canned meat products and other products with large oil content.

3. Mix it with other raw material powder and dissolve it at 60-75 water temperature when using.

Suitable for the production of pastry flour, dumpling flour, starch or bread, flour improver and other products.

Molecular distillation monoglyceride is a high-quality and high-efficiency edible emulsifier, which has the effects of emulsification, dispersion, stability, foaming, defoaming and anti-aging of starch. It is widely used in food, daily chemical, plastic, packaging and cosmetics industries. Molecularly distilled monoglycerol is completely non-toxic and harmless. There is no limit on human intake. It is a safe and high-quality food additive.

Recommended use:

1. Additives for food confectionery, used as emulsifier to add chocolate, margarine, ice cream, etc. or used as surfactant;

2. The application on rice noodle products can increase the tightness of dough and significantly improve the elasticity of noodles. Noodle products are not easy to mash when boiled, reduce turbidity of water, and taste good when eaten;

3. Application on ice cream can make the components of ice cream mix evenly, the organization is delicate and smooth, moderate swelling, good mouth solubility when tasting, avoid the formation of ice crystals, improve shape retention and storage stability;

4. Application on cakes, can be used as a foaming agent for cakes. Can promote the protein foaming property, can be a "protein-mono-ester" complex when making a cake, effectively help the cake to froth, and produce a stable bubble film, so as to produce stable and fine bubbles, with a significantly increased volume pastry.

5. Applications on edible oils and dairy products, such as margarine, shortening, peanut butter, mayonnaise, salad dressing, oyster sauce and other products, all need to add monoglyceride as emulsifier and stabilizer to adjust the crystallization of oil and prevent oil High moisture content and delamination occur, improving the quality of the products made. Condensed milk, malted milk, cheese, instant whole milk powder and other dairy products, monoglyceride is a good emulsifier, can improve

High-speed solubility, prevent precipitation, agglomeration, and improve product quality. Powder oil products such as coffee companion, Danganpu is its main emulsifier;

6. Application in beverages, adding soy milk, peanut milk, milk yogurt, cocoa milk, almond milk, etc., can significantly improve solubility and stability, prevent precipitation and separation, and extend the shelf life;

Molecularly distilled monoglyceride is an important emulsifier for making baked goods such as high-quality bread. By interacting with starch, protein, and fat, emulsifiers can increase the kneadability and mechanical resistance of the dough, and the resistance of the dough to changes in ingredients; reduce the "dough collapse and cracking" of the dough after it has been proofed; Helps to achieve maximum dough water absorption, and obtain higher product yield and product quality; anti-aging effect or soften the function of bread tissue to extend the bread freshness period; improve bread volume, bread loaf structure, bread internal organization structure and Texture, foreskin characteristics and other quality characteristics.

Extraction of Monoglycerides by Molecular Distillation

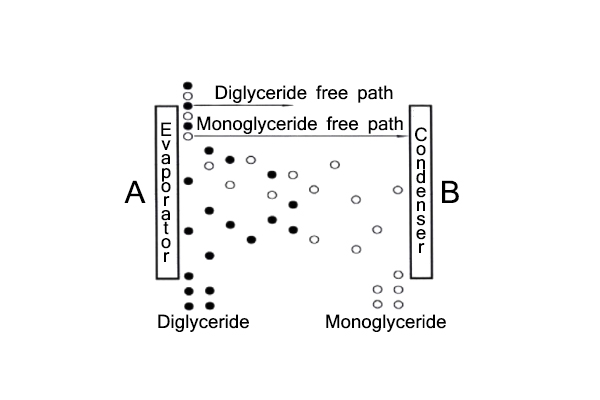

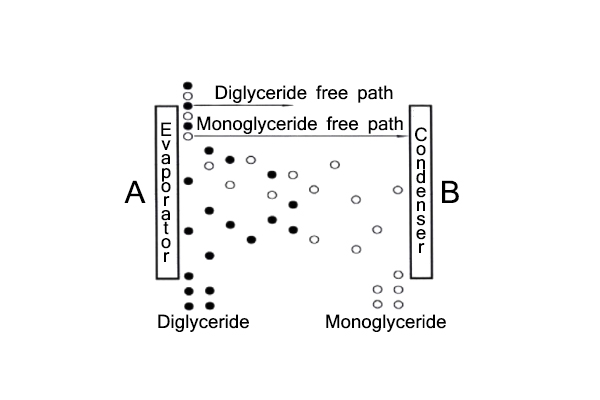

The molecular distillation technology can greatly increase the monoglyceride content of this emulsifier. The molecular distillation principle is based on the fact that the average free path of different types of molecules is different. Molecules are subject to a large binding force in the liquid state. When sufficient energy is obtained, the binding force can be overcome to become a gaseous molecule. The linear distance that the molecule does not collide with other molecules after it escapes the liquid surface is called the molecular free path. Different types of molecules have different molecular free paths under the same external conditions. Even if the same molecule has different molecular free paths at different times, the average value is called the average molecular free path. The average free path of the heavy molecules in the gas phase is small, and the average free path of the light molecules in the gas phase is large. If the condensation surface is set at a position where the liquid surface is larger than the average free path of the heavy molecules and smaller than the average free path of the light molecules, the light molecules can fly The condensing surface is condensed and fractionated, and heavy molecules fail to reach the condensing surface and collide with each other to return to the original liquid surface to achieve the separation of the mixture. Molecular distillation technology has the characteristics that the distillation temperature is lower than the boiling point of the material, the distillation pressure drop is small, the heating time is short, and the degree of separation is high. It is suitable for separating high molecular weight, high boiling point, and heat-sensitive substances. Monoglyceride is the most successful example.

During distillation, the mixture (mono- and di-glycerides) flows downward by gravity and mechanical force and forms a fast-moving, uniform-thickness film that is heated on the wall of the evaporator, molecules with sufficient energy overflow the liquid surface and evaporate, and gaseous heavy molecules (double-glyceride) Ester) has a small mean free path, fails to reach the condenser and returns to the wall of the evaporator after multiple collisions, and flows out of evaporator A. The average free path of gaseous light molecules (monoglycerides) is large and the distance traveled is long. It can directly reach the condenser to be condensed into a liquid and flow out from condenser B to complete the separation process to obtain a product with a monoglyceride content of 90% or more. One molecule of distilled monoglyceride.

Monoglyceride molding

According to different customer requirements and different product uses, the molecularly distilled monoglycerides are spray-dried, beaded, or agglomerated into various forms: powder, bead, and block.