-

WhatsApp

-

Email

Equipment for cannabis extraction - closed loop extraction equipment

Although cannabis concentrates have been around for some time, they are becoming increasingly popular in the United States. This is due to the legalization of cannabis in several states, including Colorado, Washington, and can be obtained by using different extraction methods. These extraction methods are usually performed using special solvents and extractants (such as propane, ice water, butane, etc.) to isolate some beneficial products from Trichomonas in cannabis plants. The methods of extracting cannabis are different, and some significant changes have been made to them over time, and it has only recently been discovered that closed-loop methods are preferable to other methods.

Closed loop methods are chemical extraction systems used to make cannabis concentrates. The closed-loop extraction process involves coating the raw hemp plant in a pressurized solvent and exposing it to high pressure shocks, which reduces it to a resin before further processing into the desired form of hemp concentrate. These concentrates include active resins containing the most active terpenes and butane hash oil, which are often further processed into products such as buds, crushed, wax and crushed.

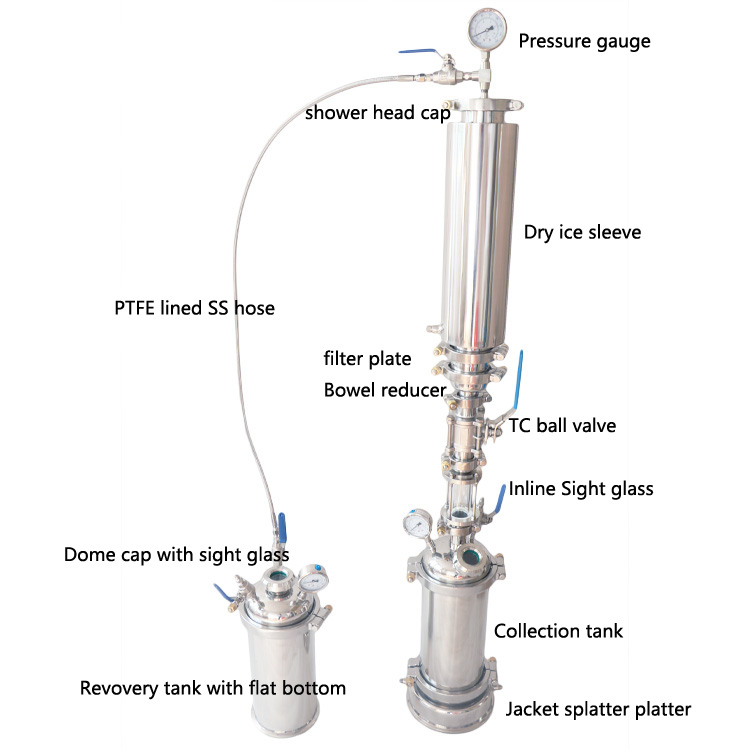

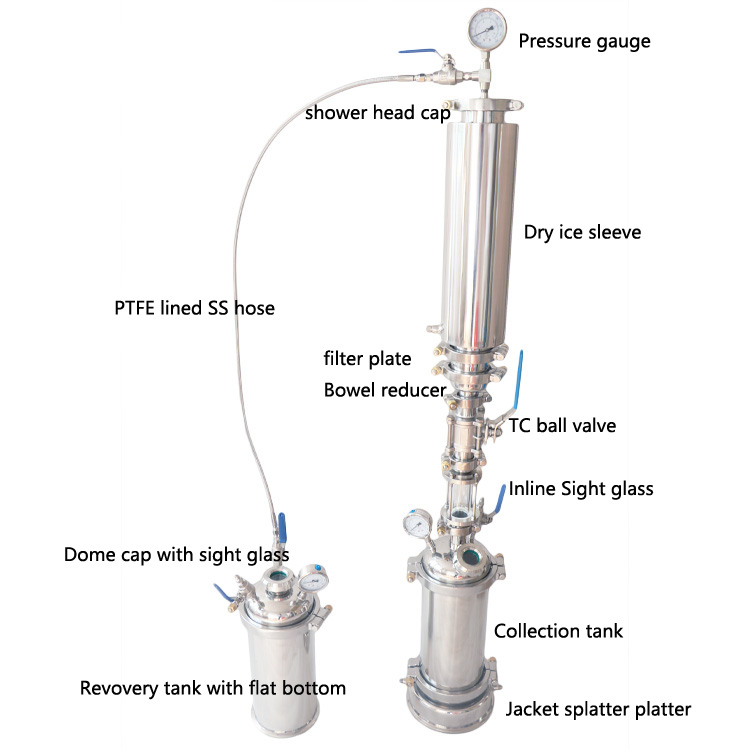

The main feature of the closed-loop extraction system is to isolate the air from the solvent during the extraction process, which is the difference between it and the ring-open method. The system is a professional setup consisting of several devices, such as a solvent storage tank, a recovery tank, a scale and several pumps. The system includes a continuous check of pressure and valve operation, and also allows reuse of solvents.

Although closed-loop extraction technology has been used for many years to produce perfumes, beauty products, food additives, and other essential oils, it has only recently been discovered that it is safer than open shot peening and closed-loop systems before it became a popular method of cannabis extraction. Because it minimizes the risk of explosion and provides a safer way to use flammable solvents. There is no opening in the machine used for extraction, so the solvent cannot be safely contained, and no gas is allowed to escape.

In order to achieve closed-loop extraction, some equipment and devices are needed. These equipment and devices are very important for forming an efficient extraction system. These include: pressurized solvent tanks, pressurized pumps, blasting chambers, collection chambers, vacuum furnaces, and recovery pumps.

After extraction, the obtained concentrate can be converted into different products, and the methods used may vary depending on the products made. The concentration of cannabinol CBD concentrate in the closed-loop system is usually very high, reaching about 80-90%.

Advantages of closed-loop extraction

Closed-loop extraction systems have several advantages, which is one of the reasons why they are more popular than open-loop extraction systems, some of which are listed below.

Safety

Compared to other methods, the closed-loop method is a very safe extraction method because it minimizes the risk of explosion. The escape of gases and solvents through vents can cause an explosion, so the sealing of solvents and air reduces the possibility of such escapes. Although, it is important to have proper ventilation during extraction to ensure complete safety.

effectiveness

The ability to fully control the closed-loop system makes it more efficient because it prevents the loss of any pressure, which can further establish pressure and maintain consistency to ensure effective pumping.

Cost-effectiveness

Sealed closed-loop systems allow you to control them and prevent the escape of chemical solvents. As a result, the solvent can be reused later, making the extraction method economical and cost-effective.

Better quality

Closed-loop extraction systems provide some of the best quality products. The increased temperature and pressure balance present in the system produces very pure, rich and delicious concentrates. Compared to open-loop extraction systems, the closed-loop extraction process does not leave any residues from solvents or other impurities because everything is sucked out of the vacuum, resulting in cleaner concentrate

Powerful closed-loop extraction system

As a truly closed system, all extraction and solvent recovery processes are operated within the confines of the coded and rated tanks and lines. In this new solvation extraction process whereby the plant material is saturated with an adequate volume of a chosen solvent until all the target chemical compounds are dissolved at which time they are carried away from the plant matter using a specific flat micron size filter. When the plant matter is filtered away and the solvent is recovered for reuse using a passive process in a closed system, the process is completed.

The system is not only safer, but faster because its tanks hold all the solvent and a complete extraction could be performed in a single pass. This larger solvent tank allows much faster extraction speeds as well as being able to hold all the required solvent that allows much greater control over the contact time, contact temperature, contact pressure, and polarity of the solvent as it passes through the plant material. As the density of the plant material column can be increased as well, the production per extraction is increased as well. In that case, more plant matter could be extracted in a smaller extractor.

This design of the extractor not only facilitates all the above-mentioned features but also allows the greatest degree of adjustment to the maximum number of controls.

Complete Accessory ist of 1LB Closed Loop extractor

|

4" end cap with 1/4" MNPT and spray ball

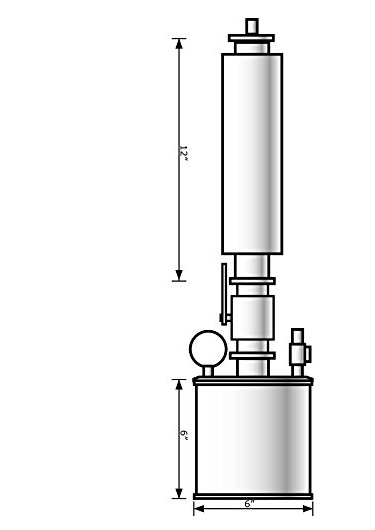

4" x 24" full jacketed spool with outer sleeve 6"x21"

4" Tri-clamp Filter Plate

4" to 1½" cone reduce with 1/4”MNPT

1½" 3pcs clamp ball valve

1½" short inline sight glass

10" end cap with 1pc 1/4" MNPT ,1pc 1/4" FNPT,

1pcs 1.5" tri-clamp ferrule in centre, 2pc sight glass

10"x10" spool

10"x2" Jacketed splatter platter

10" end cap with 1pc 1/4" MNPT and union sight glass

10"x10" spool with weld end

10" high pressure clamp with seal

3" high pressure clamp with seal

1½" high pressure clamp with seal

1/4" small ball valve

|