-

WhatsApp

-

Email

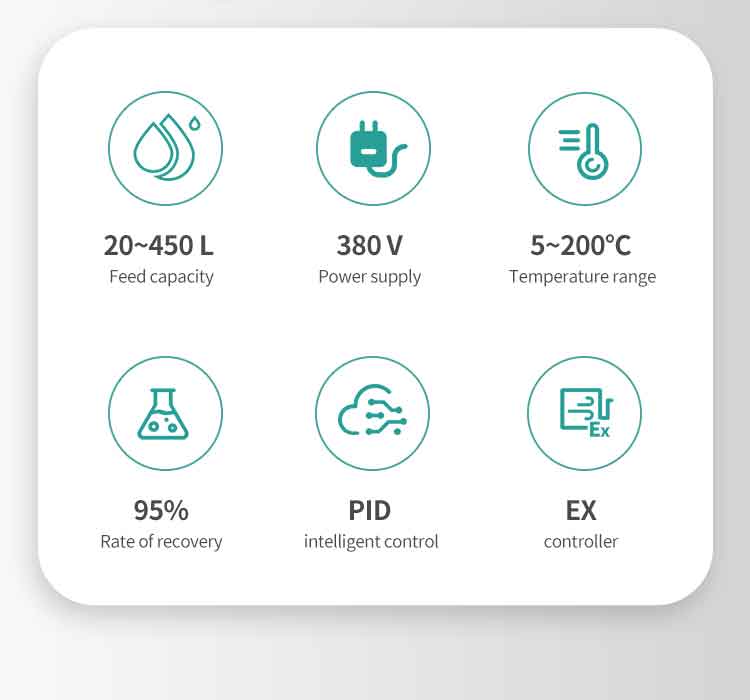

The solvent recover recycling machine for sale uses the principle of distillation: this equipment adopts the principle of distillation and separation, and the used organic solvent is recovered and processed to regenerate and recycle the waste organic solvent. (The equipment is restored to a new solvent and put into the production process again to achieve multiple recycling of the solvent to save costs and achieve the purpose of environmentally friendly production.)

Simple operation: no need for special personnel to operate, employees only need to add materials, turn on the power, and clean up. The residue is enough, and the whole process is automatically recycled and automatically shut down; saving human resources. The quality of the solvent after recovery is as good as new: because the equipment adopts the principle of distillation and separation, no chemical components are added, and the chemical characteristics of the solvent will not be changed in the slightest.

The solvent recover recycling machine price can recover all kinds of industrial waste organic solvents, such as Tianna water, white oil, dichloromethane, hydrocarbon cleaning agent, NMP, etc. Customers can choose a standard solvent recover recycling machine suppliers, or according to the type of solvent to be recovered Customized customized solvent recovery machine and recycling requirements, Kuanbao brand solvent recover recycling machines manufacturer, the whole machine and components are designed with explosion-proof safety, and the product has passed the test and certification of China National Explosion-proof Electrical Product Quality Supervision and Inspection Center.

The solvent recovery machine has the following characteristics:

1. All electronic control systems and components are explosion-proof structures such as: explosion-proof electric control box, explosion-proof heater, explosion-proof condensing fan, etc. The explosion-proof electric control system is made of cast aluminum material, fully sealed explosion-proof design, to prevent sparks from contacting the container.

2. The thermometer has no electrical contacts and will not produce sparks.

3. All cable joints are fully explosion-proof sealed design, using stainless steel pipe as protective material, will not be corroded and ensure safety.

4. The recycling bucket adopts stainless steel, double-layer structure, interval heating, reinforced bucket cover design, accurate temperature control, explosion-proof and leak-proof.

Do not throw away the waste solvent used in the factory, do a good job in the recycling of waste solvent, reduce the cost of the enterprise, improve the efficiency, and reduce the environmental damage.

In order to obtain better maintenance effect, different solvent recover recycling machine for sale should be used when recovering different solvents. If the solvent recover recycling machine price maintains a good cleaning and working order, it will save a lot of adjustment and cleaning time during recovery.

1. When the solvent recover recycling machine suppliers stops working, please turn off the power supply, and turn off the gas source with a vacuum pump;

2. Keep the body of the solvent recovery machine clean and the site hygienic, and keep the space for solvent processing ventilated.

3. Lubricate the key parts of the solvent recover recycling machines manufacturer after work every day. Due to normal inter-fitting wear and aging, seals, springs, needle valves and nozzles must be replaced regularly. Replacement should follow the solvent recovery machine manufacturer's instructions. Since excess oil will flow into the paint and oil passages, causing recycling defects, great care must be taken during lubrication, and the mixing of oil and paint will reduce the quality of recycling. Do not soak the solvent recover recycling machine price in the cleaning solution for a long time, which will harden the sealing ring and destroy the lubrication effect.

Common usage requirements for solvent recovery machines.

1. The workplace is well ventilated;

2. The temperature of the workplace cannot be higher than 45 degrees;

3. There should be no sparks or open flames in the workplace;

4. Within a radius of 10 meters of the workplace, no violent collisions can occur;

5. The solvent recover recycling machine for sale is prohibited from being exposed to direct sunlight or rain;

6. It is forbidden to use plastic buckets to store solvents;

7. If there are conditions, please use explosion-proof lighting;

8. Do not open the lid of the recycling bin while the equipment is running;

9. After the equipment is used, the residue and foreign matter in the recycling bucket must be cleaned up before the next round of recycling;

10. In case of equipment failure, please contact the manufacturer in time, and unauthorized maintenance is prohibited;

How can the solvent recover recycling machine suppliers be better debugged during use?

1. Check steam lines for blockages or leaks. The method of pipeline inspection: turn off the main power switch, loosen the locking handle of the barrel cover, open the barrel cover, and blow 0.2Bar compressed air into the barrel from the solvent outlet outside the barrel; confirm that the air can be smoothly discharged from the barrel. The solvent outlet pipe in the barrel is blown out.

2. Whether the lid gasket is sealed and leak-free. Inspection method: blow 0.2Bar of compressed air into the barrel from the solvent outlet outside the barrel; apply soapy water to the edge of the barrel lid; if there is continuous and even bubbling and the bubbles are not broken, the seal is good, otherwise there is leakage.

3. Start-up inspection: Check to confirm that the fan is running normally and the heater is heating normally.

4. The machine is initially set according to the boiling point and characteristics of the solvent to be recovered.

Pre-sale Service:

--24 Hours online service for your consult.

--Help choose right model,and a series of service,person,advise.

--Give you best offer.

--Provide discount for many sets order.

--Do customer's request.

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

After-sale service:

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Remote control technical consult.

--Free installation DVD.

--Maintenance plan.

Packaging:

-After use cartons inside, outside with wooden case packaging;

-Both neutral and customized packaging can be available.

Shipping:

-We can ship the goods to you by International Express such as DHL, TNT, EMS, FedEx and so on and you can also choose the appropriate one based on your timeline and budget. Besides, you can definitely choose to use your own shipping agent.

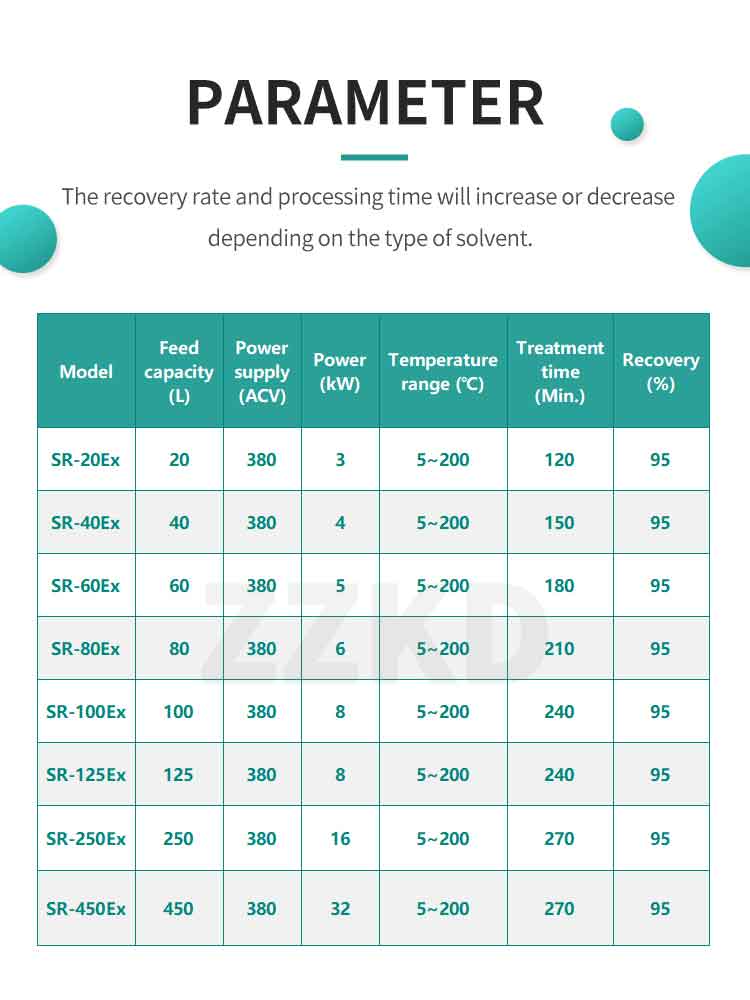

| Model |

Feed capacity (L) |

Power supply (ACV) |

Power (kW) |

Temperature range (℃) |

Treatment time (Min.) |

Recovery (%) |

| SR-20Ex | 20 | 380 | 3 | 5~200 | 120 | 95 |

| SR-40Ex | 40 | 380 | 4 | 5~200 | 150 | 95 |

| SR-60Ex | 60 | 380 | 5 | 5~200 | 180 | 95 |

| SR-80Ex | 80 | 380 | 6 | 5~200 | 210 | 95 |

| SR-100Ex | 100 | 380 | 8 | 5~200 | 240 | 95 |

| SR-125Ex | 125 | 380 | 8 | 5~200 | 240 | 95 |

| SR-250Ex | 250 | 380 | 16 | 5~200 | 270 | 95 |

| SR-450Ex | 450 | 380 | 32 | 5~200 | 270 | 95 |

1.What's the minimum order quantity?

One set at present.

2.What kind of payment term do you accept?

Normally we accept TT, Paypal, Western Union, Alibaba Escrow, and L/C. The exactly term will be discussed during the deal.

3. How will you delivery these goods?

It will be decided according to your quantity. Normally we will choose International Express, Air and sea.

4.How will package glass equipment?

We package these glass equipment in good and Non fumigation standard wooden case.

5.Can you accept OEM terms?

Sure.

6.How to choose suitable equipment ?

You tell us your requirements (For example: capacity, temperature range, pressure, etc ), we will recommend you the best suitable equipment.