-

WhatsApp

-

Email

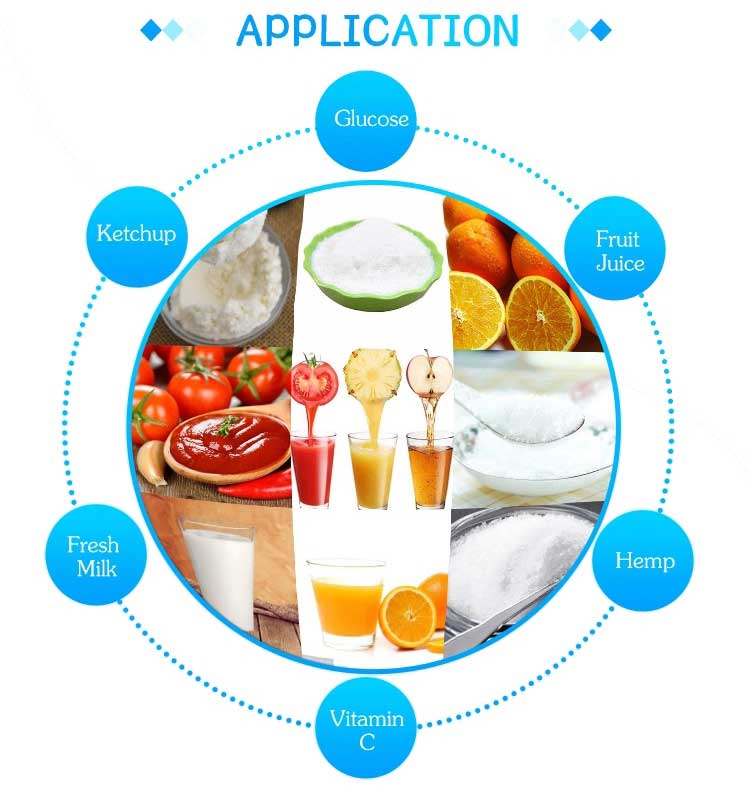

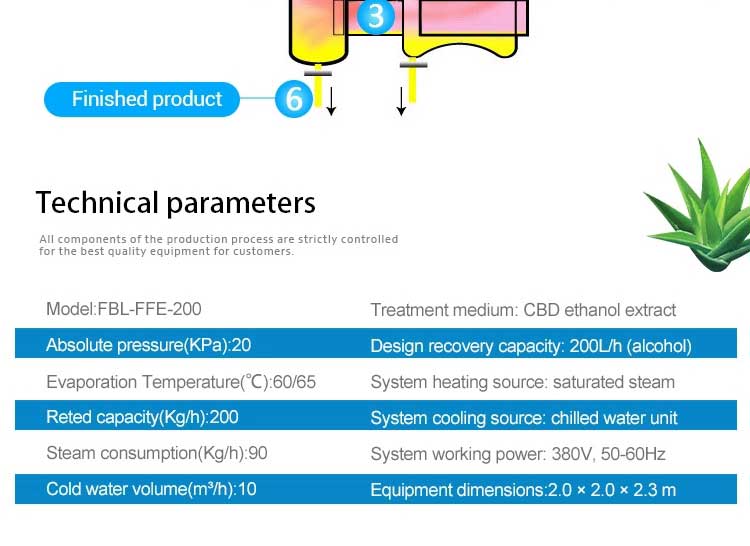

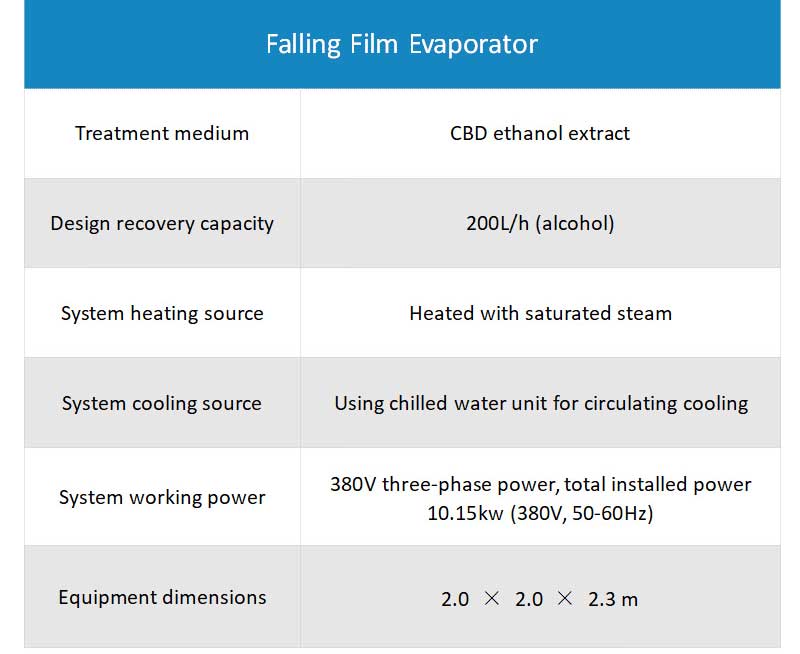

The falling film evaporator is suitable for the concentration of heat-sensitive materials such as fresh milk, fruit juice, soy milk, xylitol, sorbitol, Vc, honey, starch sugar, fructose, glucose, and traditional Chinese medicine extracts. The equipment operates in a vacuum state, the materials evaporate at a low temperature, and the heating time is short. It can maintain the original flavor of the materials to the maximum extent and continuously enter and exit the materials. It is easy to operate, maintain and clean.

Falling film evaporator can be divided into 2 effects, 3 effects, 4 effects falling film. The higher the level, the larger the processing capacity, and the higher the price of the falling film evaporator. The falling film evaporator CBD is made of stainless steel, which complies with GMP specifications and can be used for food-grade production.

Features

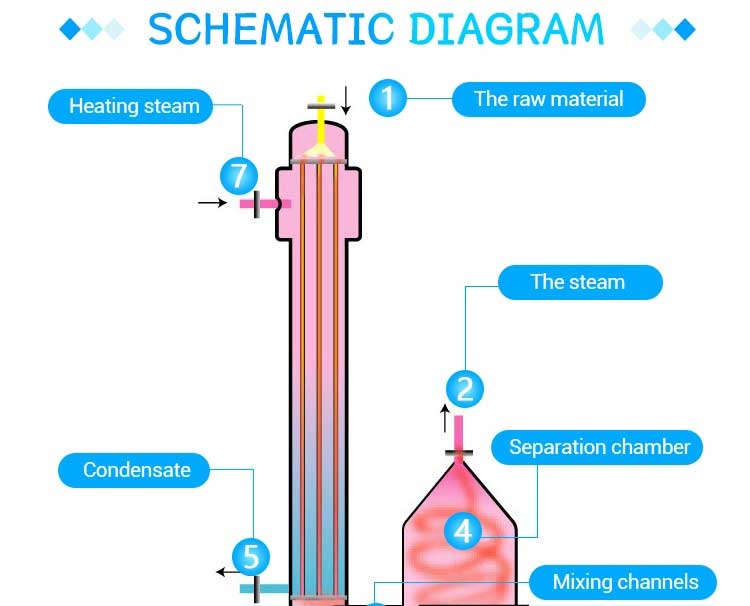

- The feed liquid of the falling film evaporator is added from the top of the evaporator, and it forms a film along the tube wall under the action of gravity. In the process, it is concentrated by evaporation and a concentrated liquid is obtained at the bottom. Falling film evaporator can evaporate materials with higher concentration and viscosity.

- Since the solution flows in a film in a single- pass evaporator, the heat transfer coefficient is high.

- Short residence time, not easy to cause material deterioration, suitable for handling heat sensitive materials.

-The liquid retention is small, and the falling film evaporator can adopt fast operation according to changes in energy supply, vacuum degree, feed amount, concentration, etc.

- Since the process fluid flows only by gravity, rather than being driven by high temperature differences, low temperature difference evaporation can be used.

- Falling film evaporator is suitable for evaporation and concentration of foamable materials.Because the material liquid is evaporated into a film in the heating tube, that is, gas-liquid separation is formed.At the same time, at the bottom, most of the material liquid is pumped away, and only a small part of the material liquid and the secondary steam enter the separator to strengthen the separation.

Detail

Supporting equipment for falling film evaporator:

- Industrial chiller- Electric steam generator

After sale

Package

Transport

1. What should pay attention to during the use of falling film evaporator?

-Please read the operation manual carefully before operation.-Non-professional operations are prohibited.

-The equipment power is 480v AC and the full load power is about 6kW.

-Operate the equipment in the correct order.

-It is forbidden to perform maintenance and disassembly of electrical components without disconnecting the power supply, and non-professional operations are strictly prohibited.

-Regularly check the wiring in the cabinet to prevent the end of the wire from falling off and the wiring from aging.

-Unauthorized modification or use of non-recommended spare parts without the manufacturer's permission may cause fire, electric shock, and other accidents.

-Before starting the equipment for electrical operation, confirm the status of the system equipment.