-

WhatsApp

-

Email

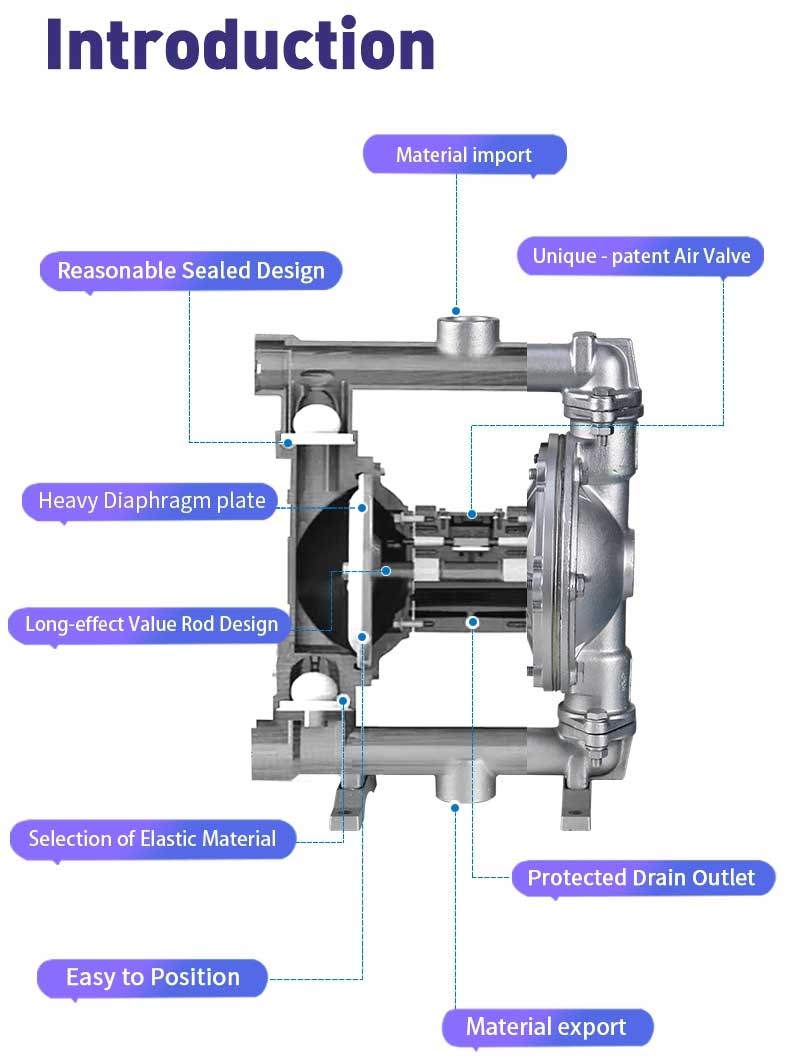

The pneumatic double diaphragm pump is one of the most durable, non-lubricated air valves. Diaphragm pumps are ideal for applications requiring high flow rates and portability. A variety of food-grade elastomers are available, including Santoprene, PTFE, and overmolded EPDM / PTFE.

Features

- Idling ,Self-priming , Submerse capability.

- Provide stall-free, ice-free zero leak operation.

- Epoxy-coated air section for tough environmental conditions.

- Low shear force , not easy to damage the material structure.

- Bolt joint design provides even sealing pressure for optimal performance

- Modular air valve,low pulsation operation,providing smooth and rapid changeover.

- No electricity . It's safe and realiable while using in the flammable and explor place .

- Diversity of material,no rotating parts,applicable to various erosive situations.

- Can pump corrosive , volatile, flammable, poisonous fluids with particles and high viscosity.

- Delivery lift and flow can pass the pneumatic valve open to realize the stepless adjustment.

Detail

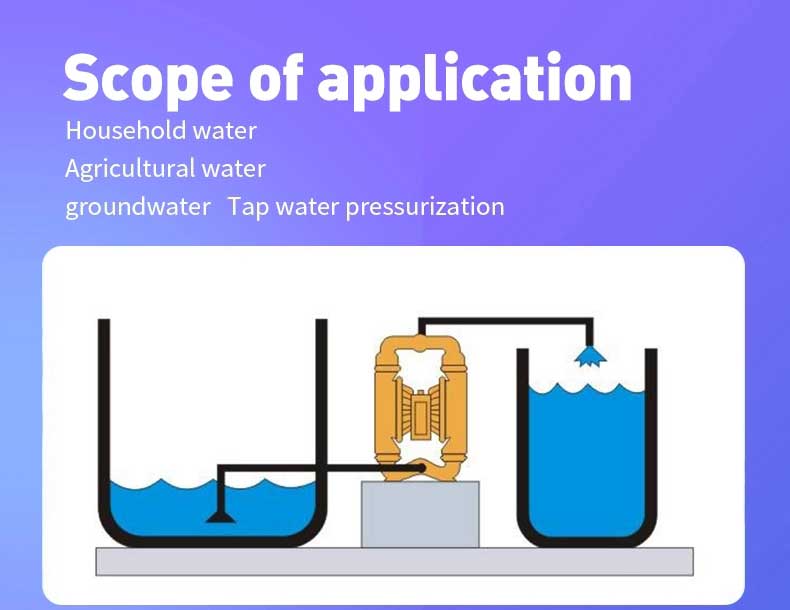

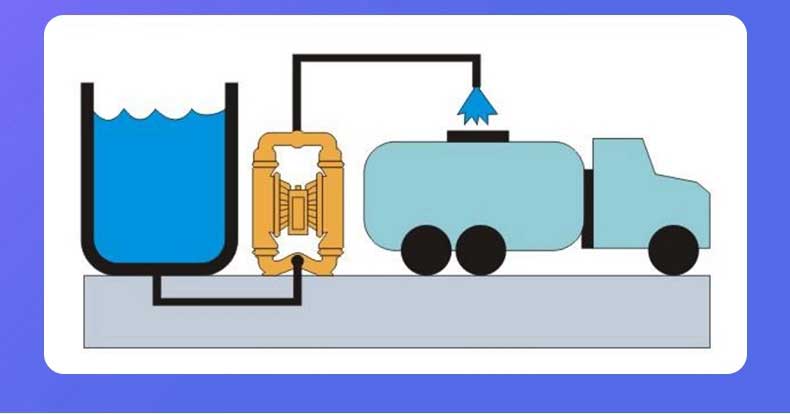

KDDP-Q-25 diaphragm vacuum pump is mainly used in the following areas:

The diaphragm pumps can be applied to ship/bus/train unloading, chemical production, batch treatment and mixing, large tank or tank area conveying, common feed-conveying, system flushing, wastewater treatment or fluid filtration, packaging or filling, recycling and recycling.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. What media can the pneumatic diaphragm pump convey?

- Pumps peanut butter, pickles, mashed potatoes, small red intestines, jam apple milk, chocolate, etc.- Pumping paint, gum, pigments.

- All types of adhesives and glues can be pumped.

- Variety of tile, porcelain, brick and pottery glaze.

- After the well is drilled, pump the sediment and grout.

- Pumps various emulsifiers and fillers.

- Pump all kinds of sewage.

- Use pumps as tankers and barges to clear the warehouse to absorb the sewage in the warehouse.

- Hops and baking powder slurry, syrup, molasses.

- Pumping up water in mines, tunnels, tunnels, beneficiation and slag.

- Pumping cement grout and mortar, various rubber slurry.

- Various abrasives, corrosives, petroleum and mud, cleaning grease and general containers.

- Various highly toxic, flammable and volatile liquids.

- All kinds of strong acid, strong alkali, strong corrosive liquid.

- Various high temperature liquids can withstand up to 150 degrees.

- Used as a pre-pressure feeding device for various solid-liquid separation equipment.

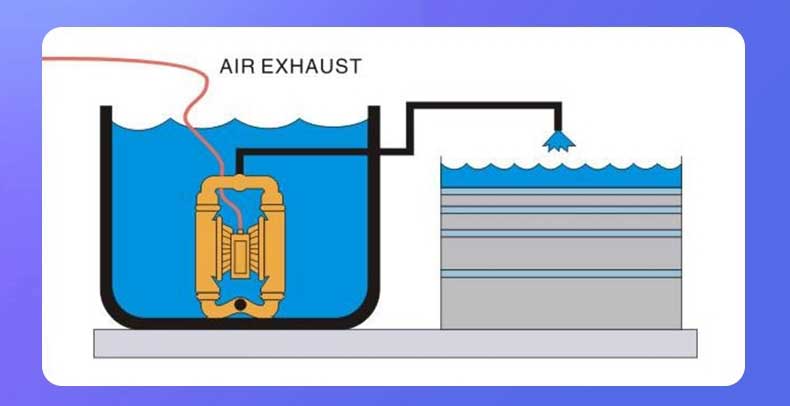

2. How is the pneumatic diaphragm pump inflated?

The structure of the diaphragm pump air chamber is generally used to separate the water chamber from the air chamber. After filling the air chamber with compressed air, the pulsation of water in the water chamber is absorbed by the compressed air in the air chamber through the rubber diaphragm. The role of the air chamber is to use the compressibility (or elasticity) of the air to absorb the pulsation of the water from the diaphragm pump and make it stable. The water flow into the system is basically smooth. However, in order to meet the requirements of basically stable water flow, the air pressure in the gas chamber should be adapted to the water pressure.Diaphragm pump air chamber inflation method: Before the diaphragm pump runs, inflate the air chamber first, and its air pressure is greater than the working pressure of the pump. Drive the diaphragm pump and adjust it to the working pressure. At this time, you can see that the hose of the pump's outlet shakes violently. Take a needle and deflate at the air nozzle. As the deflation progresses, the jitter of the water outlet hose will gradually disappear. After the water outlet hose is stable, stop deflating.