-

WhatsApp

-

Email

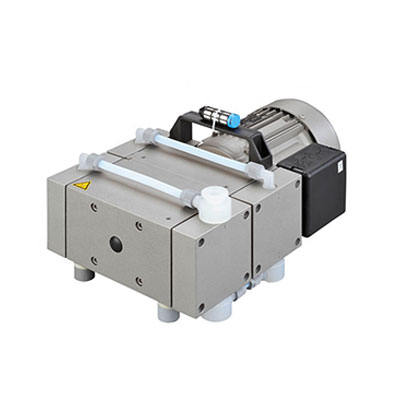

P20 series corrosion-resistant vacuum diaphragm pump is a two-stage pump with medium gas. All parts in contact with gas are PTFE materials. It has high corrosion resistance and a wide application range. It is suitable for chemical, pharmaceutical, petrochemical, and other industries. Treatment of corrosive gases, such as suction filtration, vacuum distillation, rotary evaporation, vacuum concentration, centrifugal concentration, solid-phase extraction, and the like.

Features

- Vacuum stable and easy to control

- Complete chemical resistance

- No water consumption, strong environmental performance

- Small size and lightweight

- Easy to use, clean

- Durable and stable work

- Easy maintenance and repair

Detail

The P20 diaphragm vacuum pump is suitable for vacuum equipment used in which equipment:

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | P20 | |

| Voltage | 110V | 220V |

| Power | 130W | 120W |

| Pump head type | Two-stage | |

|

Ultimate vacuum degree |

8mbar | |

| Operate pressure | 1bar(Max.) | |

| Flow | 20L/min | |

| Interface | 10mm | |

|

Medium and ambient temperature |

5~40ºC | |

| Pump head | PTFE | |

| Diaphragm | PTFE coated | |

| Valves | FKM or FFPM | |

| Rotating speed | 1400rpm | |

| Humidity | <80% | |

| Dimension | 315*165*210mm | |

| Weight | 9.6kg | |

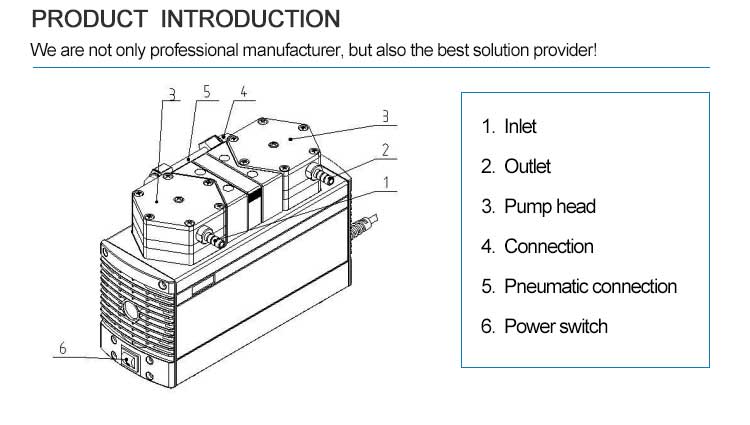

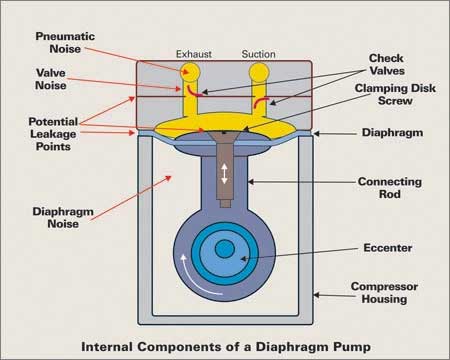

1. Steps for installing the diaphragm pump

A. Before disassembling the diaphragm pump, mark the pump body and the air chamber on the left and right sides of the diaphragm pump respectively to facilitate subsequent reassembly operations.B. Use a wrench to loosen the screw connecting the outlet pipe and the pump body. Remove the outlet pipe to see the ball and seat. Take out the ball and seat and check other spare parts of the pump. Check carefully for wear and chemical corrosion. Cracks and other phenomena.

C. Use a wrench to separate the outer pump body from the intermediate body of the internal test pump. After removing the pump body, the diaphragm and diaphragm clamp can be seen.

D. Use tools or wrenches to secure the left and right edges of the diaphragm outer splint to separate the diaphragm assembly from the intermediate body. Then turn the diaphragm device clockwise to release. After removing the outer splint of the membrane, the shaft was removed from the intermediate body.

E. Use a clamp (padded wood) to separate the shaft from the diaphragm unit and inspect the shaft, splint, and diaphragm for damage and corrosion.

F. The installation is sequentially performed from step E to step A.