-

WhatsApp

-

Email

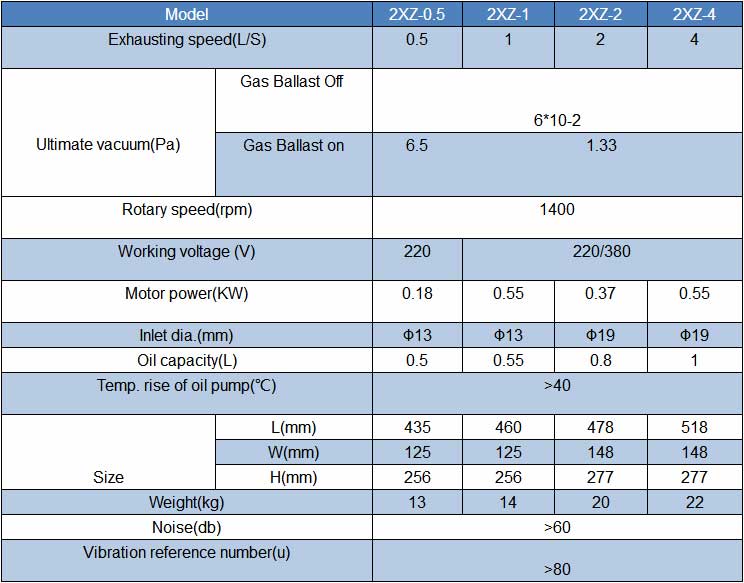

2XZ - 2 series rotary vane vacuum pump is a two-stage high-speed direct-drive rotary vane vacuum pump (in the following called “the pump” for short). Its working principle is the same as the 2XZ type pump. Rotors are eccentrically mounted within the cylindrical housing of the stators and vanes are fitted freely inside the respective slots of the rotor.

2XZ - 2 rotary vane vacuum pump has a speed of 1400 (rpm). Suitable for glass reactors, rotary evaporators, short-path distillation, molecular distillation, vacuum drying ovens, and other equipment.

Features

- The 2XZ series rotary vane vacuum pump is a two-stage direct connection rotary vane vacuum pump that can be used for drying, sealing containers and other auxiliary suction or vacuum equipment.

- It has the advantages of small size, lightweight, low noise, convenient for using and more.

- 2XZ series rotary vane vacuum pump can not be used as compression pump.

- The 2XZ series rotary vane vacuum pump can be used alone or as a pre-pump for the ba booster pump, diffusion pump, molecular pump and titanium pump. Also used in the production of electronic equipment, vacuum drying, filtration, welding, metal smelting and so on.

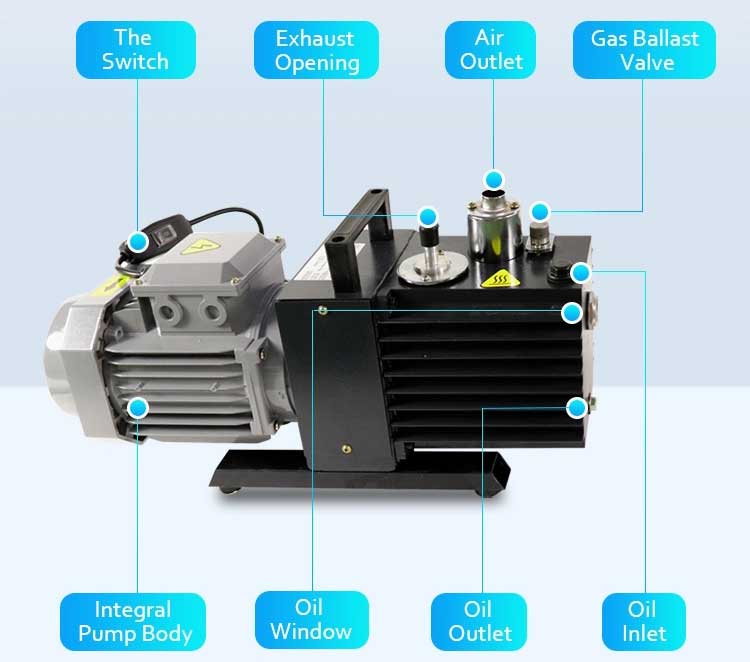

Detail

The rotary vane vacuum pump is suitable for the vacuum equipment of which equipment:

Short-path distillation kit

Freeze dryer

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1.How to change the oil of the 2XZ rotary vane vacuum pump?

Let the pump operate about 1/2 hr to raise the temperature of the oil as to decrease the viscosity of the oil, stop the pump and drain out the oil. Restart the pump and let it operate about 1-2 minutes with inlet port widely opened. In this interval slowly fill the little amount of clean oil into the pump through the inlet port to replace the oil originally in the pump housing.

2.Rotary vane vacuum pump precautions

It is forbidden to mix diesel, gasoline and other oils with higher saturated vapour pressure with vacuum oil to avoid damage to their ultimate vacuum. Wipe the parts to be cleaned with a cotton cloth.

3.Rotary vane vacuum pump removal steps:

(1)Drain oil.(2)Screw out the bolts on the inlet flange, take out the inlet pipe. Screw out the bolts on gas-ballast flange, take out the gas ballast valve.

(3)Take off the oil box.

(4)Take off the split-pin on the oil check valve and the impeller to the check valve.

(5)Screw out the tighten bolts of the frame and pump body, take off the pump body.

(6)Screw out the cover plate bolts, take off the cover and then pull out the two, rotors and their respective vanes.