-

WhatsApp

-

Email

The factory price sells RE-2000 rotary evaporator (2L), which can be used for concentration, crystallization, drying, separation and other experiments. The collected and dissolved steam is recovered by effective glass condenser cooling to increase evaporation efficiency. Enhanced purification of biological products, especially suitable for pyrolysis and deterioration.

Features

- Quick and easy lifting mechanism.

- The evaporators can incline willfully along the horizontal direction within 0-45°.

- High evaporation rate vertical condensation system.

- Heating Tank.

Stainless steel heating tube provides heat source. The temperature range will be RT~99 ℃ with water. The water tank is cylindrical and made of high quality stainless steel. So it is corrosion resistance and durable. The tanks are available for 2-20liter rotating flask heated. Moreover, the tank can be moved according the rotating flask size.

- Vacuum Sealing.

PTFE evaporating pipe, good sealing and heat-resisting. Joint part is sealed Fluorine rubber mat which brings good performance.

- Automatic Temperature Control Digital Display.

Temperature digital display and control by pt100 sensor. when the pre-selected temperature is reached the temperature you setted, the controller automatically will turn off the heater supply, When it is lower than the pre-selected temperature, controller will switch on automatically to realize constant temperature.

- Rotating flask and Collection flask.

The flasks are made of GG-17 high borosilicate glass which is blowed by hand. Their intensity, concentricity, glossiness, and surface finish are better than rough flasks.

Detail

For the perfect use of the entire rotary evaporator system you may need the following equipment

- Low temperature constant temperature reaction bath

- Circulating cooler

- Constant temperature circulator

- Low temperature circulation pump

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | RE-2000A | RE-2000B | RE-2000E |

| Evaporating Flask(L) | 2L 29#conical Ground Joint | ||

|

Receiving Flask(L) |

1L Ball Grinding Mouth | ||

| Motor Power(W) | 40 | ||

| Lifting Mode | Motor Automatic Lifting | ||

| Rotating Speed(R/min) | No Polar 0-120 | Digital Display 0-120 | LCD 0-120 |

| Lifting Height(mm) | 0-140 | ||

| Water Bath Power(KW) | 1.5 | ||

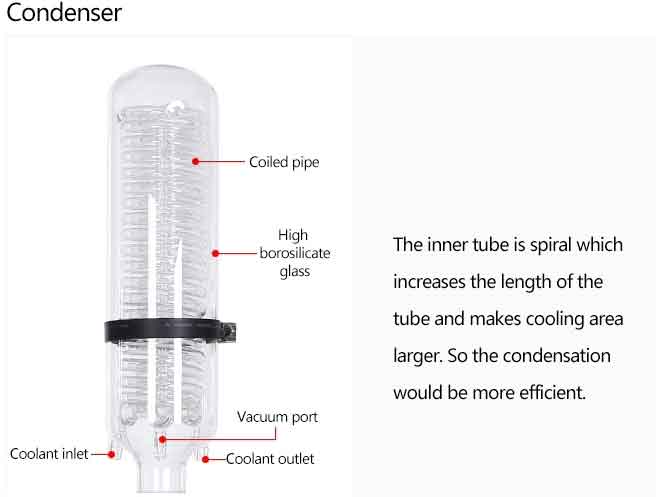

| Condenser | The double backflow integration standard condenser | ||

| Voltage(V/Hz) | 220 50/60 | ||

| Bath Temp Control Range(℃) | RT-99 | ||

| Water Bath Size(mm) | Φ230*130 | ||

| Evaporation Rage(L/H) | ≥1 | ||

| Extemal Size(mm) | 550*420*780 | ||

| Note | Customized configuration is available | ||

1. What are the requirements for the selection of cryogenic cooling equipment for the RE-2000 rotary evaporator?

For the cryogenic cooling equipment of the rotary evaporator, it is recommended to select the DLSB-5/10 model low temperature coolant circulating pump produced by our company. The cooling capacity of this model is 5L and the minimum temperature is -15 °C. Our RE-2000 rotary evaporator has a rotating bottle capacity of 1~2L, so the DLSB-5/10 cryogenic coolant circulation pump is fully suitable for the RE-2000 rotary evaporator.

2. What kind of glass is used in the RE-2000 rotary evaporator?

It is made of borosilicate glass, which has good heat resistance and shock resistance. It is durable and durable. It is easy to clean. The heat resistant temperature can reach 400 °C, and the temperature tolerance range is 120 °C.

3. How will you deliver these goods?

It will be decided based on your quantity. Usually we will choose international express, air and sea.

4. Can the RE-2000 rotary evaporator use a vertical circulating water vacuum pump?

Of course, but we recommend you use a benchtop circulating water vacuum pump. Because the RE-2000 Rotary Evaporator is a small-capacity rotary evaporator unit, the bench-top circulating water vacuum pump can be used to keep the entire system running, saving you equipment costs. If you have other needs, you can of course choose to use the vertical circulating water vacuum pump without any problems.