-

WhatsApp

-

Email

The 1L jacketed glass reactor is a laboratory glass reactor made of borosilicate glass and 304 stainless steel. Has high temperature, corrosion, easy to operate, easy to maintain and so on.

Features

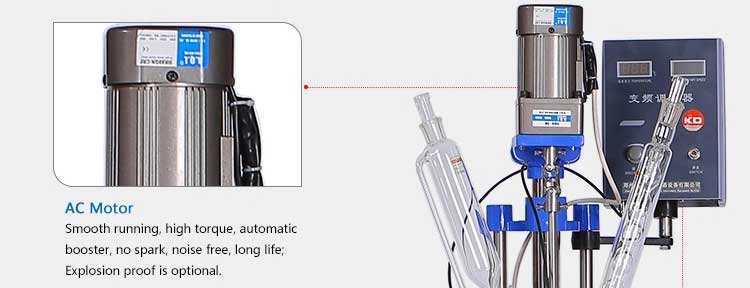

- It adopts AC frequency control of motor speed So the rev is steady , no spark appear,wide moment, safe, and can be used as the constant working.

- All sets of glass apparatus are made up of GG17 or GG33 with the double-layer jacketed structure. The thickness of the glass is 5-7 mm with good chemical and physical properties.

- The teflon components sealing method makes it in a state of high vacuum ,anti-acid and anti-alkali.

- It can work under the ordinary pressure and negative pressure and can reach the -0.098Mpa positive pressure.

- Constant temperature and numerical control oil bath pan, with beautiful and anti-corruption stainless steel inner tube ,is controlled by the micro-computer which makes it work accurately, low fluctuation and conveniently.

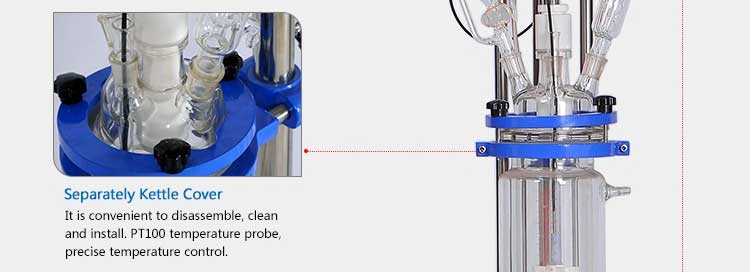

- The drain hole contains the flange mouth and the PTFE drain valve which leave no dead angle and rudimental material. The whole set of drain valves can be easily demounted and the inside reactor can be cleared conveniently.

- All sets of glass apparatus are made up of GG17 or GG33 with the double-layer jacketed structure. The thickness of the glass is 5-7 mm with good chemical and physical properties.

- The teflon components sealing method makes it in a state of high vacuum ,anti-acid and anti-alkali.

- It can work under the ordinary pressure and negative pressure and can reach the -0.098Mpa positive pressure.

- Constant temperature and numerical control oil bath pan, with beautiful and anti-corruption stainless steel inner tube ,is controlled by the micro-computer which makes it work accurately, low fluctuation and conveniently.

- The drain hole contains the flange mouth and the PTFE drain valve which leave no dead angle and rudimental material. The whole set of drain valves can be easily demounted and the inside reactor can be cleared conveniently.

Detail

For the perfect use of the entire glass reactor system you may need the following equipment

- High and low-temperature machine

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | S-1L Jacketed Glass Reactor |

| Stirring Power(W) | 60 |

| Stirring Speed(rpm) | 0~600(max.1300) |

| Stirring Shaft Diameter(mm) | 12 |

| Reaction Flask Capacity(L) | 1 |

| Voltage(V/Hz) | 220 50/60 |

| Motor Torque(g/cm) | 2000 |

1.What is the glass texture?

The full set of glass parts is produced by GG-17 high borosilicate glass, owns excellent chemical and physical properties.

2.What kind of regular maintenance is required for the glass reactor?

The glass reactor vessel is maintained once a week, scrubbed and coated with a small amount of grease. Check the degree of wear (corrosion) of the seal and replace the worn (corroded) seals in time to ensure the vacuum of the equipment.

3.How do you package the glass reactor equipment for shipment?

We package our products in special cartons and you can order fumigation boxes if you have special requirements.

4.What's the max temperature?

Usually, the high borosilicate glass can withstand over 300-degree centigrade and the PTFE stirring bar can withstand about 200-degree centigrade.