-

WhatsApp

-

Email

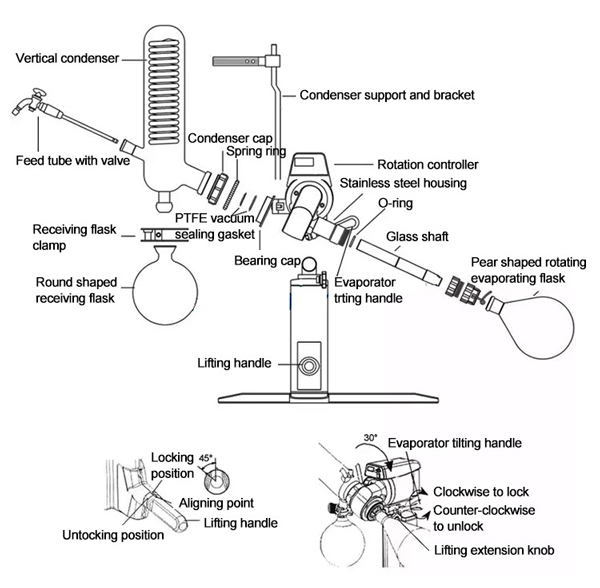

The N-1100d rotary evaporator is a kind of 2l small rotary evaporator uses an AC induction motor and a PID temperature control device for long-term operation and precise temperature control. Heating, under this condition: the material forms a large area of uniform film on the inner wall of the evaporating flask, which can improve the evaporation efficiency under vacuum conditions (need to connect a vacuum device), and the solvent vapor is cooled to liquid when it passes through the glass condensation coil (need to connect a cooling device) , recovered in the collection bottle. The 2l rotary evaporator needs to be equipped with a vacuum device (circulating water type, rotary vane type, diaphragm type, etc. vacuum pump), and the cooling circulation device constitutes a system device.

Basic configuration of 2l rotary evaporator:

1. The parts in contact with the material are all made of high borosilicate glass (expansion coefficient 3.3) and polytetrafluoroethylene material, which has stable performance and is not easy to chemically react with the material.

2. The main bracket is made of aluminum alloy, and the inner pot is made of 304 stainless steel.

3. The sealing system adopts Teflon + fluorinated rubber double seal.

4. The piston-type feeding valve is socketed with a PTFE extension tube, which can continuously feed to the evaporating flask under vacuum.

5. Integrated condenser, vertical double-layer serpentine coil.

6. Warp button (ON-OFF), rotation, heating power switch control.

7. Electronic stepless speed regulation, fine-tuning through the knob, digital display of the speed.

8. The temperature of the constant temperature bath is digitally displayed, and the bottom of the pot is a PT100 sensor + a stainless steel probe.

9. The main engine is manually lifted, sliding lift + manual lift two-speed lift.

10. Rotation, heating double fuse safety protection.

2l rotary evaporator product features:

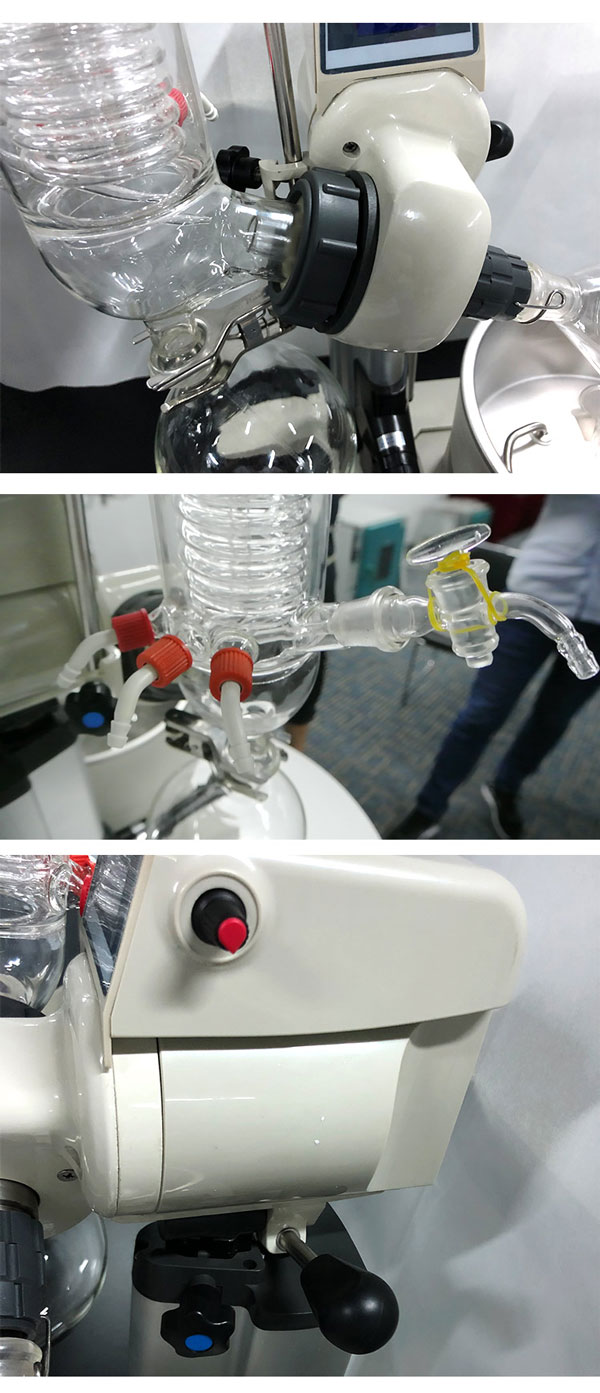

1. V type adopts vertical cooler, which occupies a small area. The four-way bottle structure is adopted, and the concentrated liquid is directly returned to the collection bottle from the condenser tube, and will not flow back into the sample bottle along the suction tube. It is suitable for the concentrated use of analytical samples without polluting samples.

2. The height of the vertical condensing pipe has been reduced, but due to the use of fine technology, the number of turns of the coil pipe has been increased, and the cooling area has been increased. Because the position of the suction (decompression) joint is changed to the lower part, it is safer to connect with the vacuum tube.

3. The lifting operation of the main body is very convenient, and the lifting handle can move up and down smoothly and lock it reliably. There is an auxiliary extension on the upper part of the main body to adjust the position of the buffer bottle or small sample bottle, and it can extend and slide up and down 30cm from the opening.

4. It can be used in connection with the solvent recovery device DPE-1300·1400. The DPE type recovery bottle can collect organic solvents, and the waste liquid container can be recovered in a closed flow path through the operation of the live lock to avoid exposure of the solvent to the air.

5. The VF type of explosion-proof coated glass used in the condensation pipe, recovery bottle and four-way bottle has the same transparency and excellent physical properties as the standard type. This design solves the problem of glass scattering and hurting people in case of damage.

6. When used in combination with the vacuum controller NVC type connection, the recovery efficiency of the rotary evaporator can be greatly improved.

7. There is also the N-1100VD type suitable for the concentration of dioxin analysis samples. The part where the sample bottle and the rotating shaft are combined is transparent, not the ground interface. In order to prevent contamination when the vacuum is released, an O.2µm air filter membrane is equipped.

2l rotary evaporator advantages:

1. It adopts a simple vertical cooler, an excellent product with high cost performance, and occupies a small area.

2. The height of the vertical condenser pipe has been reduced, but due to the use of fine technology to increase the number of coils of the coil pipe, the cooling area has been increased by 30%, up to 0.146m2.

3. The lifting operation of the main body is very convenient, and the lifting handle can move up and down smoothly and lock it reliably. There is an auxiliary extension on the upper part of the body to adjust the position of the buffer bottle or small sample bottle, and it can extend and slide 15cm up and down from the opening.

4. Equipped with a backflow prevention joint to prevent backflow.

5. When used in combination with the vacuum controller NVC type connection, the recovery efficiency of the rotary evaporator can be greatly improved.

6. Optional full Teflon gasket with excellent chemical resistance for low boiling point organic solvent recovery, etc.

| Product Name | Rotary Evaporator | |

| Model | N-1100-D | |

| Performance | Rotary Speed(rpm) | 10~180 |

| Evaporation rate(ml/min) | 20 | |

| Max.Vacuum Degree(Pa) | 399.9(<3mmHg) | |

| Function | Rotary Speed Setting |

Knob type stepless speed control. LCD display |

| Security | Overload protection | |

| Lifting | Manual weight balancing | |

| Structure | Electric Motor | Output power 25W |

| Condenser | Double Spiral Coil | |

| Rotary Bottle(L) | 1~2 | |

| Receiving Bottle(L) | 1 | |

| Glass Rotating Shaft(mm) | φ15*190 | |

| Seal Ring |

Teflon, fluorinated rubber double seal |

|

| Specification | Interface Caliber(mm) | Outer diameter φ10 |

| Machine base(mm) |

T-shaped frame 460*320 |

|

| Lifting Height(mm) | 100+150 slide and manual | |

| Operating Temp.(℃) | 5~35 | |

| Current and Power(A/W) | 0.16/35 | |

| Weight(kg) | 9.5 | |

1. Can the N-1100-D rotary evaporator use a rotary vane vacuum pump?

We do not recommend the use of a rotary vane vacuum pump because the rotary vane vacuum pump generates water vapor when it is evacuated. The N-1100-D rotary evaporator does not have a portion that condenses water vapor. Once the water vapor enters the rotary vane vacuum pump, the vacuum pump will overheat and cause damage to the vacuum pump.

2. What are the requirements for the selection of the cryogenic cooling equipment of the N-1100-D rotary evaporator?

For the cryogenic cooling equipment of the rotary evaporator, it is recommended to select the DLSB-5/10 model low temperature coolant circulating pump produced by our company. The cooling capacity of this model is 5L and the minimum temperature is -15 °C. Our N-1100-D rotary

evaporator has a rotating bottle capacity of 1~2L, so the DLSB-5/10 cryogenic coolant circulation pump is fully suitable for the N-1100-D rotary evaporator.

evaporator has a rotating bottle capacity of 1~2L, so the DLSB-5/10 cryogenic coolant circulation pump is fully suitable for the N-1100-D rotary evaporator.

3. What is the maximum temperature?

Temperature range: RT - 180 °C oil bath.

Temperature range: RT - 99 °C water bath.