-

WhatsApp

-

Email

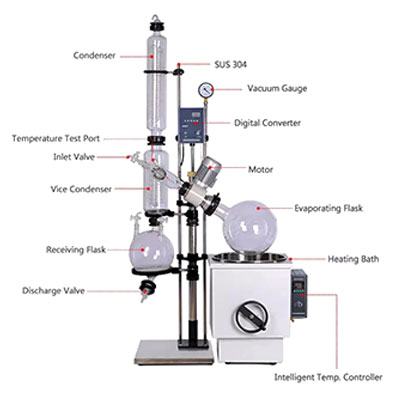

RE-1002 is one of our 10L rotary evaporator, the principle is: under the condition of negative pressure, the rotating bottle rotates at a constant speed in a water bath heated at a constant temperature, and the material forms a large-area film on the wall of the bottle to improve the evaporation efficiency. The lysozyme vapor was cooled by a glass condenser and recovered in a collection bottle. This product is especially suitable for the concentration and purification of biopharmaceuticals that are easy to decompose at high temperature. According to the company's more than 20 years of practical experience, a series of 2L, 3L, 5L, 10L, 20L, 50L and other rotary evaporators have been developed and produced. At present, they have been invested by various universities, scientific research laboratories, factories and other units. use.

10L rotary evaporator product advantages:

1. The main bracket is made of stainless steel + aluminum alloy, with reasonable structure and exquisite materials.

2. The vacuum pressure gauge shows the real-time vacuum degree, which can reach -0.098Mpa.

3. The glass parts are made of high temperature and corrosion resistant high borosilicate glass.

4. Continuous feeding is convenient for customers to use

5. Vertical double-layer serpentine coil condenser to ensure high recovery rate, with additional material pipe.

6. The temperature control of the heating bath is easier to operate and more precise.

7. Advanced frequency conversion digital display speed regulation ensures electrical performance, digital display of speed, knob setting, and easy operation.

8. Fuses can be used for safety protection.

9. Equipped with high-efficiency double-tube condenser.

10L Rotary Evaporator Features:

1. Heating device: The inner tank of the water bath is made of 304 stainless steel plate for one-time stamping; intelligent temperature control, PT100 sensor digital display, can ensure that the temperature control accuracy of the user can reach ±2°C when using.

2. Rotary evaporation device: the glass material is high borosilicate glass (GG-17) high temperature and corrosion resistant; the rotary sealing component is made of PTFE (polytetrafluoroethylene) and fluorine rubber, which can maintain a high degree of vacuum during vacuuming.

3. Cooling recovery device: adopt high borosilicate glass (GG-17) double return ball milling mouth condenser tube. The large-diameter triple-reflux spiral condensation structure increases the condensation area and saves time and money.

4. The structure is reasonable. The mechanical structure adopts a large number of stainless steel and aluminum alloy parts, and the glass parts are all made of high temperature resistant high boron glass. The key parts of electrical appliances are imported, and the fluorine rubber seals have all adopted the new national standards, which is convenient for users to purchase and replace.

10L rotary evaporator advantages:

1. Gas-liquid separator, no reflux.

2. Double condenser, collection rate over 95%.

3. The rotating flask is easy to install and setup.

4. Continuous feed are available. (Inlet Valve).

5. Water bath, intelligent PID temp. controller, can be lifted up and down.

6. Reasonable structure, exquisite material.

7. Built-in transmission system, frequency conversion speed regulation, stable and reliable speed.

8. Explosion-proof system is optional.

9.220 V 50/60HZ can be customized.

10L rotary evaporator installation:

1. Lay the rack flat.

2. Put the machine head into the machine head installation hole with a diameter of 30mm, tilt the axis of the machine head to the right by about 250°, lock the right hand wheel, screw the M6 headless screw to the bottom and back out one turn.

3. Fix the four-way artist with a large nut on the left side of the machine head.

4. Insert the condenser on the four-way bottle, adjust the movable joints to make the condenser vertical.

5. Install the hoop, insert the hoop support rod into the slider above the pole, wrap the steel belt around the condenser, and tighten the relevant screws.

6. Install the collection bottle at the lower end of the four-way bottle, and clamp the bottle chuck. The lower installation tray is supported stably.

7. Install the rotating bottle on the right end of the rotating shaft, and clamp the bottle chuck.

8. Connect the long feeding pipe with the feeding pipe (if it is too tight, you can use boiling water to heat it). Insert into the hole of the rotating shaft.

9. Fix the electric control box according to the figure, plug in the seven-pin plug of the motor, and then turn on the power for a test run.

10. Connect the two ports on the vacuum gauge, one end to the condenser, and the other end to the vacuum pump.

11. Connect the cooling water pipe and put the water bath away.

| Model | RE-1002 |

| Evaporating Flask (L) | 10 |

| Receiving Flask(L) | 5 |

| Rotating Motor(W) | 180 |

| Rotating(R/min) | 0-120 |

| Evaporation Speed(L/H2O) | >3L/h |

| Condenser Cooling Surface (sq.m.) | 0.57 |

| Vacuum Degree | 0.098Mpa |

| Sealing Mode | PTFE Sealing System |

| Max Vacuum Degree | <133pa |

| Water Bath Configuration | Water Bath Lifting or Electric Hois |

| Water(Oil) Bath Power(kw) | 3 |

| Temperature Control Range | 0-99(250)℃ |

| Temp Fluctuation/Resolution | ±1/1℃ |

| Condenser | Vertical Double Condenser |

| Voltage (V/Hz) | 220V 50/60 |

| Note | Customized configuration is available. |

1. How long can the rotary evaporator work continuously?

The rotary evaporator can work all the time, but it needs to be shut down for maintenance and maintenance after running for a period of time, which can increase the service life of the equipment.

2. Does the circulating water vacuum pump have 110V/60Hz power?

Of course, the vertical circulating water vacuum pump has vacuum pump equipment of different powers such as 220V/50Hz, 220V/50Hz, 110V/60Hz. The SHZ series of circulating water vacuum pumps are suitable for rotary evaporators of 10L, 20L and 50L.

3. How to package glass equipment?

We package these glass equipment in a good non-fumigation standard plywood box, which can reduce the shock and better protect the glass part of the equipment.