-

WhatsApp

-

Email

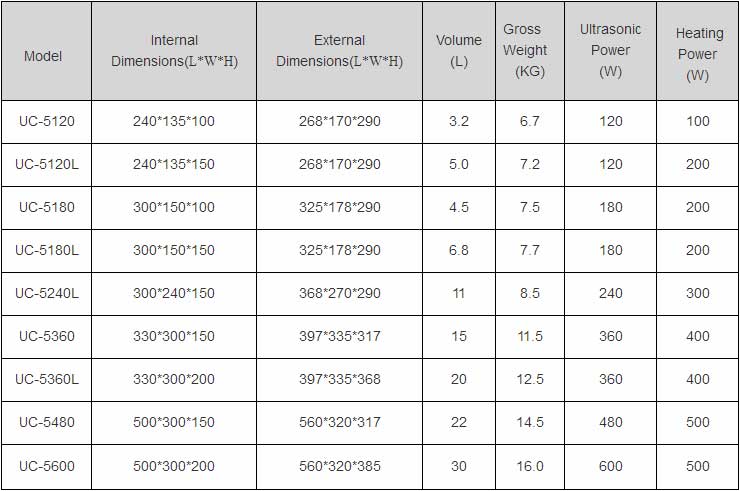

The surface of the UC series stainless steel ultrasonic washing machine is electrolytically polished, which has a good anticorrosive effect. The cleaning time is 1-99 minutes and the temperature is 1-80 ° C.

With the main research and development of industrial-grade high Q value sensors, the ultrasonic conversion efficiency is high, long life.

Features

- Independently research and develop the MCU-weep ultrasonic generator drive circuit, the ultrasonic effect is even and strong.

- Independent research and development of industrial-grade high Q value transducer, high ultrasonic conversion efficiency, and long service life.

- One-button degassing function, quick removal of water in the air, the better ultrasonic cleaning effect

- Power adjustment function can be adjusted according to different requirements of cleaning products to achieve the best cleaning effect

- Imported high-strength glue, no nail bonding process, the longer service life of the tank.

- Digital timing, cleaning time 1-99min and digital heating control, temperature 1-80 °C arbitrary setting.

- The inner tank is made of imported SUS304 and 1.0mm stainless steel.

- The washing basket is made of high quality 304 stainless steel mesh and the surface is electrolytically polished.

- The shell is made of high-quality stainless steel for better anti-corrosion effect.

Detail

As a popular cleaning equipment, ultrasonic cleaner is suitable for the following industries:

Ultrasonic cleaners are widely used in surface spray treatment, machinery, electronics, medical, semiconductor, watch and jewelry, optics, textile printing and other industries.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. What should I pay attention to when using the ultrasonic cleaner?

- Ultrasonic cleaner power and electric heaters must have a good grounding.- It is forbidden to start the ultrasonic cleaning machine without the cleaning liquid. That is, the cleaning cylinder does not add a certain amount of cleaning liquid, and the ultrasonic switch cannot be turned off.

- Do not use heating equipment with heating equipment to turn on the heating switch when there is no liquid.

- Do not use heavy objects (iron blocks) to clean the bottom of the cylinder to avoid damage to the inverter chip.

- The ultrasonic generator power supply should be separately configured with a 220V/50 power supply and 2000W or higher voltage regulator.

- Clean the bottom of the cylinder regularly without excessive impurities or dirt.

- Each time the new fluid is replaced, the parts must be ultrasonically activated before they can be cleaned.

2. The following principles should be followed when purchasing an ultrasonic cleaner.

- Power selection- Frequency selection

- Use of cleaning the cage

- Selection of cleaning fluid temperature

- About the amount of cleaning fluid and the location of the cleaning parts