-

WhatsApp

-

Email

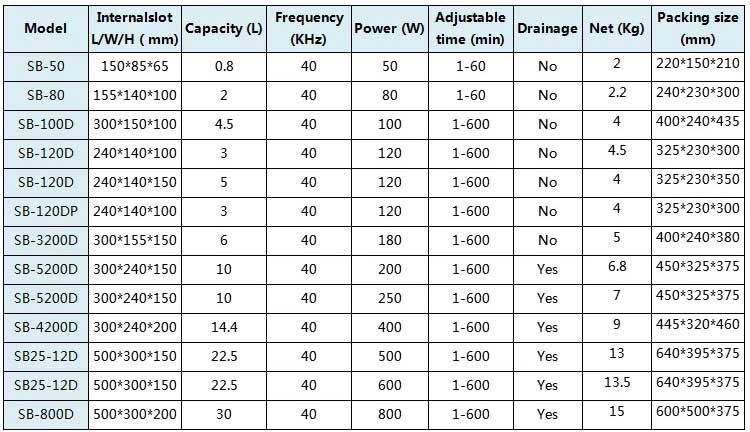

The SB series ultrasonic cleaner has a capacity of 1L ~ 30L, which can be used for cleaning, watches, dentures, jewelry, small precision machinery and equipment, electronic equipment, medical equipment and so on.

And can customize the ultrasonic cleaning machine of any frequency.

Features

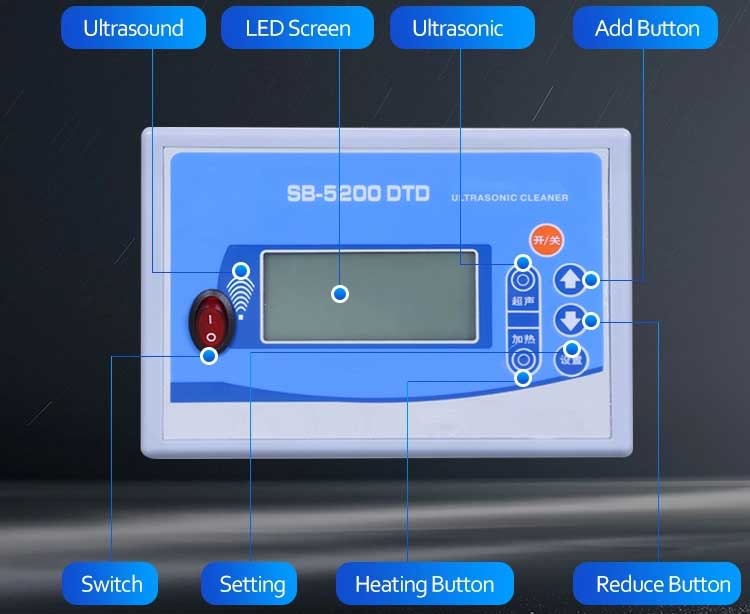

- The operation of the instrument using the microcontroller software.

- 1-999MIN total working time setting.

- Equipped with a dedicated stainless steel basket and sound cover.

- Real-time display of the actual temperature in the cleaning tank.

- Working parameters outage memory function.

Detail

As a popular cleaning equipment, ultrasonic cleaner is suitable for the following industries:

Ultrasonic cleaners are widely used in surface spray treatment, machinery, electronics, medical, semiconductor, watch and jewelry, optics, textile printing and other industries.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. Technical characteristics of ultrasonic cleaning machine cleaning.

The cleaning speed is fast, the production efficiency is improved, and the cleaning liquid is not required to be touched by human hands, which is safe and reliable. Deep holes, slits and hidden parts of the workpiece can also be cleaned. No damage to the surface of the workpiece, saving solvent, heat, work site and labor.

The ultrasonic cleaning method is more effective than the conventional cleaning method, especially the surface of the workpiece is more complicated, the surface is uneven, and the mechanical parts have blind holes.Some products that are particularly small and have high requirements for cleanliness, such as clocks and precision mechanical parts, electronic components, circuit board components, etc., can achieve very good results using ultrasonic cleaning.

2. How does the ultrasonic cleaner work?

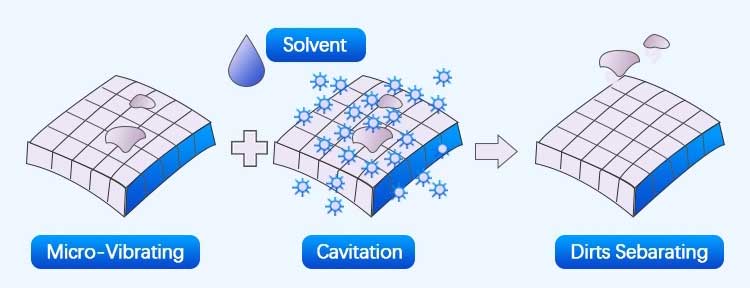

Ultrasonic cleaning is the use of ultrasonic cavitation in the liquid, acceleration and direct flow effects on the direct and indirect effects of liquid and dirt, so that the dirt layer is dispersed, emulsified, separated to achieve cleaning purposes.

3. What are the advantages of the ultrasonic cleaner?

The ultrasonic cleaning effect is good and the operation is simple. According to the transmission of sound waves, the initial propagation of the sinusoidal curve produces a large number of small bubbles. One reason is that tensile stress is locally generated inside the liquid to form a negative pressure. The decrease in pressure causes the gas of the original small amount of liquid to be supersaturated, and escapes from the liquid to become a small bubble; another reason is that the strong tensile stress "rips" the liquid. Become a hollow, called cavitation.