-

WhatsApp

-

Email

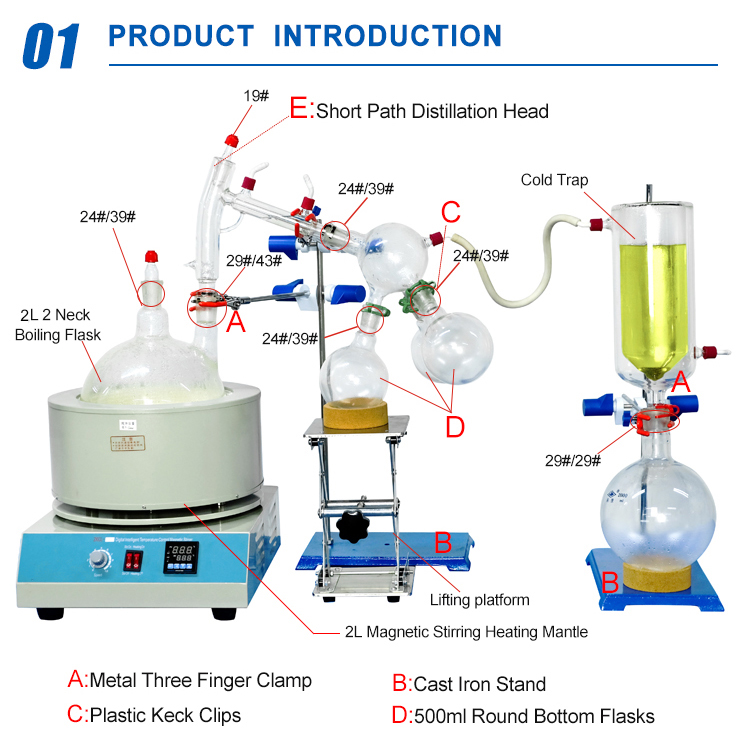

Introduction to short path distillation:

Short path distillation is a distillation technique that utilizes reduced pressure to allow components with lower boiling points to travel a short distance and condense onto a condenser column for distillation purposes. Because the vaporized components travel a short distance, usually only a few centimeters, it is called short path distillation apparatus. A short path fractionator kit is a distillation technique that involves the distillate traveling a short distance, usually just a few centimeters, usually under reduced pressure. A typical example is distillation, where distillate flows from one glass bulb to another without the need for a condenser to separate the two chambers. This technique is typically used for compounds that are unstable at high temperatures or to purify small amounts of compounds.

Distillation equipment requires iron racks, alcohol lamps, stills, thermometers, condensers, long tubes, asbestos nets, conical flasks with branch ports, rubber stoppers, trumpet tubes, beakers and other instruments. Distillation refers to the mass transfer process that uses the difference in the volatility of each component in the liquid mixture to separate the components. Compared with methods such as extraction and filtration crystallization, the advantage is that no solvent other than the system components is required, and no new solvents are introduced. impurities. Distillation can be divided into simple distillation, equilibrium distillation, rectification and special distillation, batch distillation and continuous distillation according to the operation mode. The main distillation instruments are: distillation bottle (with branch pipe), thermometer, condenser tube, horn tube, alcohol lamp, asbestos net, iron frame, rubber stopper, etc.

How Short Path Distillation Works:

The short-path evaporator generally consists of a vertical jacketed cylindrical distillation unit, an inner condenser and a film-forming system. The operation process of short path distillation apparatus can be briefly summarized as follows: the material to be distilled is continuously injected into a high-speed rotating disc, and under the action of centrifugal force, the material is distributed on the inner surface of the distillation unit. The distillation unit is heated uniformly and continuously using a heating medium (electricity, steam or thermal oil). The injected raw material is evenly distributed on the inner surface of the cylinder by the film forming system and moves downward under the action of gravity. Under a certain temperature and vacuum degree, some components will evaporate on the heated surface, and the composition of the components in the liquid phase will change at the same time. The substances that are evaporated into gas are converted into liquid by the built-in condenser and collected. The heavy components that cannot be evaporated flow out along the inner wall of the evaporator.

Advantages of short-path distillation units:

short path distillation working principle has two absolute advantages: on the one hand, the absolute pressure in the distillation unit is reduced to 0.01mbar, which can greatly reduce the boiling point of the distilled substance; at the same time, the specially designed distillation unit structure is used to shorten the heating time of the substance to 0.01 mbar. 1 and within n. The reduction of distillation temperature and the shortening of heating time make short path distillation working principle, for those high-boiling heat-sensitive substances that need to be separated by distillation, to avoid thermal decomposition to the greatest extent to maintain the original chemical and biological active structure of the substance.

Compared with ordinary rectification, short-path rectification has the following characteristics: as long as there is enough temperature difference between the hot and cold sides, it can be carried out at any temperature, and it can be a non-boiling distillation process; it is an irreversible process; separation capacity and vapor pressure of components It is related to the ratio of relative molecular mass, the greater the difference in relative molecular mass, the purer the distillate. Due to the above characteristics, short path distillation working principle is particularly suitable for the separation of high boiling point, heat sensitivity and easy-oxidation systems, and is widely used in food, cosmetics, pharmaceuticals, aerospace, plastics, petrochemicals, wax, paper and other fields. However, for the short-path rectification mechanism, the description of mass transfer and heat transfer process, the establishment and design of mathematical model

The influence and optimization of the equipment structure and operating conditions on the degree of separation need to be further studied.

The advantage is that the heating temperature (under reduced pressure) can be well below the boiling point of the liquid at standard pressure, and the distillate only has to travel a short distance before condensing. The short path ensures that there is virtually no compound loss on the side of the device.

Application of Short Path Distillation Unit:

In industrial production, a large number of heat-sensitive materials can be processed by short path distillation equipment for sale.

(1) The content of volatile components is very small, and the separation is recovered from the product as a residual liquid. Separation of pesticides, cosmetics, fragrances and other raw materials from milk fat, deodorization, separation of monomers in silicone oil.

(2) Separation of substances in very thin mixed liquids High concentrations of vitamins (A or E) need to be separated from the oil at a temperature of 200°C. Using a pre-degassed secondary unit, the recovery rate was greater than 80% at a pressure of 0. IPa and a production capacity of SOkg/mZh.

(3) High-yield raw material refinement purification of two-carbon grease for modern lubricants. Recovery of the catalyst from the reaction would be extremely difficult for conventional distillation. However, using a secondary short-path distillation unit with a production capacity of Zookg/m”h, at 20°C and 1Pa, a recovery rate of 90% can be obtained. In addition, it can also be used for: the refining of ethylene glycol; the refining of mushroom thin fat.

(4) Separation of Materials Containing Different Boiling Points Monoglycerides used as emulsifiers in the food industry can be produced by partial hydrolysis of triglycerides. The reaction mixture was composed of 50% monoester and some other components, almost no diester. Since monoesters are heat-sensitive, they cannot be concentrated by fractional distillation. If a two-stage short path distillation apparatus device is used, a single lipid with a concentration of more than 90% can be obtained, and the recovery rate can reach 80%. In addition, it can also be used for: separation of various chain fatty acids; distillation of epoxy resins; distillation of isocyanates.

(5) Recovery of reusable components in silicone oil will lead to an increase in vapor pressure due to impurities. Therefore, after a certain period of time, it must be replaced by the diffusion pump to drive the liquid.