-

WhatsApp

-

Email

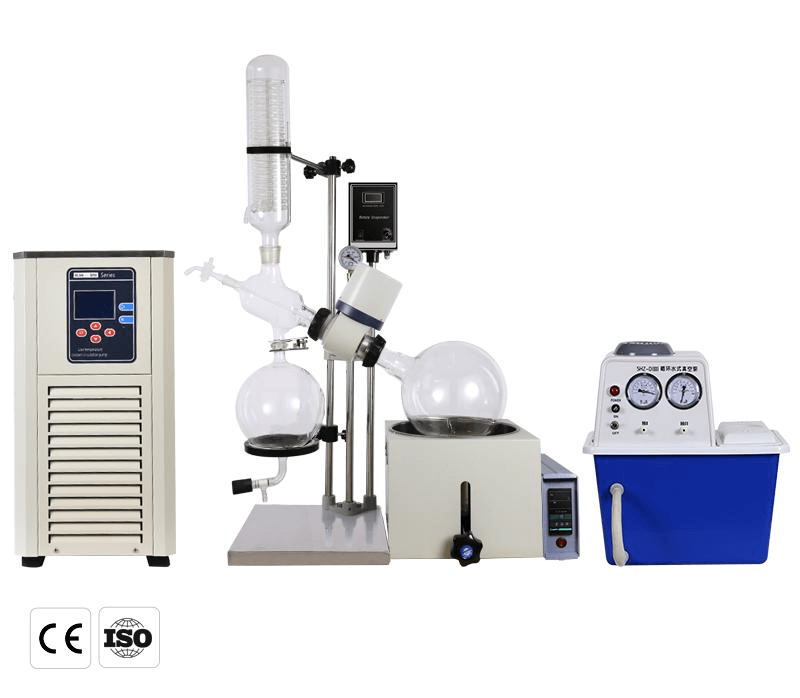

In the realm of laboratory equipment, the 20 liter rotovap with chiller and vacuum pump stands as a cornerstone of modern scientific research and industrial processes. This intricate system, developed and supplied by leading companies like ZZKD Machinery and Instrument Equipment Co., Ltd., has revolutionized processes such as extraction, distillation, and concentration. With over 13 years of experience in producing and exporting such equipment, ZZKD has emerged as a trusted name in the field, catering to clients globally. In this article, we delve into the workings of the rotary evaporator with chiller and vacuum pump, exploring its components, applications, benefits, and the role of industry leaders like ZZKD.

Understanding the Rotary Evaporator System

Component Breakdown

At its core, the rotary evaporator with chiller and vacuum pump is a meticulously engineered system designed to facilitate the separation of solvents from samples. The system comprises three primary components: the rotary evaporator itself, the chiller, and the vacuum pump. The rotary evaporator features a rotating flask that holds the sample, a heated water bath, a condenser, and a collection flask. The chiller, a cooling apparatus, maintains the low temperatures required for efficient solvent condensation. The vacuum pump, as the name suggests, creates a vacuum environment, reducing the boiling point of the solvent and enabling quicker evaporation.

Working Principle

The rotary evaporator's operation hinges on the principle of reduced pressure and controlled temperature. As the sample flask rotates in the water bath, the solvent begins to evaporate. Simultaneously, the vacuum pump lowers the pressure in the system, further aiding evaporation by minimizing the boiling point of the solvent. The vapor then rises and enters the condenser, where it is cooled by the chiller. The condensed solvent drips into the collection flask, leaving behind the concentrated sample. This gentle yet effective process prevents thermal degradation of sensitive compounds, making the rotary evaporator with chiller and vacuum pump indispensable in applications like essential oil extraction, solvent recovery, and more.

Applications of Rotary Evaporators

Chemical and Pharmaceutical Industries

In the chemical and pharmaceutical sectors, rotary evaporators with chillers and vacuum pumps have become integral tools. These industries often deal with compounds that require careful handling to avoid degradation. The system's controlled evaporation process ensures that valuable compounds are separated without subjecting them to high temperatures, preserving their integrity. Pharmaceutical laboratories utilize rotary evaporators to extract active ingredients from natural sources, synthesize compounds, and purify substances.

Food and Beverage Technology

The applications of rotary evaporators extend to the food and beverage sector, where the extraction of flavors and fragrances plays a crucial role. Manufacturers can isolate desired flavors from natural sources like herbs, fruits, and spices, creating high-quality extracts that enhance the taste and aroma of products. By utilizing the rotary evaporator system, companies can produce extracts free from harsh chemicals, aligning with the growing consumer demand for natural and clean-label products.

Environmental Analysis

Rotary evaporators find utility in environmental analysis, particularly in the detection of volatile organic compounds (VOCs) in air, water, and soil samples. The system aids in concentrating these compounds, making them easier to detect and analyze. This application proves vital in environmental monitoring, helping researchers and regulatory bodies assess pollution levels, track sources of contamination, and devise mitigation strategies.

Advantages of Using Rotary Evaporators with Chillers and Vacuum Pumps

Enhanced Efficiency

The integration of a chiller and vacuum pump with the rotary evaporator significantly enhances efficiency. The chiller ensures optimal cooling, preventing solvent loss and facilitating quicker condensation. Meanwhile, the vacuum pump accelerates evaporation by maintaining a reduced pressure environment. This combination drastically reduces processing time, making the system ideal for time-sensitive applications.

Preservation of Sensitive Compounds

The gentle evaporation process of the rotary evaporator prevents the degradation of sensitive compounds. Unlike traditional methods that involve high temperatures, this system allows compounds like essential oils and delicate flavors to be extracted without compromising their quality. The controlled environment and low boiling points ensure that volatile compounds remain intact.

Cost Savings

The use of a rotary evaporator with chiller and vacuum pump can lead to substantial cost savings in the long run. The efficiency of the system translates to reduced energy consumption, shorter processing times, and higher yields. Additionally, the preservation of valuable compounds eliminates the need for repeated extractions, optimizing resource utilization.

Conclusion

In the landscape of modern laboratory equipment, the rotary evaporator with chiller and vacuum pump emerges as a cornerstone of innovation. Its ability to delicately extract, distill, and concentrate compounds while preserving their integrity makes it a versatile asset across industries. ZZKD Machinery and Instrument Equipment Co., Ltd. has exemplified excellence in providing these systems, harnessing over a decade of experience to cater to a global clientele. As technology advances and research evolves, the rotary evaporator's role will continue to expand, contributing to scientific breakthroughs, industrial progress, and a sustainable future.