-

WhatsApp

-

Email

Freeze dryer is also called freeze dryer. A freeze dryer for candy is a freeze-drying device that first freezes water-containing substances into a solid-state, and then sublimates the water in it from a solid-state to a gaseous state to remove moisture and preserve the substance.

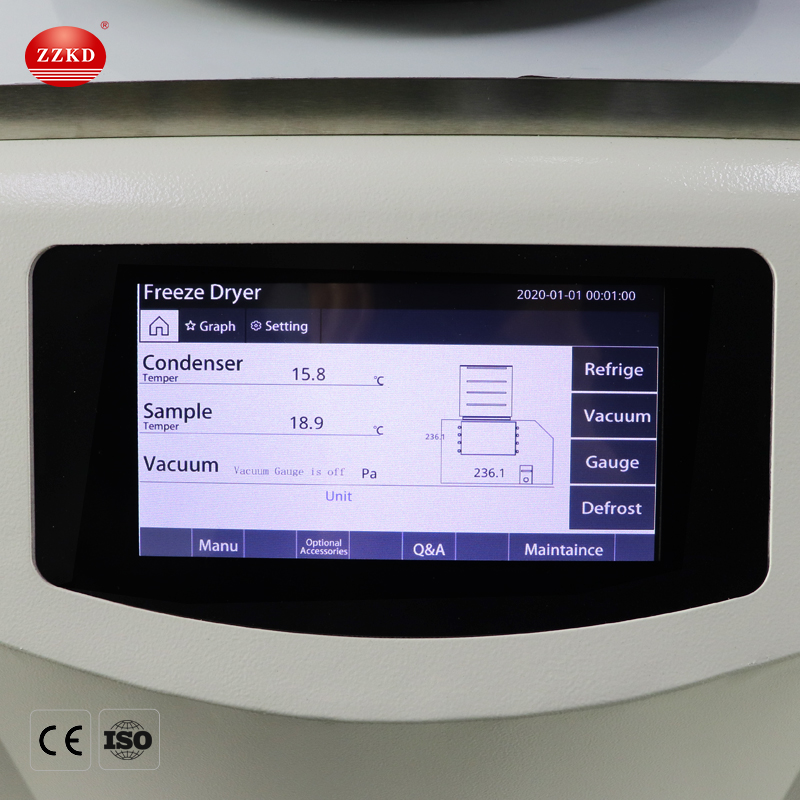

Basic structure of freeze dryer

The freeze dryer is composed of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. The main components are drying box, condenser, refrigeration unit, vacuum pump, heating/cooling device, etc.

The refrigeration system is the most important part of the freeze drying flowers equipment and is called the "heart of the freeze dryer". Its refrigeration system is mainly composed of the following components: compressor, refrigerant, oil separator, water condenser, filter drier, intercooler, sight glass, solenoid valve, hand valve (top cover valve), expansion valve, evaporation (plate exchanger, rear box condenser coil), vapor-liquid separator, return air filter, pressure gauge, pressure control relay, CPCE (energy regulator), safety valve, refrigeration pipeline, etc.

The drying box is a vacuum-tight low-pressure container. The materials are all made of stainless steel, which can withstand positive and negative pressure and meet the requirements of steam sterilization. The sealing adopts high-temperature and low-temperature resistant silicone rubber, and the thermal insulation layer adopts closed-cell elastic thermal insulation material.

Box: It is a rectangular box with high space utilization, with a drainage outlet at the bottom and an observation window on the side. Shower inlet connector.

Shelf: The energy required to cool and open the food is conducted to the shelf and then to the food through the heat exchange medium. The shelf adopts special hollow plywood, which has high strength and good sealing performance. The shelf assembly is installed in the freeze-drying box through a bracket, and a board layer should be set as a heat radiation compensation plate on the uppermost layer to ensure that the food space in the box is the same temperature environment. Set rails to keep food pans or food from falling off the shelves.

Box door: using cylinder automatic locking device. Make sure: The vacuum degree is required during the internal pressure process of the box. When the vacuum pump is working, open the butterfly room of the thousands of boxes. The air and water vapor in the vacuum drying chamber pass through the water catcher to capture the moisture and then enter the vacuum pump and are discharged from the system through the exhaust port of the vacuum pump. To prevent the smoke in the exhaust gas from polluting the indoor environment. To prevent water vapor from entering the pump, the system is equipped with a gas ballast valve, which is opened during the drying process.

Media heat exchange circulation system of freeze dryer for candy

The energy required for the cooling and heating of the food is driven by the circulating pump and transmitted to the shelf through the heat exchange medium, and then to the food. The cold source for food cooling is provided by the refrigeration system, the heat source for food heating is provided by the heating tank, and the switching between cooling and heating is accomplished by controlling the electromagnetic valve switch of the cold source and the heat source. When the temperature rises, the steam enters the heating medium of the heating tank, and the mixing ratio of the heating medium from the heating tank and the heating medium returned from the shelf is adjusted by a pneumatic three-way regulating valve, and the opening and closing of the cooling water and electricity valve of the plate heat exchanger is controlled to control the shelf. temperature. The system includes a heat medium heating tank plate heat exchanger, pneumatic control valve, cooling water solenoid valve, circulating pump, pipeline, solenoid valve, temperature sensor, etc.

Food freeze dryer for candy

Freeze-drying technology is a method of food dehydration at present. The technology is to freeze the water-containing material at low temperature, and then directly sublime the water in it in a vacuum state. The purpose, like the vegetable bag in the instant noodles that we usually eat, adopts this vacuum freeze-drying technology to achieve dehydration treatment, so how does the vacuum freeze-drying machine achieve the dehydration function?

1. How does the vacuum freeze drying flowers equipment realize the working principle of the dehydration function. The working principle of the vacuum freeze dryer is that the compressed air first enters the pre-cooler for preliminary cooling, and then flows into the regenerator to exchange heat with the returned product gas to further cool the compressed air and discharge the condensed water out of the machine. . After that, the compressed air flows into the evaporator and exchanges heat with the refrigerant to further cool the compressed air to reach the required temperature.

2. How does the vacuum freeze dryer realize the processing process of the dehydration function

After the vacuum food freeze dryer for sale is turned on, the products that need to be freeze-dried are put into the freeze-drying chamber for freezing treatment. This is the process of freezing the products. This has two advantages. On the one hand, the vacuum system of the vacuum freeze drying flowers equipment realizes the function of vacuuming the product, which can take away part of the water; surface is frozen. When the freezing requirement is met, the product is heated and dried by the heating system, and the moisture contained in the product is brought to the freezer collection box by vacuuming to freeze, so as to meet the product freeze-drying requirement from the surface.

The physical, chemical and biological states of the product after vacuum freeze-drying are basically unchanged. The product after freeze-drying is porous, and its volume is basically the same as before drying. Therefore, after adding water, due to the large contact area, it can be quickly restored and has a long shelf life in a sealed container. It is also widely used in various industries. In the selection of vacuum food freeze dryer for sale, it is necessary to carry out actual investigation and reflect the processing effect of its product through on-site test machine. Only in this way can we choose a vacuum freeze dryer suitable for the product.