-

WhatsApp

-

Email

Cannabis has a long history as a medicinal plant, possibly dating back two thousand years. THC, the main psychoactive compound in cannabis, is responsible for stimulating specific receptors in the brain, causing effects and changes such as reducing pain and inflammation, increasing appetite, nausea, and insomnia. The extract can be given as medicine to patients suffering from various diseases. For example, medical marijuana in the U.S. is used to treat pain, MS-related spasticity, nausea, post-traumatic stress disorder, cancer, epilepsy, cachexia, glaucoma, HIV/AIDS, and degenerative neuropathy

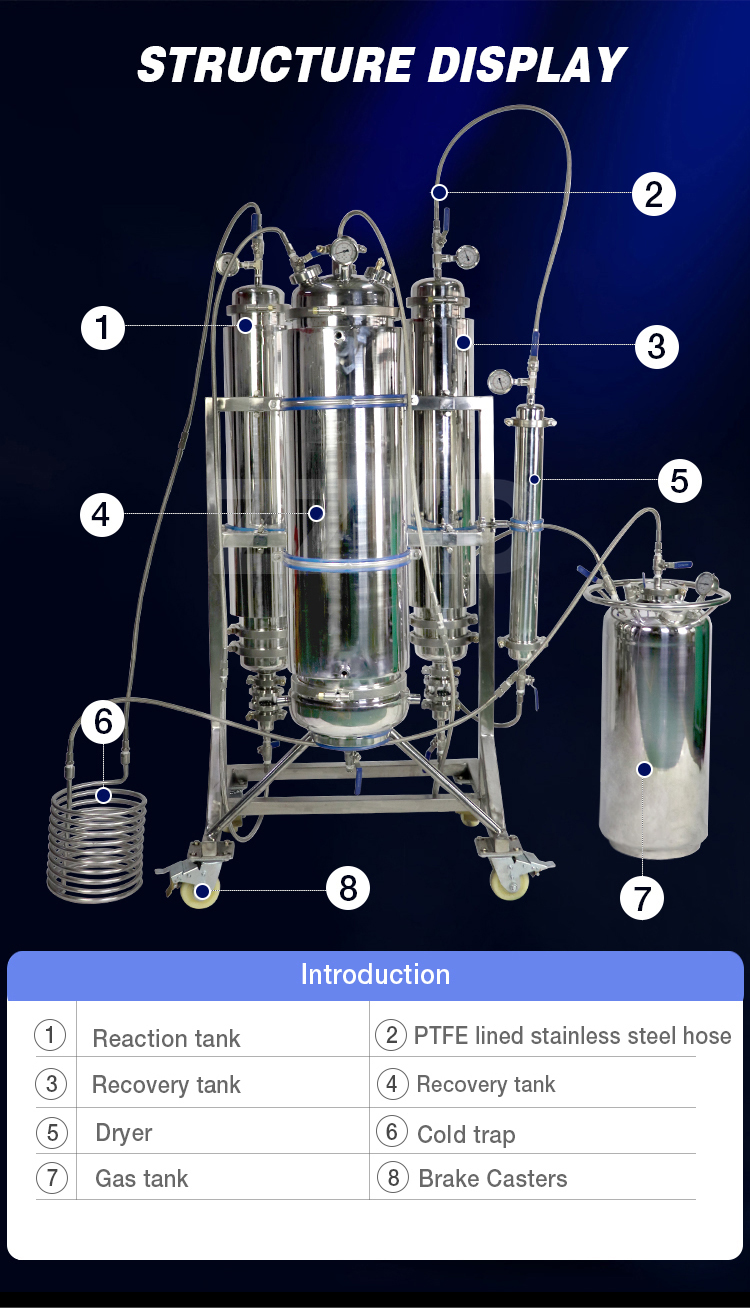

Introduction of closed loop extractor:

Bho extraction closed loop use subcritical fluids as extractants. In a closed, oxygen-free, low-pressure container, according to the similar principle of the compatibility of organic substances, the extract and the extractant undergo molecular diffusion during the soaking process, so that the fat-soluble components in the solid matter are transferred to the liquid extractant, and then evaporated by vacuum. The process separates the extractant from the target product, and finally obtains a new type of target product extraction and separation technology. Our 1lb passive closed loop extraction kit are mainly composed of Extraction Column Valve, Low-Pressure Recovery Manifold, High-Pressure Recovery Manifold, Purge Port, Recovery Cylinder, Vacuum Pump, Recovery Pump, Recovery Pump, Dehydration Column or Filter Drier, Extraction Column, Extractor Collection Chamber.

In addition to active ingredients such as flavonoids, polyphenols, and cannabidiol compounds, there are a variety of plant proteins, amino acids, and plant fibers in hemp leaves. At present, the extraction process commonly used at home and abroad is mainly based on organic solvent immersion. To improve the extraction efficiency, various auxiliary means are often used, such as ultrasonic wave, microwave, countercurrent extraction, centrifugal extraction, thermal reflux, etc., but these methods are inseparable from Organic solvents are used as extraction solvents. It can be seen from the methods reported so far that the extraction efficiency is generally higher when the temperature is relatively high, but at the same time, other components in the plant are also extracted successively, which brings difficulties to the subsequent separation and purification. Compared with other separation methods, bho extraction closed loop have many advantages: non-toxic, harmless, environmentally friendly, non-polluting, free from heat treatment, retaining the active components in the extract without damage or oxidation, large capacity, energy-saving, low operating cost, easy Processed product separation. 1lb passive closed loop extraction kit gently remove intoxicating cannabis compounds from plants without damaging the volatile terpenes in the flower buds. Compared to concentrates without these aromatic terpenes, BHO concentrates, such as live resins or terpene sauces, can retain higher than normal terpene content, giving them a richer, fuller flavor.

Closed-loop extraction:

Solvent extraction can be summarized in 4 steps:

1. The sample is immersed in boiling solvent during the immersion process.

2. Then automatically lower the level to move the solvent under the extraction sleeve. During the washing process, the condensed solvent flows through the sample and through the thimble to complete the extraction process.

3. The fourth step involves solvent recovery. Approximately 90% of the solvent used is collected in the internal recovery tank.

4. The final step is cooling the extraction cup containing the extract. Raise the cup to prevent burning. The extraction cup containing the extract is

Place in a drying oven, cool in a desiccator, and weigh to calculate the percent extract.

What is butane?

Butane is a light hydrocarbon that belongs to the same molecular family consisting of ethane, propane and methane. Butane is produced from crude oil extracted by breaking down organic matter buried deep in the ground. Specialty extraction companies use the purity and low boiling point of instrument-grade butane to extract cannabis more completely than other solvents such as carbon dioxide or ethanol.

Butane is a gas under standard conditions and requires extraction at above atmospheric pressure. After extraction, butane is relatively easy to purge from the resulting extract due to its lower boiling point. However, the biggest disadvantage of using butane to extract cannabinoids is safety. Butane is highly flammable, and its use has resulted in small explosions in small extractors. Additionally, there is concern that if the butane is not pure, undesirable and potentially toxic hydrocarbons may end up in the THC extract product.

Precautions when using butane:

First of all, butane is a highly flammable substance. When performing THC extraction, always pay attention to the abnormality of the instrument. If it is not handled properly, it may explode. So keep the butane properly;

Second, butane vapors can build up at lower levels (floors), and if butane vapors build up a lot during THC extraction, this mixed addition can create a lot of sparks and give you a big problem;

Third, inhaling a large amount of butane vapor can be fatal, so make sure that the bho extraction closed loop works in a well-ventilated place when extracting THC;

Zhengzhou Keda Machinery Instrument Equipment Co., Ltd. has rich experience in the production and use of closed-loop extractors. Contact us to help you choose the right model, as well as a range of services, people and advice.