-

WhatsApp

-

Email

Beer filtration and separation, beer filling. After the beer is fermented and matured, it needs to be clarified before it becomes a commodity to improve the appearance and stability of the beer; at the same time, in order to facilitate beer transportation, sales and consumption, product packaging is required: in order to extend the shelf life of the beer Bacterial treatment (such as heat sterilization or sterile filtration, etc.). Among them, the beer filtration and separation part mainly introduces the purpose, requirements, filtration principles and methods of beer filtration, and masters the form, operation and maintenance of commonly used filter machines.

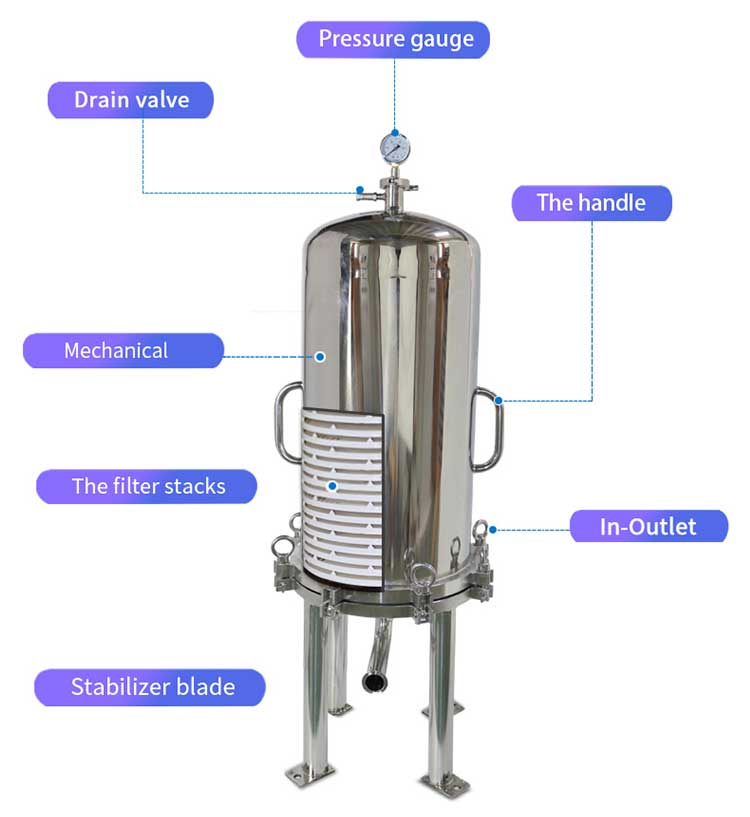

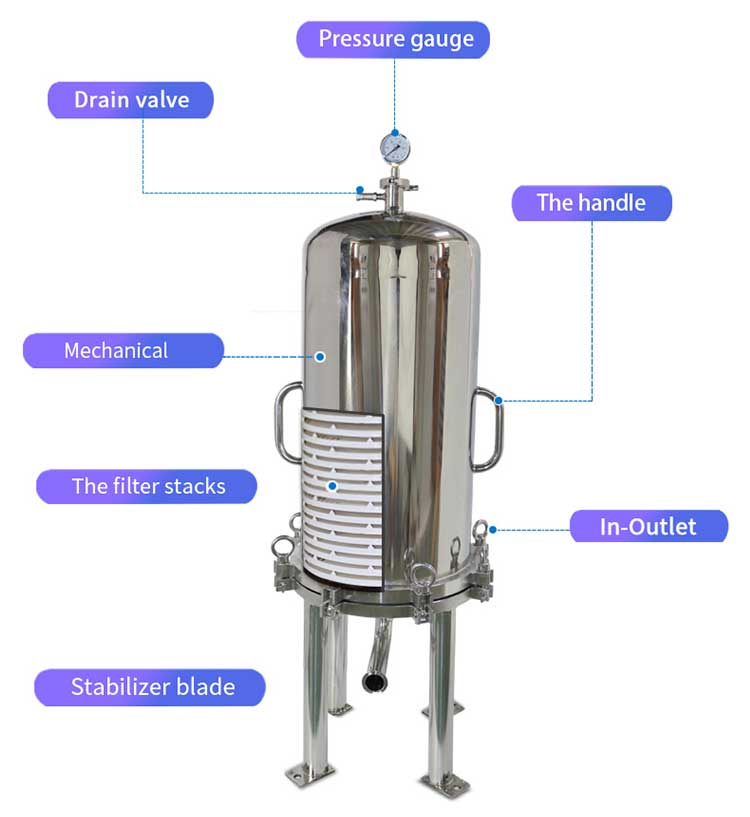

The vertical lenticular filter is the most suitable equipment for filtering microorganisms and solids of alcohol, syrup and beer.

1. Filtration and separation of beer

A. Purpose and requirements of filtering

After the fermentation of mature beer, although most of the protein and yeast have precipitated, there is still a small amount of material suspended in the wine, which must be clarified before packaging.

The purpose of beer filtration is:

a. Remove the suspended matter in the wine, improve the appearance of the beer, make the beer clear and transparent, and full of luster.

b. Remove or reduce the substances that make the beer appear turbid and precipitate (polyphenol substances and proteins, etc.), improve the colloidal stability of beer (non-biological stability).

c. Remove microorganisms such as yeast or bacteria to improve the biological stability of beer. The requirements for beer clarification are: large output, high transparency, small wine loss, less loss, less pollution, no oxygen absorption, and no influence on beer flavor.

B. Filtration principle and filtration method

The principle of beer filtration and clarification is that the large particles of solids such as microorganisms and condensed solids present in beer are separated by the blocking effect (or retention effect), depth effect (medium void trapping effect) and electrostatic adsorption of filter media. And make the beer clear and translucent. Commonly used filter media are diatomaceous earth, filter paper, microporous membrane and ceramic core.

a. Filtration principle

The principle of separating solid particles suspended in beer is:

1. Blocking effect (or retention effect)

The particles in the beer that are larger than the filter media voids cannot be hidden through the filter media voids. The hard particles will adhere to the filter media surface to form a coarse filter layer, while the soft particles will adhere to the filter media voids or even make the voids Clogging, reducing filtration efficiency and increasing filtration pressure differential.

2. Depth effect (medium void trapping effect)

The long and tortuous micropore channels in the filter media have a blocking effect on suspended particles. For the particles that are smaller than the gap of the filter media, they are trapped in the micropores of the media due to the effect of the micropore structure of the filter media.

3. Electrostatic adsorption

Some particles with smaller voids than filter media and high surface active polymer substances such as proteins, hop resins, pigments, etc., because of their different charge from the filter media, will be trapped in the filter media by electrostatic adsorption.

C. Filtering method

Beer filtration methods can be divided into filtration methods and centrifugal separation methods. Filtration methods include cotton cake filtration method, diatomite filtration method (specifically can be divided into plate and frame diatomite filtration method, horizontal blade type and vertical blade type diatomite filtration method, candle type or ring type diatomite filtration method ), Plate filtration method (fine filter machine method) and membrane filtration method (microporous membrane filtration method and other wrong filtration method). One of the most commonly used is

Diatomaceous earth filtration method.

1. Commonly used combinations of beer filtration are:

Conventional

Composed of diatomite filter and fine filter "plate filter", it is the most commonly used filter combination in beer production. Some companies only use diatomite filter to filter once during the peak production season, it is difficult to ensure the filtration effect.

Compound

It is composed of beer centrifugal clarifier, silicon source soil filter and fine filter, and some also adds a bag filter between the silicon fore soil filter and the fine filter or between the drainage and filling machine (to prevent Diatomaceous earth or short fiber into beer).

Sterile filter

It consists of beer centrifugal clarifier, diatomite filter, belt filter, fine filter and microporous membrane filter. Mainly used to produce pure

Draft beer, canned or barrel draft beer, and bottled draft beer.

2. Deep filtration

It refers to the filtration of beer according to the size of different particle diameters. The filter is gradually carried out from large to small pores, to avoid the small particles blocking the filter channel and reduce the filtering amount of large particles, which can also improve the filtration effect. In addition to the beer centrifugal separator and diatomite filter, a number of filter units with large to small pore sizes should be used together with a pore size of 0.5 ~ 3μm. Through deep filtration, the clarity of beer is continuously improved, and the turbidity level of the product can be determined according to different requirements, and can even meet the requirements of sterile filtration. Deep filtration is one of the development directions of beer filtration.

3. Changes after beer filtration

The interception, depth effect and adsorption of beer through the filter medium make the beer change regularly during filtration: slightly clear, clear, very clear, clear, slightly clear, loss of light or blockage. The effective filtration amount of beer refers to the number of beer that can be filtered per unit of filter medium under the condition that the beer reaches a certain degree of clarity (expressed in turbidity units). After filtration, the following changes will occur:

(1) The decrease in chroma is generally reduced by 0.5 to 1. OEBC units. The reason for the decrease is that some of the pigments and polyphenols in the wine are adsorbed by the filter medium and reduce the chroma.

(2) Decrease in bitter taste The bitter substance is reduced by 0.5 to 1.5 BU, which is caused by the adsorption of the bitter substance in the filter medium.

(3) Decreased protein content The protein content of beer after filtering with diatomite decreased by about 4%. In addition, the addition of silica gel will also adsorb part of the polymer nitrogenous substances.

(4) Decreased carbon dioxide content C0 after filtration: the content is reduced by 0.02%, mainly due to changes in pressure and temperature and the resistance of pipelines and filter media.

(5) The increase of oxygen content and the change of concentration of wine pumping, running water or using compressed air as the back pressure of a sake tank will increase the oxygen content in beer. At the same time, the concentration of beer will change due to running water, top water and simultaneous filtering.

Beer filtration equipment includes cotton cake filter, diatomite filter, microporous membrane filter and beer centrifuge.

The vertical lenticular filter is the most suitable equipment for filtering microorganisms and solids of alcohol, syrup and beer.

KDGDB Lenticular Filter is a new type of stacks filter, can be used in place of diatomite filter, for tiny impurities in varied kinds of liquid filtration, clarification, purification.

The structure is designed and manufactured according to the health level, internal is no dead corner and mirror polishing, it ensure no residual liquid and easy to clean.

KDGDB Lenticular Filter Housing can maximal install 4 filter stacks, it can fit for big flow requirements.

You can click the link below to view the complete lenticular filter housing information: https://kdlabequipment.com/lenticular-filter/Lenticular-Filter.html