-

WhatsApp

-

Email

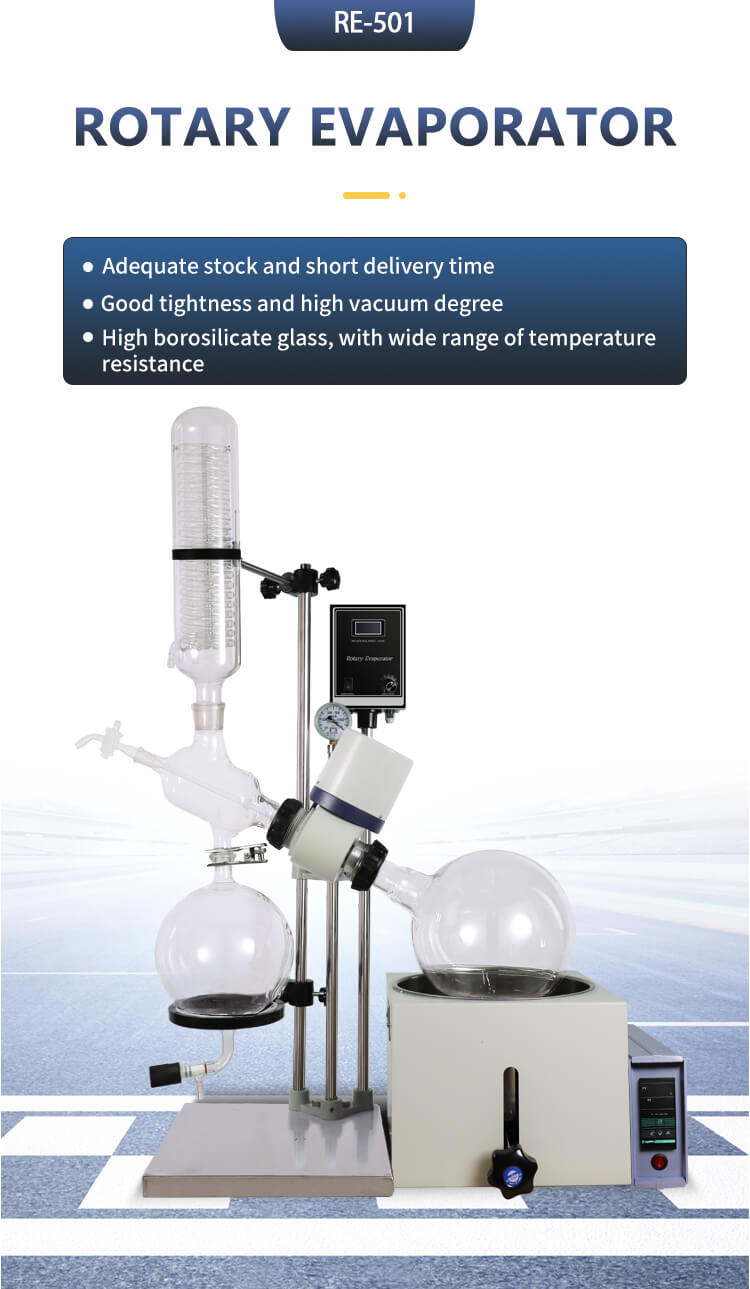

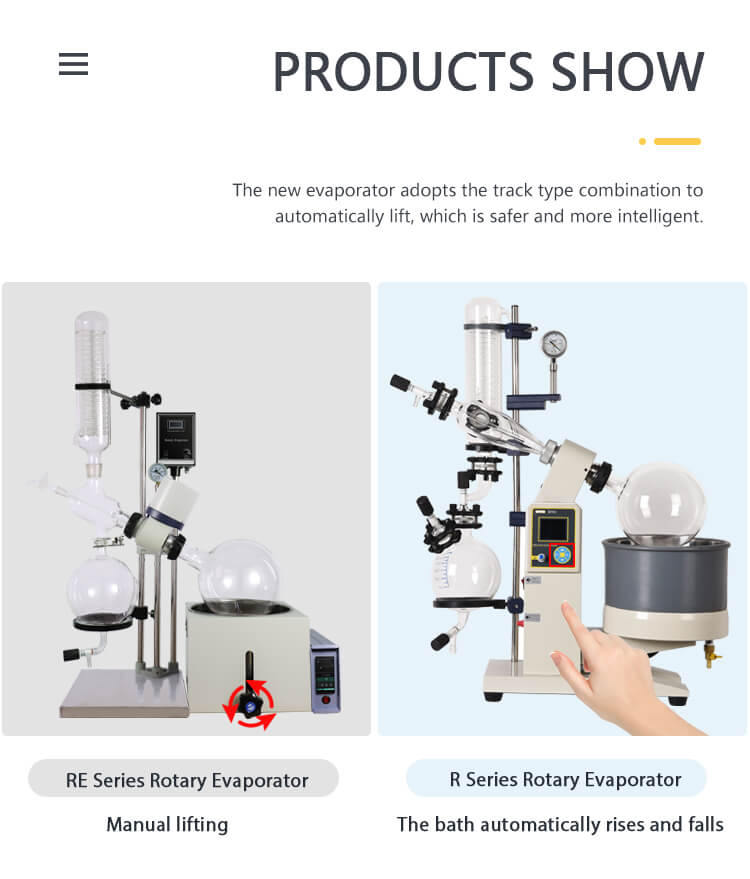

Lab evaporators play a pivotal role in various scientific and industrial applications, enabling efficient separation of solvents and substances from complex mixtures. Among these, the 5L rotary evaporator stands out as a versatile and essential tool for laboratories. This article delves into the features, applications, and benefits of 5L rotary evaporators, showcasing their significance in modern research and production processes.

Introduction to 5L Rotary Evaporators

A 5L rotary evaporator is a type of lab evaporator designed to facilitate gentle and efficient evaporation of solvents from samples. The distinctive feature of a rotary evaporator is its rotating flask, which provides a larger surface area for solvent evaporation, enhancing the efficiency of the process. This compact and versatile device finds applications in diverse fields, including chemistry, pharmaceuticals, biotechnology, and more.

Advantages and Features of 5L Rotary Evaporators

5L rotary evaporators come with a range of features that make them indispensable in laboratories:

Precise Temperature Control: These evaporators offer precise control over temperature, preventing excessive heat that could potentially damage sensitive samples.

Variable Rotation Speed: The adjustable rotation speed allows researchers to optimize the evaporation process according to the specific requirements of the sample, leading to higher efficiency and better results.

Vacuum System: A built-in vacuum system reduces the boiling point of solvents, enabling evaporation at lower temperatures and preventing sample degradation.

Digital Display: Modern 5L rotary evaporators often come equipped with digital displays, making it easier to monitor and adjust crucial parameters in real-time.

Safety Features: Many models are equipped with safety features such as automatic shut-off mechanisms in case of overheating or low water levels, ensuring a secure working environment.

Applications and Case: Concentration of Aromatic Compounds

One compelling application of a 5L rotary evaporator is the concentration of aromatic compounds from plant extracts. A case study conducted by a research team at a pharmaceutical company demonstrates the effectiveness of a 5L rotary evaporator in this context. The researchers aimed to isolate essential oils from a plant extract containing various aromatic compounds.

Initially, the extract contained a solvent with a density between 0.5% and 3%. Conventional distillation methods proved inefficient due to the sensitivity of the aromatic compounds to high temperatures. By employing a 5L rotary evaporator, the researchers were able to maintain precise temperature control, preventing the degradation of the essential oils. The vacuum system further facilitated the evaporation process, reducing the boiling point of the solvent and minimizing the risk of thermal damage.

As a result of this study, the research team successfully concentrated the aromatic compounds while preserving their integrity. This achievement highlighted the significance of 5L rotary evaporators in maintaining the quality of delicate substances during distillation processes.

Operating a 5L Rotary Evaporator: Best Practices

To ensure optimal results while operating a 5L rotary evaporator, several best practices should be followed:

Sample Preparation: Properly prepare the sample by filtering out impurities and ensuring uniformity in composition.

Flask Loading: Load the sample into the round-bottom flask while considering the flask's capacity and the required concentration.

Vacuum Control: Adjust the vacuum level to match the boiling point of the solvent, facilitating efficient evaporation.

Temperature Adjustment: Set the appropriate temperature to prevent overheating and sample degradation.

Rotation Speed: Optimize the rotation speed based on the sample's characteristics and the desired evaporation rate.

Collection of Condensed Solvent: Ensure proper collection of the condensed solvent to avoid cross-contamination and maximize recovery.

Enhancing Efficiency: Accessories and Techniques

To further enhance the efficiency of a 5L rotary evaporator, researchers often utilize various accessories and techniques:

Cold Traps: Cold traps prevent solvent vapors from reaching the vacuum pump, prolonging the pump's lifespan and preventing contamination.

Anti-Bumping Granules: These granules promote smooth boiling by preventing bumping, which can cause uneven evaporation.

Parallel Evaporation: Using multiple rotary evaporators simultaneously increases throughput, ideal for high-volume laboratories.

Solvent Recycling: Employing solvent recycling systems reduces waste and operational costs.

Future Trends in Lab Evaporation Technology

The field of lab evaporation is continuously evolving, and several trends are expected to shape the future of rotary evaporators:

Automation: Increased automation will streamline processes, allowing researchers to program and monitor evaporation remotely.

Integration with Analytics: Integration with analytical instruments will enable real-time monitoring of concentration levels.

Energy Efficiency: Future models will likely focus on energy-efficient designs to reduce environmental impact.

In conclusion, 5L rotary evaporators have emerged as essential tools in laboratories, enabling efficient solvent evaporation while maintaining the integrity of delicate compounds. Their precise temperature control, variable rotation speed, and vacuum systems make them versatile and indispensable for various applications, from pharmaceuticals to food science. As technology continues to advance, these devices will play an increasingly important role in shaping the future of laboratory evaporation processes.