The cbd crystallization reactor is mainly used for stirring and mixing materials in pharmaceuticals, cooling and freezing, and crystallization of finished products. The cbd crystallization reactor is also widely used in the dairy industry, food, chemical, beverage and other industries. It is a crystallization equipment that requires chilled water or refrigerant water to cool down sharply in the interlayer after the material is mixed and reacted. The key links are the size of the interlayer area, the structure of the agitator and the form of material outlet, high-precision polishing in the tank, and no dead ends in the tank. requirements to meet the process conditions of use. Opening of reactor cover: 10L-20L with total openings (stirring opening 50,flange liquid feed inlet DN25,high vacuum )

CBD crystallization reactor configuration:

This series of cbd crystallization reactors is made of imported 316L or 304 stainless steel, the inner wall is electrolytic mirror or mechanically polished, the outer wall is 304 fully welded structure for heat preservation, and the outer surface is mirror or matte. A 0.22um hydrophobic breather filter is installed on the crystallization tank. The crystallization tank can withstand high temperature sterilization at 121°C and is equipped with a sanitary pressure gauge. The external connection of the tank adopts sanitary quick-open joints. Equipped with temperature monitoring device, 2 sight glasses, cleaning ball, nitrogen inlet, PH meter port, thermometer port and other interfaces. The shaft seal adopts a special sanitary mechanical seal to ensure that the material is not polluted. The crystallization tank can adopt a frequency conversion speed regulating device, and the stirring shaft speed can be adjusted in a large range.

Technical features of cbd crystallization reactor:

The company has rich design and manufacturing experience for different process requirements, and the equipment produced fully meets the GMP verification requirements.

1. The equipment adopts the anchor stirring structure, which can increase the heat exchange area, improve the heat exchange efficiency, increase the crystallization capacity, and facilitate the feeding and discharging.

2. Steam or refrigerant can be passed into the jacket of the equipment to keep the material at the optimum temperature, which has the advantages of high efficiency and convenient operation.

3. A 0.22um hydrophobic vent filter is installed on the equipment, and the tank can withstand high-temperature steam sterilization and is equipped with a sanitary pressure gauge.

4. The outside of the equipment tank adopts a sanitary quick-open interface. Equipped with thermometer, 2 sight glasses, cleaning ball and nitrogen inlet and other interfaces.

5. The equipment is sealed with a special sanitary mechanical seal to ensure that the material is not polluted.

6. The equipment adopts stepless speed regulation device, the stirring shaft speed can be adjusted in a large range, the stirring is uniform, and the crystals are uniform.

CBD crystallization reactor Features:

1. 5-6 openings on reactor cover, which can be increased or decreased according to customer requirements.

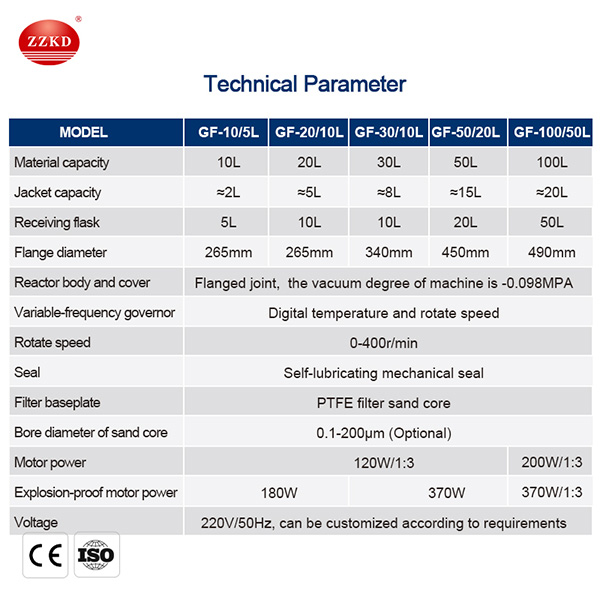

2. Optional reactor capacity(100mL to 100L).

3. Stainless steel frame, with good preservative effect.

4. PTFE bottom valve, with design of no dead angle and thorough feeding.

5. Filter base plate aperture 0.1-200μ M optional.

Advantages of cbd crystallization reactor:

1. The equipment adopts the hollow ribbon stirring structure, which can increase the heat transfer area, improve the heat transfer efficiency, increase the crystallization capacity, and facilitate the feeding and discharging.

2. Steam or refrigerant can be passed into the jacket of the equipment to keep the material at the optimum temperature, which has the advantages of high efficiency and convenient operation.

3. A 0.2 μm hydrophobic ventilation filter is installed on the equipment, and the tank can withstand high-temperature steam sterilization, and is equipped with a sanitary pressure gauge.

4. The outside of the equipment tank adopts a sanitary quick-open interface. Equipped with thermometer, 2 sight glasses, cleaning ball and nitrogen inlet and other interfaces.

5. The equipment is sealed with a special sanitary mechanical seal to ensure that the material is not polluted.

6. The equipment adopts stepless speed regulation device, the stirring shaft speed can be adjusted in a large range, the stirring is uniform, and the crystals are uniform.

CBD crystallization reactor accessoriesdetails:

Handwheel lifting motor.

Snake condenser, used for condensing reflux.

Collection bottle to collect the liquid separated by filtration.

PTFE filter bottom plate, removable and replaceable filter sand core.

CBD crystallization reactor warning:

1. Do not run at high speed under no load.

2. The operating temperature range is as low as - 80 ℃, and the high temperature is recommended to be 250 ℃.

3. Pressure range in reactor: -0.1MPA to 0MPA.

4. It is recommended to gradually raise and lower the temperature, and the sudden drop temperature difference is 100 ℃.

The cbd crystallization reactor is widely used in the reaction, evaporation, synthesis, polymerization, saponification, sulfonation, chlorination, nitration and other process pressure in chemical industry, food, coating, hot melt adhesive, silica gel, paint, medicine, petrochemical production Containers, such as reactors, reaction kettles, decomposition pots, polymerization kettles, etc. The crystallization reactor is mainly composed of four major parts: inner tank, jacket, stirring device, and support seat (with insulation structure can be used according to process requirements).