-

WhatsApp

-

Email

The lab small glass reactor is a smart glass reactor equipment. It has an intelligent temperature controller and speed regulator.

Temperature control controller: The temperature can be accurately controlled to ±1 °C.

Speed Regulator: It is a stepless speed regulator that you can set freely.

Features

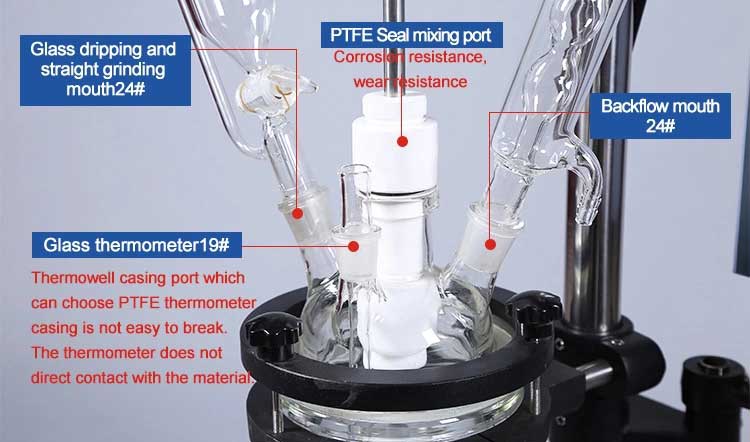

- Made of PTFE material, no leakage, corrosion resistance.

- GG17 high borosilicate glass owns good chemical and physical properties, big bottle mouth, hand-in cleaning.

- Overall stainless steel frame structure, compact and solid, stable and reliable without shaking when stirring.

- With brake casters, convenient and reliable for moving.

- Glass discharge valve without a dead corner, solid/liquid material can be easily released from the bottom.

- The LCD display, easier and more convenient to measure temperature.

Detail

For the perfect use of the entire glass reactor system you may need the following equipment

- High and low-temperature machine

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | S-3L Jacketed Glass Reactor |

| Stirring Power(W) | 60 |

| Stirring Speed(rpm) | 0~600(max.1300) |

| Stirring Shaft Diameter(mm) | 12 |

| Reaction Flask Capacity(L) | 3 |

| Voltage(V/Hz) | 220 50/60 |

| Motor Torque(g/cm) | 2400 |