-

WhatsApp

-

Email

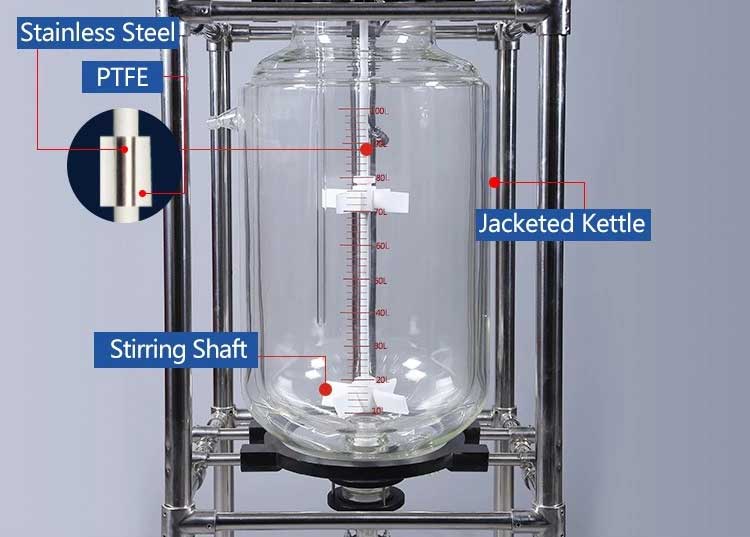

Large double-layer glass reactor | The mechanical components of the 100l jacketed glass reactor use stainless steel and aluminum alloy parts. The material discharged from the glass reactor has a flange opening and a PTFE valve. There is no dead angle inside the container, which can be removed. Convenient for the discharge of solid materials.

Features

- The glass reactor system uses an efficient condenser to ensure a high recovery rate.

- The glass interlayer interface is added with hot oil, through the loop, it can do reaction under the condition of high temperature; the glass inter layer interface added with cooling fluid can carry on reaction under the condition of low-temperature.

- Double-layer glass reactor discharged material has flanged opening and PTFE valve, without dead angle inside the container, it can be demounted to facilitate the discharge of solid materials.

- The double-glazed reactor system has a reasonable structure.Stainless steel and aluminum alloy parts for mechanical parts,Electrical component parts: The main components use imported equipment.

- Double-layer glass reactors cover opening design: constant pressure hopper opening (or as inlet), condensation reflux inlet, thermometer bushing opening, solid feeding opening (or an outlet) and mixing opening.

- The range of the glass reactor stirring rate is 10-1100 r/min.

Detail

|

- Machine Parts Gear Motor 1. International standard copper wire. 2. High efficiency, long running time, good stability, no noise. 3. Standard gears, no gap and abrasion resistance. 4. CE certification. |

|

- Main Features Stirring Shaft The stirring shaft is made of stainless steel and coated by PTFE. Stainless steel supports high strength and PTFE avoids material being contaminated |

|

|

- Machine Parts Easy to disassemble PTFE material with no dead ends. solid/liquid material can be easily released from the bottom. |

For the perfect use of the entire glass reactor system you may need the following equipment

- High and low-temperature machine

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

| Model | S-100L Jacketed Glass Reactor |

| Stirring Power(W) | 180 |

| Stirring Speed(rpm) | 0~600(max.1300) |

| Stirring Shaft Diameter(mm) | 15 |

| Reaction Flask Capacity(L) | 100 |

| Voltage(V/Hz) | 220 50/60 |

| Motor Torque(g/cm) | 3000 |

| Note | 304All Stainless Steel Frame |