-

WhatsApp

-

Email

The 100l jacketed glass reactor has a glass thickness of 5-7 mm and is highly resistant to acids and bases. The borosilicate glass used has a low expansion coefficient and can guarantee the service life of the equipment.

The expansion coefficient of borosilicate glass for 100L double-layer glass reactor is 3.3, a kind of glass with sodium oxide (Na2O), boron oxide (B2O3) and silicon dioxide (SiO2) as the basic components. The content of borosilicate in this glass composition is relatively high, boron: 12.5-13.5%, silicon: 78-80%. Therefore, this type of glass is called high borosilicate glass. It belongs to Pyrex glass in borosilicate glass. It is characterized by a small coefficient of thermal expansion, and is not easy to burst under sudden temperature changes at high temperatures; it is acid-resistant, alkali-resistant, water-resistant, and has excellent corrosion resistance. It has good thermal stability, chemical stability, and electrical properties. Thermal shock resistance, good mechanical properties, high service temperature, high hardness and other characteristics, so it is also called heat-resistant glass, heat-resistant shock glass, high-temperature resistant glass, and it is also a special fire-resistant glass.

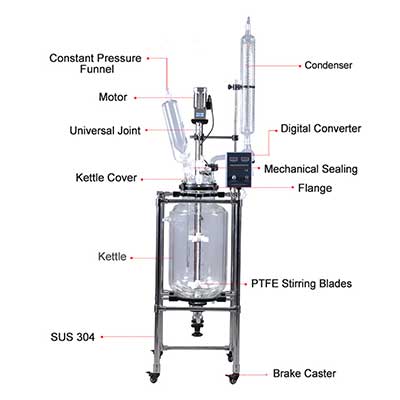

100l jacketed glass reactor features:

1. This product is more advanced and more ideal and practical in our company at home and abroad. The triple elastic design of the support frame ensures the reaction operation of heavy loads and is compatible with the safety of lifting and changing.

2. Made of borosilicate glass (GG17), it has excellent physical and chemical properties.

3. It can be used in a large temperature range from high temperature 200°C to low temperature -80°C.

4. The surface of the bracket is sprayed with Teflon, which is resistant to strong corrosion and maintains the aesthetics and longevity of the whole machine. (also optional spray)

5. Advanced frequency conversion speed regulation, frequency conversion controller, internal components have vacuum coating protection, corrosion resistance, optional full explosion-proof, safe and reliable.

6. The kettle body has double layers, and the heat source and cooling liquid are used in the middle of the interlayer to provide the needs for the reaction. Three-layer kettle body, the first layer is a vacuum interlayer kettle body for insulation, and the second layer provides heat and cold for the reaction. The fully transparent reaction bottle can make the reaction process clear at a glance.

7. The polytetrafluoroethylene (PTFE) component is sealed and specially designed to maintain the best vacuum degree (about -0.098mpa) of similar products in the market. The discharge valve can release concentrated liquid and trace solid materials, leading the country.

8. The jacket pressure control device is a new technology for the protection of the kettle body of the company, which makes the work safer and more reliable.

9. The kettle cavity and interlayer sleeve are designed to have no dead angle, anti-corrosion, and pollution-free structure.

10. After the reaction, the heat transfer medium can be completely removed without effusion.

11. The structure of the whole product is scientific, beautiful and practical, leading domestically.

12. High-performance PTFE combination seal frequency conversion stirring.

100l jacketed glass reactor use characteristics:

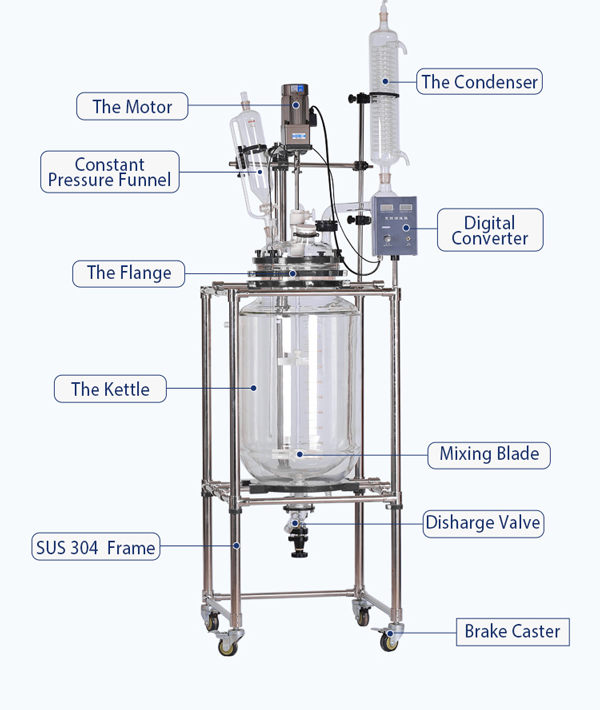

The speed-regulating glass reactor is mainly used for experiments such as material synthesis, distillation, and concentration. The kettle body structure is divided into three types: single-layer, double-layer and three-layer. According to the need, the inside of the kettle can be pumped to a negative pressure state to meet the experimental conditions. Control the uniform dropping of materials by adjusting the constant pressure funnel or the regulating valve on the feeding bottle. The heat exchange function of the condenser is used to distill and recover the reaction product. The body of the double-layer speed-regulating glass reactor has two layers, inner and outer. By injecting a certain temperature of circulating fluid into the interlayer, the temperature of the material in the kettle is adjusted. The three-layer speed-regulating glass reactor has two layers of glass jacket. The inner jacket is used to feed circulating liquid at a certain temperature to adjust the temperature of the material in the kettle. The outer jacket is evacuated to a vacuum state by a vacuum pump to realize the heat preservation function.

1.High borosilicate glass material, with excellent physical and chemical properties.

2.Can be used in the range of high temperature (200°C) to low temperature (-80°C).

3.It can work under normal pressure and negative pressure, and the vacuum degree can reach 0.095MPa.

4.The pressure range that the kettle can withstand: -0.1MPa~0MPa.

5.Cock or discharge valve made of Teflon+FV rubber; "O" ring with tetrafluoroethylene protective layer.

Grouped equipment:

1.Circulating water type multi-function vacuum pump

2.Diaphragm vacuum pump

3.Rotary vane vacuum pump

4.High temperature circulating water/oil bath

5.Low-temperature coolant circulation pump

6.High and low-temperature machine

| Model | S-50L Jacketed Glass Reactor |

| Stirring Power(W) | 120 |

| Stirring Speed(rpm) | 0~600(max.1300) |

| Stirring Shaft Diameter(mm) | 12 |

| Reaction Flask Capacity(L) | 80 |

| Voltage(V/Hz) | 220 50/60 |

| Motor Torque(g/cm) | 1800 |

| Note | 304 All Stainless Steel Frame |

1.What's the max temperature?

Usually, the high borosilicate glass can withstand over 300℃ and the PTFE stirring bar can withstand about 200℃.2.How do I choose a vacuum device for my glass reactor?

If your glass reactor is a small glass reactor equipment, such as a 1L, 2L, 3L, 5L, 10L glass reactor vessel. You can choose from benchtop circulating water vacuum pumps, rotary vane vacuum pumps, and diaphragm pumps.If your glass reactor equipment is a 20L, 30L, 50L, 80L, 100L large glass reactor, you can choose a vertical circulating water vacuum pump to meet your experimental needs.