-

WhatsApp

-

Email

The stainless steel chemical reactor has the characteristics of rapid heating, high temperature resistance, corrosion resistance, sanitation, no environmental pollution, no automatic heating of the boiler, and convenient use. It is widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food, and other industries. To complete the processes of sulfidation, nitration, hydrogenation, hydrocarbonation, polymerization, condensation, etc., it is based on the premise that the reaction materials are fully mixed. For physical changes such as heating, cooling, and liquid extraction and gas absorption, stirring devices are required. Get good results, and can design and process outer coil reactors for customers.

Featrues

- Material: SUS304 or S.S.316L.

- Mixing type: anchor type, frame type or paddle type.

- Mixing structure: cycloid pinwheel reducer or stepless reducer.

- Sealing equipment: Mechanical sealing.

- Heating or Cooling: jacket, half-pipe or coil pipe.

- Heating way: steam heating, electrical heating or heat conduct oil.

Detail

Stainless steel reactor is suitable for:

Stainless steel reactors are widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food, and equipment used to complete sulfur, nitration, hydrogenation, hydrocarbonation, polymerization, condensation and other processes.

After sale

Package

Transport

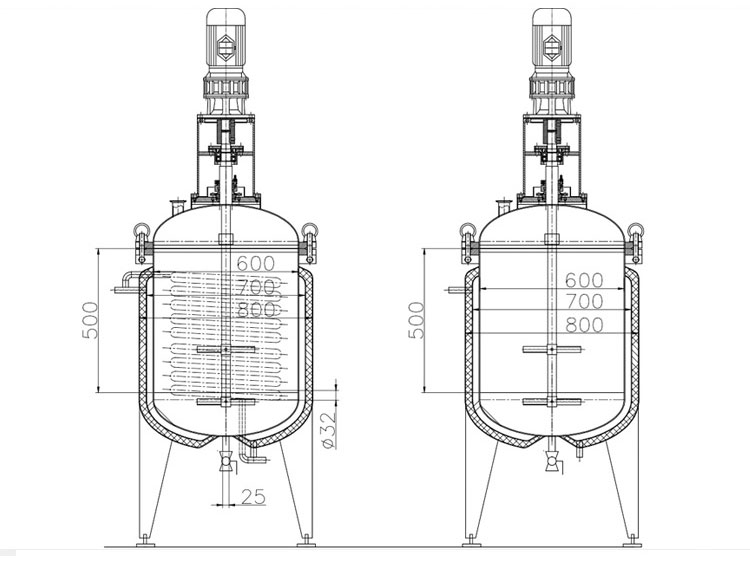

1. Composition of stainless steel reactor.

The stainless steel reactor equipment is composed of a tank body, a tank lid, a stirring paddle, a feeding port, a discharging port and a discharging valve.They are all made of imported stainless acid-resistant steel 304. The inside and outside of the tank are polished. The tank has stirring blades.There is a reducer on the top to drive the stirring paddle;Can be disassembled and cleaned. The tank lid is openable, can be disassembled and cleaned. Two additional inlets can be connected to the pipeline to facilitate the connection of various ingredients. There is a discharge outlet below. After mixing, rotate The ball valve handle can be discharged at 90 °, and it will be closed immediately after discharging.2. How to install stainless steel reactor?

The stainless steel chemical reactor vessel has three feet, and the inlet and outlet can only be installed until the horizontal line is perpendicular to the reducer. When connecting the power, pay attention that the stirring pulp should rotate in the direction of the needle, and must not be reversed.3. Maintenance of stainless steel reactor.

The reactor should be washed with hot water before use, and then sterilized with steam.Various materials enter the tank through the material tube fixed on the tank lid, or the tank lid is opened and poured in. The input materials should not be filled too much, so as to prevent the materials from splashing while being stirred, causing unsanitary or loss of environment.Put it into the tank according to the proportion, and then start the motor after it is full, usually 3 to 5 minutes, stir well, open the ball valve to discharge, and wait for the next feeding.

After the mixing is completed, the remaining materials in the tank are exhausted. Rinse with warm water as soon as possible, brush away the attached materials, and then thoroughly wash the inner wall of the container with 40 ° C-50 ° C hydrogen peroxide and rinse with water until the next use.

Pay attention to the working condition of the entire equipment and the reducer. When the lubricant of the reducer is insufficient, it should be replenished in time and the oil should be changed every six months (40 # machine oil).When the equipment is not in use, be sure to wash the inside and outside with warm water, do not rinse with salt water to avoid corrosion, scrub the tank frequently, keep the appearance clean, and the inner container bright, to achieve the purpose of durability.