-

WhatsApp

-

Email

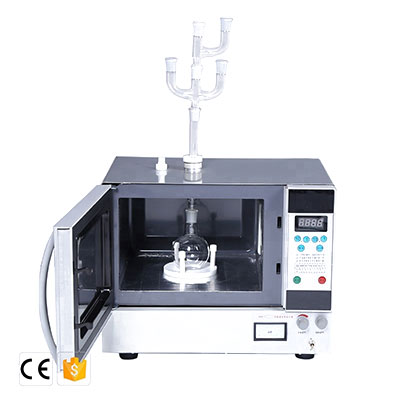

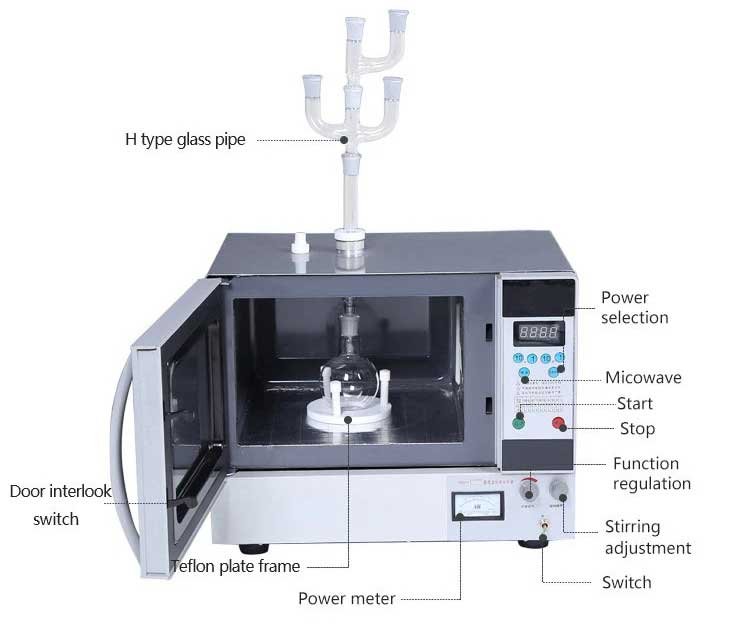

Microwave pyrolysis reactor is a type of microwave chemical reactor, its temperature control range: 0 ~ 300 ℃, temperature control accuracy: ≤ ± 0.5 ℃. Can pyrolyze some special substances.

WBFY-205 microwave reactor uses a unique frequency conversion air cooling function to keep the temperature inside the cavity uniform. Can better pyrolyze substances.

Features

- Large-screen LCD display: real-time working time, real-time power, real-time temperature, and real-time page turning to display the temperature curve.

- Parameter controlling section operation with high sensitivity of the touch screen, all parameters can be programmed and stored in five groups of experimental data;

- With a 10-inch ultra-thin, ultra-high-definition, multi-function LCD large screen display, real-time display of the sample working status;

- Using high-precision probe type PT1000 sensor for temperature measurement, real-time detection of reaction temperature, accurate control of reaction process temperature; control range: 0 ~ 300 ℃, temperature control accuracy: ≤ ± 0.5 ℃;

- Using a unique frequency conversion air cooling function to keep the temperature in the cavity uniform;

- Working time: continuous working, adjustable between 0 ~ 999min;

Detail

Use of microwave chemical reactor:

Chemical Microwave Reactors apply microcomputer technology and unique technology of microwave adjustment, realizing microwave power continuously adjustable, good repeatability. For experiments that require microwave assisted catalytic reaction conditions, especially for those who require a smaller microwave power and who wish to maintain continuous microwave radiation chemistry experiments, its scientificity and practicability are ideal to play.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1.The working method of microwave reactor system.

- Dry matter baking: Moisture dry materials (such as silicone tube dehumidification) can be directly placed in a glass turntable for baking.After the work is completed, the glass turntable must be cooled before cleaning or put in water to prevent the turntable from bursting.- Tube sealing experiment: From the safety of microwave ovens and operators, the following points must be carefully observed:

- Known to produce gas reactions, do not do tube sealing experiments;

- The tube must be made of pressure-resistant 95 material glass; the amount of reactive material must be strictly controlled.

- The sealed tube is best placed in a plastic microwave box and placed on a glass turntable to start the reactor.

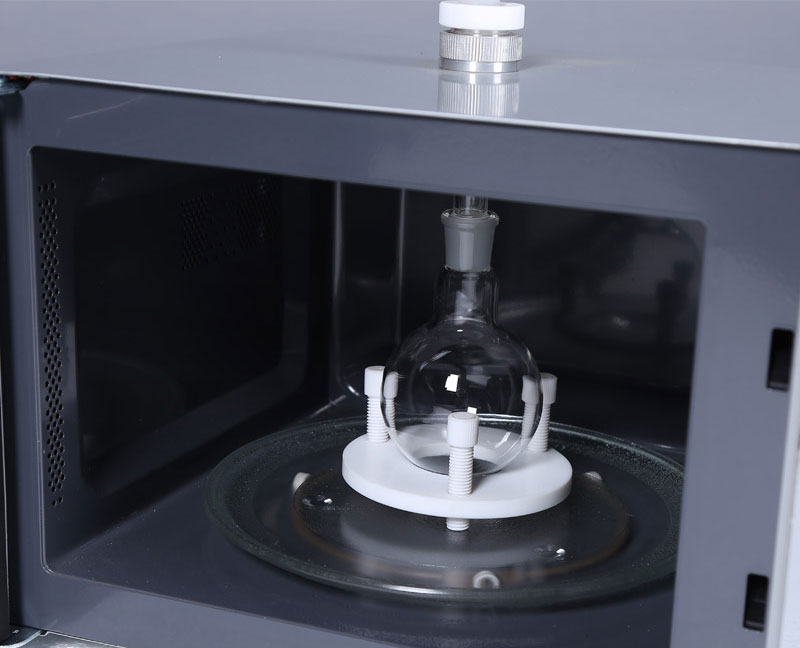

- Liquid or liquid / solid phase chemical reaction: First remove the glass turntable and ring.

- If the amount of reactants is small and there is no need to stir, a 50ml or 100ml flask can be used, and the polytetraethylene tray is placed in the center of the furnace bottom, and then a suitable reflux device is arranged directly above the furnace top.

- Solid-phase chemical reactions: reactors and working methods can be flexibly arranged according to the needs of the reaction, but the following principles must be followed:

- Gas-generating reactions, especially those that produce corrosive and irritating gases, can easily cause damage to circuits and computer boards. A return device should be installed and drawn out of the furnace through a duct.

- Dielectric constants and dielectric losses of reactants and products are different. The absorption of microwaves in the microwave field will be different. Local temperature differences often occur over a period of time. Therefore, solid-phase reactions often need to be stirred and shaken in the middle of the process. And choose a lower power range to make the reaction as uniform as possible.

- No chemical reaction in a microwave reactor is allowed in an open container, let alone in a closed container. The former may cause splash pollution to the cavity; the latter may cause explosion.

2. How to choose the working environment of the microwave pyrolysis reactor?

-Must be placed horizontally. The top reflux device or liquid adding device should be fixed with an iron frame for experiments. No other objects should be placed within 15cm of the back vent. It is not allowed to remove the support of the chemical reactor equipment.-The ideal power supply is a regulated power supply. If there is no regulated power supply, there should be a dedicated power supply line, not in line with other large electrical equipment.The line must be well grounded, and a fuse above 8A should be used.