-

WhatsApp

-

Email

The mini freeze dryer machine uses the company's unique point heating curve calculation method to realize the heating function on the mini freeze dryer, with more stable temperature rise, no overshoot, and more accurate temperature control. Under the premise of ensuring the utilization of laboratory space, a high-quality freeze-drying environment is realized with the most compact instrument structure design (normally unloaded -56°C, optional -80°C compressor). The mini freeze dryer has rich functions, easy operation, intelligent storage, data management and other functions.

Functions of mini freeze dryer machine components:

1. Overall performance: compact structure, powerful function

• The instrument is compact in design and small in size, easy to place and carry

• Imported compressor, stable and efficient, intelligent control, powerful

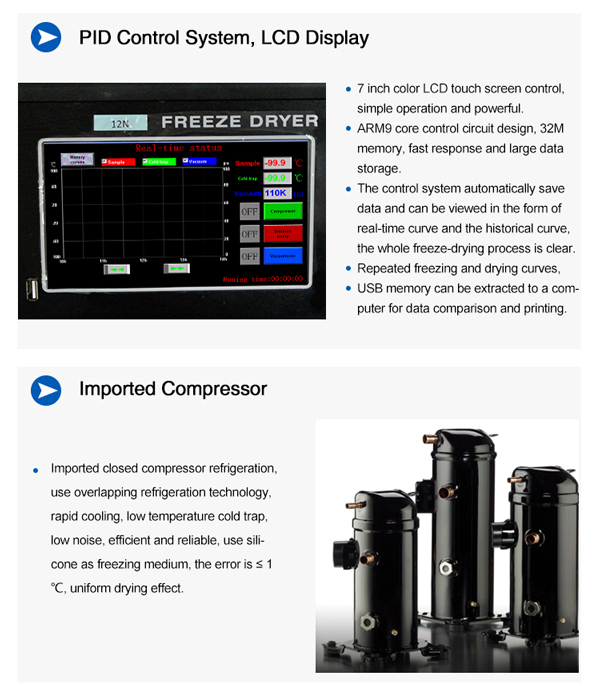

2. Control system: intelligent control, true color display

• 7-inch true color LCD touch screen, ergonomic design

• Important parameters (cold trap temperature/sample temperature/vacuum degree/baffle temperature, etc.) at a glance

• Industrial-grade embedded operating system, fast operation response, large amount of stored data

• Freeze-drying data is automatically saved, real-time view, historical reappearance, and the freeze-drying process is clear and controllable

• Support storage of multiple sets of freeze-drying curves, U disk copy, PC browsing, and printing

• There are 36 freezing curve schemes to choose from, each scheme contains 40 segments

• Temperature control setting to realize the record of freeze-drying process parameters of various materials

• Multi-layer permission setting, convenient for device management

• It has the function of automatically saving the freeze-dried data when the power is off

• With automatic alarm function for high room temperature

3. Refrigeration system: rapid cooling, clearly visible

• Imported brand compressors are used for refrigeration, with rapid refrigeration and low cold trap temperature

• Optional -80°C compressor for better cooling effect

4. Heating system: safe, efficient, stable and intelligent

• Use 36V safety voltage silicone rubber electric heating plate as heating element

• The partition temperature is adjustable and controllable, which can be used to explore the pilot test and production process

• Using PID intelligent heating method, the temperature control is more accurate, the temperature rise is more stable, no overshoot, and the temperature control is more precise

5. Drying room: transparent and sealed, anti-corrosion and reliable

• Colorless and transparent one-time injection molding polycarbonate drying chamber

• Corrosion-resistant, non-fragile, non-adhesive, high transparency, strong airtightness, clear and intuitive samples

• Can observe the whole process of freeze-drying

• Equipped with an inflation valve, which can be filled with dry inert gas

6. Vacuum system: vacuum controllable, intelligent protection

• The temperature of the cold trap can be set, and the vacuum pump will only be turned on when the temperature is lower than the set value, so as to protect the service life of the vacuum pump

• Vacuum pump oil mist filter is optional

• Optional automatic vacuum differential pressure valve to prevent oil back suction

Main features of mini freeze dryer machine:

1. Vertical design, compact structure, small space occupation.

2. Beautiful appearance, ergonomic design, easy operation.

3. Imported hermetic compressor, efficient and reliable, low noise.

4. Double compressor cascade refrigeration, mature technology, low temperature.

5. The cold trap has a large opening and has a sample pre-freezing function.

6. The cold trap is made of all stainless steel, and there is no coil in the cold trap, which is smooth and corrosion-resistant.

7. The design of the guide tube increases the effective area of the cold trap and enables rapid freeze-drying.

8. Inflatable valve, can be filled with dry nitrogen or inert gas.

9. Transparent plexiglass bell-type drying room, safe and intuitive.

10. International standard vacuum interface, which can be used with various vacuum pumps.

11. Digital display of temperature and vacuum.

12. Optional sample temperature display.

Features of mini freeze dryer machine:

1. The machine adopts compressor refrigeration, which has rapid refrigeration and low cold trap temperature.

2. The control system automatically saves the freeze-drying data, which can be viewed in the form of real-time curves and historical curves. The entire freeze-drying process is clear and clear.

3. The drying room adopts a colorless and transparent polycarbon drying room, the sample is clear and intuitive, and the whole process of freeze-drying can be observed.

4. The connection between the vacuum pump and the host adopts the international standard KF quick connector, which is simple and reliable.

5. This machine can store freeze-drying curves for many times, and use U disk to extract the data to the computer, and use the host computer software to browse, print and various options in the computer.

6. This control system has 36 freeze-drying curve scheme options, each scheme contains 40 temperature control settings, which can realize the freeze-drying process parameter recording of various materials, and directly call the corresponding scheme when a certain material is freeze-dried .

7. The company's unique point heating curve calculation method, the temperature rise is more stable, no overshoot, and the temperature control is more accurate.

8. The partition temperature is adjustable, controllable, explorable, pilot test and production process,

9. Equipped with manual and automatic two working modes, you can manually explore the freeze-drying curve of new materials

10. It can be controlled remotely, and it can be monitored at any time by using a mobile phone.

Optional functions of mini freeze dryer machine:

1. The eutectic point test function can grasp the better sublimation temperature of the material.

2. Vacuum degree control function to maximize heat transfer and prevent vacuum oil backflow system.

3. Two-machine cascade refrigeration system, mature technology, low temperature, used for -80 ℃ freeze dryer.

4. The wide-mouth manifold freeze-drying bottle configuration is easy to load and take materials, and can be connected with the imported standard freeze-drying bottle valve. 6 tubes are standard.

5. Optional power distribution defrosting function to accelerate the defrosting speed and shorten the drying cycle.

6. Vacuum pump is optional.

| Model | KD-18ND | |

| Specification | Gland multi-manifold | |

| Freeze-dried area(㎡) | 0.09 | |

| Water catching capacity(kg/ time) | 6 | |

| Vial bottle bottling | Φ12mm | 990 |

| Φ16mm | 349 | |

| Φ22mm | 184 | |

| Number of eggplant bottles | 8 | |

| Ampoule interface | / | |

| Disk loading solution(L) | 1 | |

| Material tray size(mm) | Φ200 | |

| Material spacing(mm) | 70 | |

| Material tray size( 个) | 3 | |

| Cold trap size(mm) | Φ300×405 | |

| Cold trap minimum temperature(°C) | ≤-56 ( No load) | |

| -80°C cold trap minimum temperature(°C) | ≤-80 ( No load) | |

| Ultimate vacuum(Pa) | ≤5 ( No load) | |

| PowerKw(220V50Hz) | 1.42 | |

| Ambient temperature(°C) | ≤25 | |

| Overall dimensions(mm) | 670*525*910+480 | |

| -80°C overall size(mm) | 780*525*910+480 | |

| Total Weight(kg) | 91 | |

| Special Note | The size and weight of the whole machine do not include the external vacuum pump. The height of the B/D lyophilizer does not include the manual gland handle (the height is about 70mm) | |

1.How will you delivery these goods?

It will be decided according to your quantity. Normally we will choose International Express, Air and sea.2.What is the lyophilization area of the laboratory freeze dryer?

The freeze-dry area of the conventional bell-type freeze dryer is 0.125 ㎡, and the freeze-dry area of the gland-type bell-type freeze dryer is 0.125 ㎡.3.What type of freeze dryer do you have?

Laboratory freeze dryers can be divided into bell-type freeze dryers and in-situ freeze dryers.The bell-type freeze-drying machine can be divided into ordinary type, gland type, ordinary multi-manifold, and gland multi-manifold.

The in-situ freeze dryer can be divided into an electric heating in-situ freeze dryer and a silicone oil heating in-situ freeze dryer.

4.How to choose a desktop freeze dryer and a vertical freeze dryer?

If you need lyophilized materials that require temperatures above -56 ° C and require less lyophilized material, you can choose a desktop freeze dryer to reduce costs.If you need a lot of lyophilized material and have higher requirements on the cooling temperature, you can choose the vertical freeze dryer, although the price will be more expensive, but definitely worth the money.