-

WhatsApp

-

Email

Various fields where the production of a free powder sample is required. LPG-5L has successfully processed samples in the following areas: Beverage, Flavours and colourings, Milk and egg products, Plant and vegetable extracts, Pharmaceuticals, Synthetics Heat sensitive materials, Plastics polymers and resins, Perfumes, Blood, Ceramics and superconductors Biochemicals, Dyestuffs, Soaps and detergents, Foodstuffs, Adehesives, Oxides, Textiles, Bones, Teeth and tooth amalgam and many others.It is suitable for use developing and producing trace powder in laboratory.

Features:

304 stainless steel

Touch screen

PID intelligent control

Evenly heated

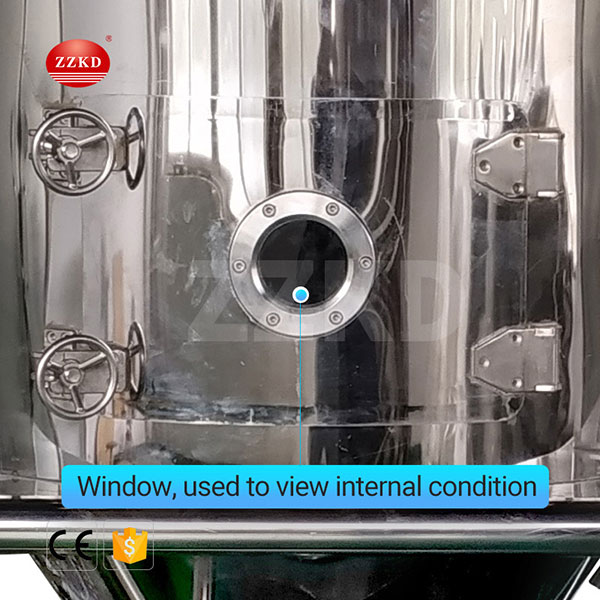

2.Window,used to view internal condition

3.Peristaltic pump

4.Air-hammer

5.Door locks,used to open and lock the door by rotating both locks

6.Efficient volute cyclone separator,used for material recovery

7.Quick opening valve,used to collect materials continuously during continous experiment.

8.Material barrel

9.2.2kw high-power booster fan

Application:

1.Special protection function,the fan will not start and the heater will not start.

2.Built-in imported oil-free air compressor with noise less than 50db.

3.Equipped with air inlet filter to ensure sample purity.

4.Dried product has uniform particle size,more than 95% of the dry powder is at the same particle size.

Details:

Upgrade touch screen

10-inch HD touch screen control

Used to control equipment operation

Facilitage the observation

Window,used to view internal condition.

High efficiency

Efficient volute cyclone separator

With above 95% actrual collection efficiency.

Bipolar spiral hot air distributor,and more even hot air flow.

304 stainless steel

Equipment material:304 stainless steel

Inside diameter of drying chamber is up to 1m and the high quality mirror design is to reduce sticky material.

Brand:LPG-5L

Material:Solution(include some suspension liquids)

Max water evaporation capacity of host machine:About 6L/h

Inlet air temperature:From room temperature to 330℃

Heating method:Electrical heating

Drying method:centrifugal atomization

Equipment material:304 stainless steel

Installation site:Indoor

Working voltage:380v 50-60hz

Floor area(length,width and height):2.0mx1.3mx2.15m

Spray drying technology began in 1920s and has undergone nearly a century of development.Spray drying technology has become the mainstream technology in the field of drying because of its special advantages, which can be obtained directly from solution or suspension system. It plays a very important role in the field of industrial and agricultural production and processing.Its typical application examples are the production of milk powder and egg powder in the food industry, the production of disperse dyes in the chemical industry, and the removal of sulfur dioxide from the flue gas generated by coal combustion in energy production.

With the development of technology, spray drying technology has been applied to animal products. Especially animal products as a major category of food, spray drying technology has been gradually applied to produce various drying products, and the food industry has made considerable progress.

Spray drying technology

Spray drying is a method used for drying materials. The technology can directly produce material solution, suspension or emulsion into powder or granule, save evaporation and comminution, shorten process extraction time and improve efficiency.In the drying process, the moisture is quickly removed and the drying time is short, which ensures that the materials will not be denatured due to high temperature. It is suitable for losing a large part of active substances, such as protein, vitamins and some flavor substances, due to the influence of high temperature, extrusion, grinding and other factors in the processing process.

Technical principle of spray drying

Spray drying is a process of dispersing liquid material into tiny droplets by atomizer and aggregated rapidly evaporating solvent to form dry powder under high temperature and hot air.Generally, spray drying can be divided into 3 stages: liquid atomization, material drying and gas solid separation.In the spray dryer, the materials that must be dried will be suspended in the air, that is, the liquid becomes atomized atomization with large surface area, and atomizing liquid will be exposed to the steam hot air in the drying chamber.The liquid evaporates rapidly, the solid is recovered as powder, and there are small hollow spherical parts.