-

WhatsApp

-

Email

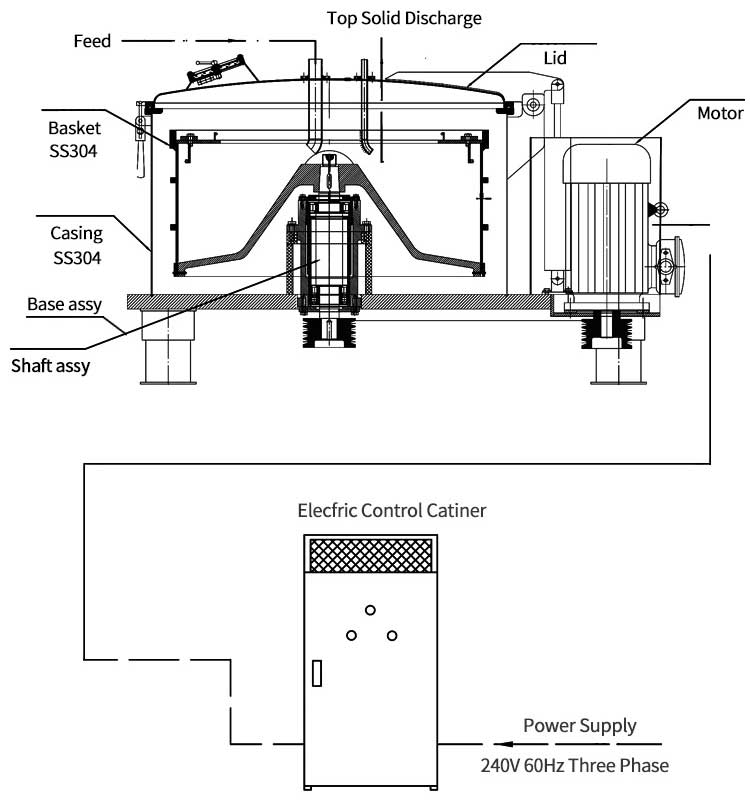

Large industrial centrifuges use centrifugal force as the driving force, forcing materials to accelerate filtration, sedimentation or separation. It is composed of feeding, washing, dewatering, enclosing knives, and discharging. Use them to complete the separation process of the entire material.

Features

- Start with an inverter, smooth start, the adjustable separation factor

- Damping method using high viscosity liquid damping oil.

- The structure design is reasonable, which effectively eliminates dead spots in hygiene. The structural parts are smooth, and the surface is polished. The external structural parts, fasteners and drums are made of stainless steel.The shell is a flip type, which can thoroughly clean the centrifuge shell and the mezzanine space of the drum.Meet the requirements of the equipment in the GMP specification.

- Equipped with a cleaning and spraying system, which can perform on-line cleaning of the centrifuge, cleaning the invisible parts of the centrifuge, such as the inner wall of the centrifuge shell, the inner and outer surfaces of the drum, and the surface of the sump.

- Simple structure, easy operation and maintenance.

- Grains are not easily broken.

- Equipped with a nitrogen protection system to ensure that the inner cavity of the centrifuge is isolated from the outside air.

- Strong versatility and wide application.

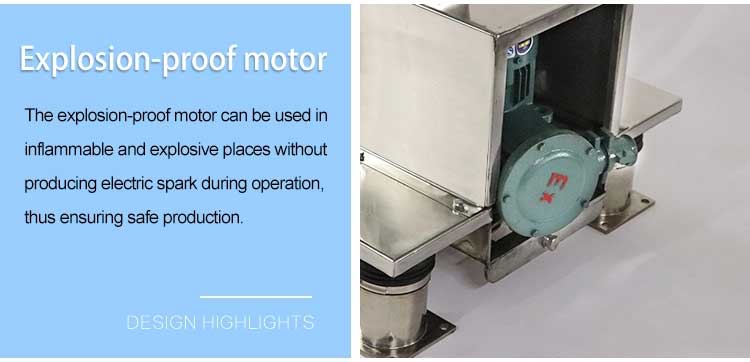

- Sealed structure, the seal adopts silicone rubber or fluorine rubber, which can realize the requirements of sealed explosion-proof.

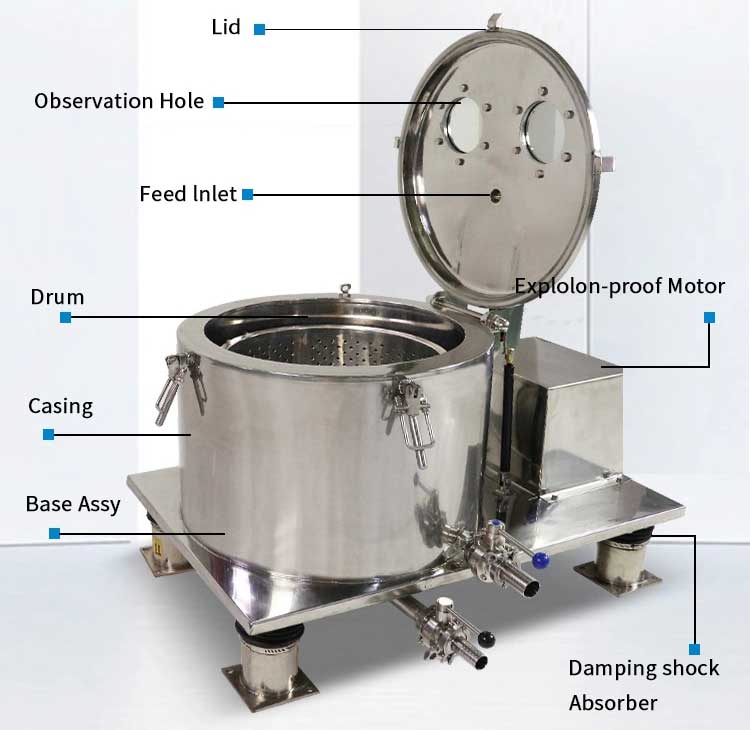

Detail

Working principle and role of large centrifuge:

Centrifugal force is used as the driving force to force the material to accelerate the filtration, sedimentation or separation of equipment called a centrifuge. According to the separation process of centrifuges, they are generally divided into centrifugal filtration and centrifugal sedimentation. Centrifugal separation relies on the drum rotating at high speed so that the liquid inside is separated by centrifugal force or attached to the cylinder wall.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. When the industrial centrifuge is in operation, if one of the following situations occurs, it should be stopped immediately for inspection:

-Abnormal vibration occurs.-Impact and abnormal sounds occur.

-The drainage holes are clogged and no filtrate is seen.

-The motor current exceeds the rated value.

-Overload operation.

-The brakes have failed.

-When the case fixing screws are loose.