-

WhatsApp

-

Email

Features of muffle furnace oven

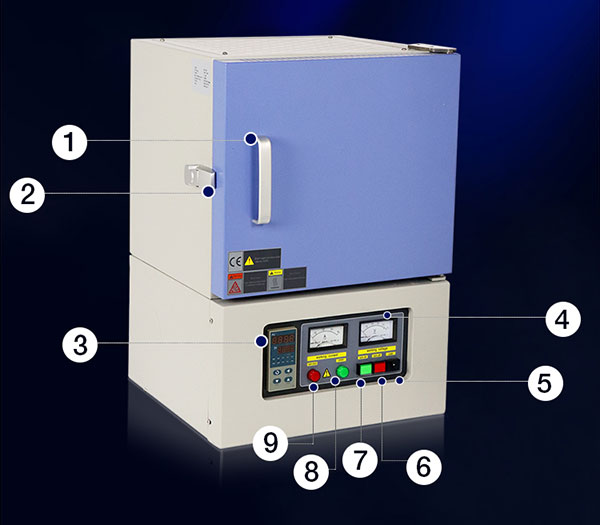

Component of muffle furnace oven

1.Furnace door

2.Lock

3.Temperature control table

4.Working voltage

5.Lock

6.Turn-off

7.Turn-on

8.Power

9.Open circuit

Performance characteristics

The furnace body is a one piece structure with a doule layer furnace shell,which can achieve air circulation and heat insulation;the surface of high quality carbon steel is used for rust removal and electrostatic spraying,which meets international laboratory standards.

Products parameters of muffle furnace oven

Model : KD-BR-12N,KD-BR-14S,KD-BR-17M

Furnace size(mm) : 100x100x100,200x200x200,300x300x300,300x300x400,400x400x400,Customize.

Maximum temperature ℃ : 1200,1400,1700

Operating temperature ℃ : 1100,1300,1600

Heating rate ℃/min : 20,15,15

Temperature control accuracy : ±1,±1,±1

Heating element : Molybdenum resistance wire, silicon carbide rod,silicon molybdenum rod

Rated voltage : 220V,380V.

Details of muffle furnace oven

Safety and environmental protection,in line with international industry standards

Strictly control quality and pursue excellence

Suffcient inventory,ready to ship

Careful packaging and worry-free transportation

Model : KD-BR-12N,KD-BR-14S,KD-BR-17M

Furnace size(mm) : 100x100x100,200x200x200,300x300x300,300x300x400,400x400x400,Customize.

Maximum temperature ℃ : 1200,1400,1700

Operating temperature ℃ : 1100,1300,1600

Heating rate ℃/min : 20,15,15

Temperature control accuracy : ±1,±1,±1

Heating element : Molybdenum resistance wire, silicon carbide rod,silicon molybdenum rod

Rated voltage : 220V,380V.

1. What is a muffle furnace oven?

The muffle furnace is a general heating equipment, which can be divided into box furnace, tube furnace and crucible furnace according to the appearance and shape.

2.What is the maximum temperature of your muffle furnace oven?

The maximum temperature can reach 1700℃。

3.What is the voltage of your muffle furnace oven?

There are two kinds of 220V and 380V.

4.What model does your muffle furnace oven have?

There are three models: KD-BR-12N, KD-BR-14S, KD-BR-17M.

5.Which industries can the muffle furnace oven be applied to?

(1)Thermal processing, industrial workpiece processing, cement, building materials industry, thermal processing or treatment of small workpieces.

(2)Pharmaceutical industry: used for drug inspection, pretreatment of medical samples, etc.

(3)Analytical chemistry industry: as sample processing in water quality analysis, environmental analysis and other fields. It can also be used for petroleum and its analysis.

(4)Coal quality analysis: used to determine moisture, ash, volatile content, ash melting point analysis, ash composition analysis, element analysis. It can also be used as a general-purpose ashing furnace.

6.What are the precautions for using the muffle furnace oven?

(1)When the muffle furnace is used for the first time or after a long period of inactivity, it must be oven-baked.

(2)The muffle furnace and controller must work in a place where the relative humidity does not exceed 85%, and there is no conductive dust, explosive gas or corrosive gas.

(3)The muffle furnace controller should be limited to use in the ambient temperature range of 0-40 ℃.

(4)Do not pull out the thermocouple suddenly at high temperature to prevent the jacket from bursting.

(5)Always keep the furnace chamber clean and remove oxides in the furnace in time.