-

WhatsApp

-

Email

Vacuum ovens for drying:

The vacuum drying oven is equipped with the patented Servotherm direct heat transfer system, which heats the entire inner chamber with highly efficient heating elements installed inside and outside the chamber. Heat is conducted from the chamber to the shelving brackets and precision-milled aluminum cabinets. Heat is then transferred from the cabinet to the load for fast, protected and efficient drying of media and solvents. Epoxy resins were degassed using an empty vacuum ovens for drying VO 400 as standard equipment in the manufacture of electronic modules to find a way to remove voids before curing. Check out our Agilent Varian frequency controlled oil sealed rotary vane and dry scroll vacuum pumps. When the oven reaches a vacuum, the pump slows down and runs surprisingly quietly. This saves electricity and makes the laboratory a fair research and analysis library. The added advantage is that the variable frequency pump runs cooler, provides much less heat to the lab, and requires less service because the lower rpm doesn't cause a lot of mechanical wear on the pump elements. When this operation was performed on a larger scale, it was identified as vacuum drying. Drying is a recurring requirement in the agricultural, pharmaceutical and food industries. Laboratory equipment vacuum drying oven are often used for delicate drying processes, such as eliminating flammable solvents or drying tiny elements. The inside of the vacuum drying oven is equipped with a fan and an exhaust system to blow hot air around the heated item before it is exhausted. Unlike other ovens, it doesn't cook items from the top. Instead, it distributes heat more evenly.

The use of vacuum drying oven:

One of the more fascinating uses of vacuum ovens for drying is the function they play in preparing components for family trips. Our mechanical parts that are exposed to the vacuum of space need to be degassed in a vacuum oven beforehand. If you skip this necessary step, you may suddenly have half of the gas out as it hits the vacuum of space and disintegrates. Both BINDER vacuum drying chamber models allow for efficient drying without residue or damage to the fabric being dried. With their proven technology options, they excel in meeting the stringent demands of commercial and scientific laboratories. Vacuum technology is used to remove moisture from any wet solids and dry them.

When you control important variables like temperature and pressure, you can prevent certain chemical reactions from happening. For example, we can use a vacuum oven to prevent oxidation on the surface of selected metal halves or oxidation of certain pharmaceutical commodities. Vacuum strain controllers can be added to vacuum ovens to help optimize the vacuum drying process and provide a gentler drying process. Modern vacuum controllers offer recipe management in addition to precise ratio management and venting.

In an industrial setting, some samples are often finer than others. The operation of the vacuum drying oven has minimized this threat. The vacuum drying oven can be programmed with one of the many heating and laboratory equipment vacuum drying oven via a mouse or touchpad on a laptop. Each oven has a high temperature connector on the rear of the unit that allows single-phase energy connection according to country-specific methods and IEC standards. Adjustment of the three calibration values for temperature and other specific parameters can be done instantly on the digital control screen.

Unlike other ovens, it doesn't cook dinner gadgets from the top; instead, it distributes heat more evenly. These ovens rely on convection technology to achieve environmentally friendly heat switching through the rapid movement of physical air. For this purpose, they are often singled out by manufacturers for normal use.

Material of vacuum drying oven:

Our turnkey 2, 5 and 10 vacuum purge kits contain all the little things you want in the hottest vacuum oven + pump + hookup configuration. Unlike other lab ovens, adding extra gadgets won't cause the temperature to drop. Their basic function is to create a setting that maintains and controls an elevated temperature within a specific range. Laboratory ovens are used for a wide range of industrial purposes. Some of their common uses include annealing, die bond curing, drying, polyimide baking, and sterilization.

Based on the assessed knowledge, the controller can make continuous changes to the input values, similar to heating depth or cooling, to optimally regulate internal chamber conditions. Additionally, the controller can quickly ramp up to precise temperature setpoint levels without overshooting, minimizing the time required to meet set process parameters. The result is a reduction in general cycle time, energy consumption and recovery time after opening the chamber door. Vacuum ovens are ideal for removing residual water, solvents or other volatile compounds from temperature-sensitive products. Vacuum ovens for drying remove unwanted molecules by reducing the strain in the oven.

Likewise, for situations where friction from transferring air can damage the sample or process. All the same physical principles are at play when residual solvent or water is drained from the extracted cannabis oil. By reducing the pressure inside the vacuum furnace, the trapped water and solvent will turn from liquid to fuel and be pulled out of the chamber, discarding the purified, stabilized oil. +50C temperature operation, and +195C temperature program operation are two different function programs in your test work.

laboratory equipment vacuum drying oven:

The greater the heat, the more the bonds are opened, and the excess liquid water turns into water vapor. The trick is to create enough heat to transfer the water out without burning the desired material. The first is to stay away from questions that contain different forms. Heat is the enemy of a variety of disparate volatiles and organic samples. Oxygen oxidation introduced during drying can also lead to a reduced lifespan or major errors in some objects. Shelf brackets for stainless steel chambers are removable for easy cleaning and sterilization of the entire chamber.

Vacuum drying cabinets are heated directly on each adjustable thermal shelf for optimum temperature distribution and fast vacuum drying. All objective laboratory equipment vacuum drying oven feature enhanced safety options, programming features and pump storage compartments. Available in bench-top or floor-standing footprints, multiple capacities and optional inert fuel circulation.

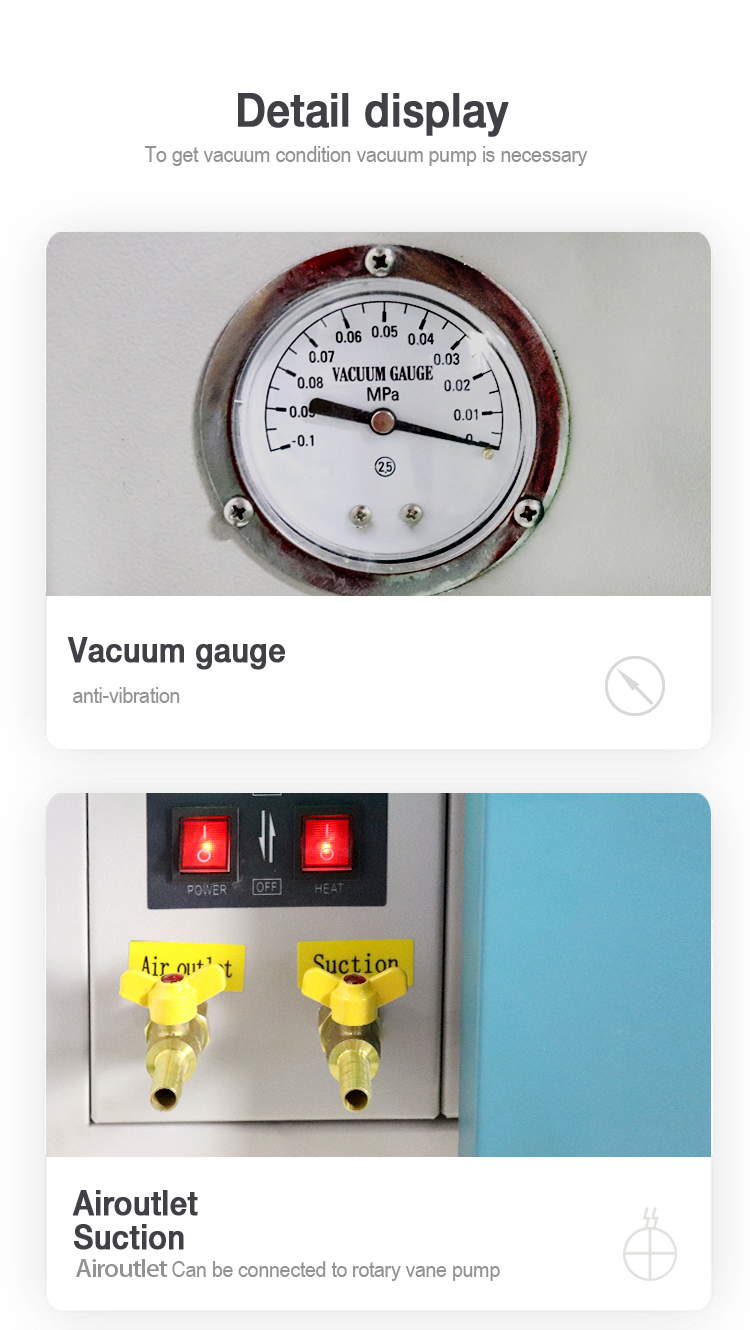

In a vacuum drying oven, heat treatment takes place in a sealed chamber, using an external vacuum pump to set the desired vacuum stage. Using a vacuum oven, the entire application can be performed under vacuum or in a controlled environment by introducing inert gasoline. A vacuum oven can help prevent surface reactions, properly decontaminate samples, and speed up the outgassing process. In smaller laboratory scale environments, our ovens are used for analytical functions in R&D facilities and universities. If you are drying, softening, curing or sterilizing products, you can choose an oven to get the job done in a laboratory setting. Cascade offers vacuum ovens and laboratory ovens to remove moisture, solvents and other contaminants from products. There are several key variations between vacuum drying and forced air drying, but in principle a vacuum oven is best for temperature-sensitive goods. Vacuum ovens utilize pressure changes at temperatures that do not damage the product to remove unwanted compounds.

When the tried and true method becomes part of the problem, the easy options are thrown away from the start. Our team of experts has joined forces to provide you with a comprehensive guide on how to buy a quality autoclave. Get advice on planning ahead, a guide to the utilities you need, a breakdown of common options and configurations, and more. Our customer support team is ready to assist you with product selection advice, sales estimates, replacement parts, equipment, customization, product literature, and more.